Close

| Name of a product | Inventory number | Producer | YOM | Parameters | ||

|---|---|---|---|---|---|---|

|

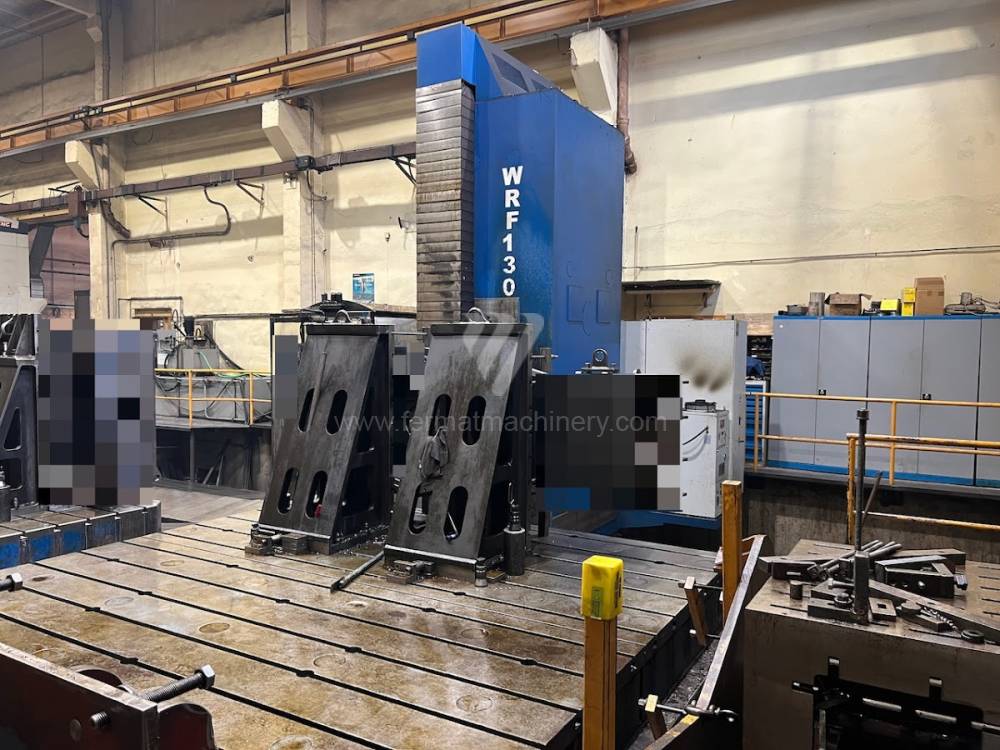

WRF 130 CNC |

231250 | Fermat | 2008 | Control system Heidenhain: TNC 530 Diameter of working spindle: 130 mm Travel X-axis: 8000 mm Travel Y-axis: 3000 mm Spindle speed: 10 - 3000 /min. Spindle travel - W axis: 730 mm |

|

|

W 100 A |

191457 | TOS Varnsdorf | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 7 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

||

|

W 100 A |

251737 | TOS Varnsdorf | 1995 | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 0 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

|

|

W 100 A |

251853 | TOS Varnsdorf | 2004 | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 0 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

|

|

40T |

182013 | Lucas | 2018 | Control system Fanuc: 0i-MF Diameter of working spindle: 130 mm Travel X-axis: 3657 mm Travel Y-axis: 3048 mm Spindle speed: 10 - 3000 /min. Cooling through spindle: YES |

|

|

W 100 A |

241676 | TOS Varnsdorf | 1991 | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 0 - 1200 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

|

|

W 100 A |

241881 | TOS Varnsdorf | 1992 | Diameter of working spindle: 100 mm Travel X-axis: 1500 mm Travel Y-axis: 1250 mm Spindle speed: 7 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: mm |

|

|

WH 10 NC |

251656 | TOS Varnsdorf | 1991 | Control system Tesla: NS 670 Diameter of working spindle: 100 mm Travel X-axis: 1250 mm Travel Y-axis: 900 mm Spindle speed: 16 - 1250 /min. Cooling through spindle: NO |

|

|

WHN 9 B CNC |

192075 | TOS Varnsdorf | 1982 | Control system Mefi: CNC 859 Diameter of working spindle: 90 mm Travel X-axis: 1250 mm Travel Y-axis: 900 mm Spindle speed: 10 - 1100 /min. Cooling through spindle: NO |

|

|

Rapid 1 |

251498 | Wotan | 1982 | Control system Heidenhain: TNC 426 Diameter of working spindle: 120 mm Travel X-axis: 1250 mm Travel Y-axis: 1250 mm Spindle speed: 10 - 2000 /min. Cooling through spindle: NO |

|

|

WMO B 105 MNC |

251054 | Wotan | Control system Siemens: Sinumerik 820 Diameter of working spindle: 105 mm Travel X-axis: 1800 mm Travel Y-axis: 1300 mm Spindle speed: 9 - 1000 /min. Cooling through spindle: NO |

||

|

WH 10 CNC |

171452 | TOS Varnsdorf | Control system Heidenhain: TNC 530 Diameter of working spindle: 100 mm Travel X-axis: 1250 mm Travel Y-axis: 1100 mm Spindle speed: 10 - 1200 /min. Cooling through spindle: NO |

||

|

WHN 13 P CNC |

191459 | TOS Varnsdorf | 2024 | Control system Heidenhain: TNC 640 Diameter of working spindle: 130 mm Travel X-axis: 3500 mm Travel Y-axis: 2000 mm Spindle speed: 10 - 3000 /min. Cooling through spindle: YES |

|

|

W 9 A |

261015 | TOS Varnsdorf | 1978 | Diameter of working spindle: 90 mm Travel X-axis: 1250 mm Travel Y-axis: 1120 mm Spindle speed: 10 - 1400 /min. Cooling through spindle: NO Spindle travel - W axis: 710 mm |

|

|

WH 10 CNC |

251363 | TOS Varnsdorf | Control system Heidenhain: TNC 620 Diameter of working spindle: 100 mm Travel X-axis: 1250 mm Travel Y-axis: 1030 mm Spindle speed: 16 - 2500 /min. Cooling through spindle: NO |

||

|

WFT 13 |

261140 | Fermat | 2015 | Control system Heidenhain: TNC 530 Diameter of working spindle: 130 mm Travel X-axis: 3000 mm Travel Y-axis: 2000 mm Spindle speed: 10 - 3000 /min. Cooling through spindle: YES |

|

|

WHQ 13 CNC |

261063 | TOS Varnsdorf | 2012 | Control system Heidenhain: TNC 530 Diameter of working spindle: 130 mm Travel X-axis: 5000 mm Travel Y-axis: 3000 mm Spindle speed: 0 - 3000 /min. Cooling through spindle: YES |

|

|

W 100 A |

261067 | TOS Varnsdorf | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 7 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

||

|

W 100 A |

261092 | TOS Varnsdorf | 1982 | Diameter of working spindle: 100 mm Travel X-axis: 1600 mm Travel Y-axis: 1120 mm Spindle speed: 0 - 1120 /min. Cooling through spindle: NO Spindle travel - W axis: 900 mm |

|

|

441B-72 |

251248 | Lucas | 1967 | Diameter of working spindle: 100 mm Travel X-axis: 1500 mm Travel Y-axis: 1200 mm Spindle speed: 15 - 1550 /min. Cooling through spindle: NO Spindle travel - W axis: 600 mm |

|

|

WHQ 105 CNC |

251830 | TOS Varnsdorf | 2015 | Control system Siemens: Sinumerik 840 D Diameter of working spindle: 105 mm Travel X-axis: 1800 mm Travel Y-axis: 1600 mm Spindle speed: 0 - 3300 /min. Cooling through spindle: YES |

|

|

HWC-P 110 |

261135 | DEFUM | 1967 | Diameter of working spindle: 110 mm Travel X-axis: 2400 mm Travel Y-axis: 1750 mm Spindle speed: 10 - 300 /min. Cooling through spindle: NO Spindle travel - W axis: 800 mm |

|

|

W 9 |

241843 | TOS Varnsdorf | 1975 | Diameter of working spindle: 90 mm Travel X-axis: 1000 mm Travel Y-axis: 900 mm Spindle speed: 0 - 1400 /min. Cooling through spindle: NO Spindle travel - W axis: 710 mm |

|

|

AFP 180 |

221138 | Titan | 2009 | Control system Fanuc: Fanuc 32i Diameter of working spindle: 180 mm Travel X-axis: 9130 mm Travel Y-axis: 3980 mm Z axis travel: 1900 mm/min Axis W: 1200 mm |

|

|

WH 10 NC |

241423 | TOS Varnsdorf | 1987 | Diameter of working spindle: 100 mm Travel X-axis: 1130 mm Travel Y-axis: 1250 mm Spindle speed: 16 - 1500 /min. Cooling through spindle: NO Spindle travel - W axis: 650 mm |

Horizontal boring machines are universal machines used for machining of complex products. These borers are mainly used for small batch production. For one workpiece clamping, the operation can be performed from up to five sides, either simultaneously or sequentially. A large number of standard and special accessories are available for horizontal boring machines. This makes boring machines suitable not only for boring, but also for drilling, turning, milling and other operations.

Horizontal boring machines can be divided into several types, such as: table, cross, plate, coordinate. Can be divided also according to the type of control - conventional (without system), or CNC controlled.

Table boring machines are equipped with a movable table that moves in one or two axes. Depending on this, boring machines are further divided into cross-construction or T-construction. The table is usually rotary (B axis), which allows four sides of the workpiece to be machined in one clamp. However, if the machine is equipped with an angle head (A and C axes) and the workpiece does not exceed the dimensions of the machine, five sides can be machined in one clamp. The boring milling machines differ from the table milling machines in particular by the extendable spindle (W axis). Higher series often also have a movable headstock (V axis).

These kinds of boring machines are suitable and used for machining of the largest workpieces. Headstock is moving along the vertical guide of the column and column itself is moving along the bed perpendicular to the axis of the spindle. The workpiece is clamped immovably on a cast-iron floor plate equipped with T-slots. If this floor type boring machine is equipped with a rotary table which is movable in the direction of the spindle axis, the number of controlled axes increases. Such boring machines mainly have a boring spindle diameter of 130-315 mm.

So-called coordinate boring machines are used for machining precise holes. Its design is affected by the requirements for very high accuracy of all movements, good dynamics and the best possible temperature stability. There are two types of these machines. One-column borer with horizontal or vertical spindle axis (this is for smaller sizes of workpieces that are clamped on a cross table) and two column borer with one or more vertical spindles. Workpiece is clamped on a longitudinal table, which is in between two columns along which the crosspiece carrying the work headstock moves. An optical system is usually used for measuring. More modern machines are then equipped with a CNC control system.

All types of horizontal boring machines are conventional or CNC controlled. Among the most popular producers of CNC systems are Heidenhain, Siemens, Fanuc, Fagor.

Horizontal boring machines can be also equipped with automatic tool change which is primarily used for storage of tool holders, its manipulation and positioning without participation of human factor.

Among the main and most popular manufacturers of boring mills we have to mention: FERMAT, TOS, ŠKODA, PAMA, UNION, JUARISTI, SCHARMANN, KURAKI, WOTAN.