Close

YOM:1996

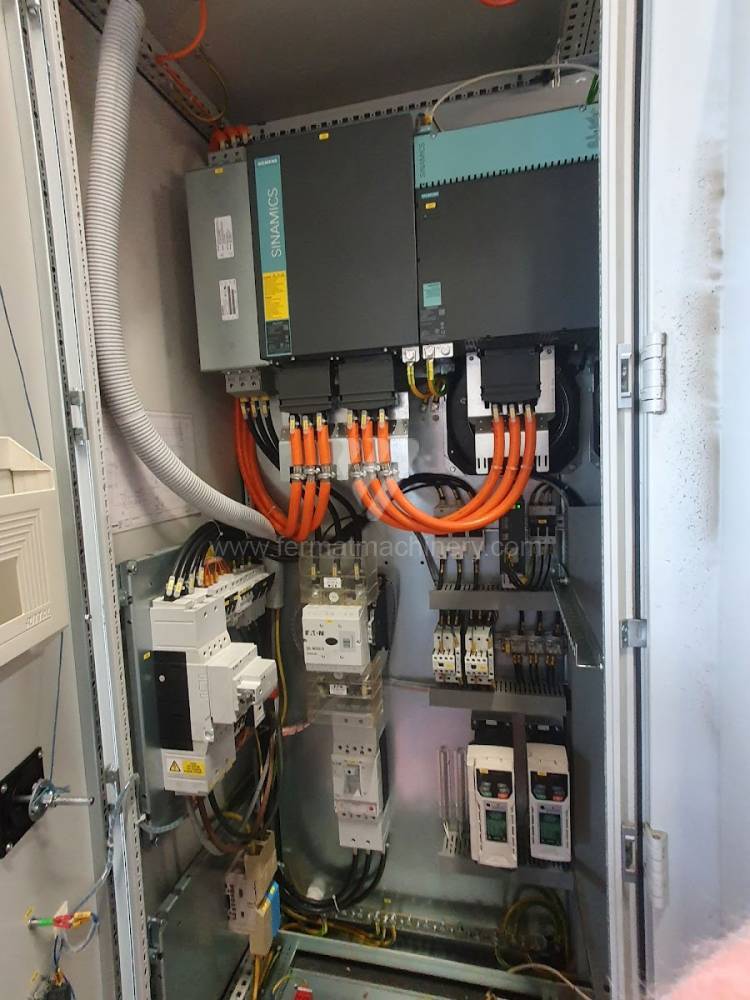

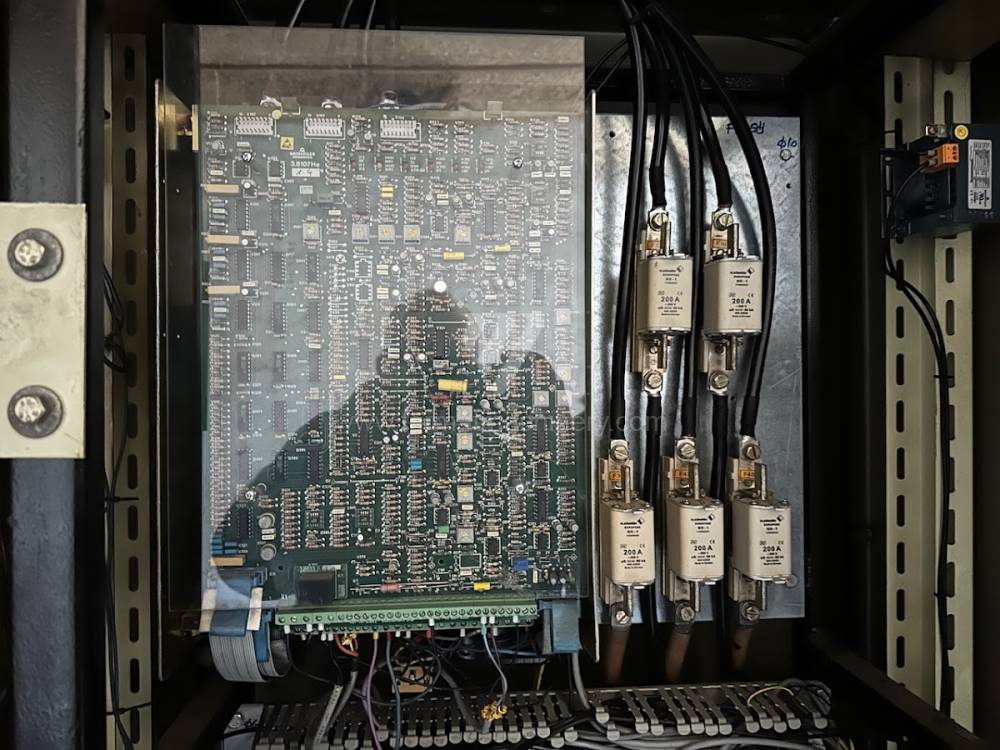

Control system Siemens: Sinumerik 840 C

Max. diameter of workpiece: 2000 mm

Clamping diameter of rotary table: 1750 mm

Max. load of table: 10000 kg

Max. workpiece height: 1500 mm

Ram travel (Z): 750 mm

YOM:2017

Control system Siemens: Sinumerik 840D Sl

Max. diameter of workpiece: 1100 mm

Clamping diameter of rotary table: 800 mm

Max. load of table: 4000 kg

Max. workpiece height: 690 mm

Ram travel (Z): 630 mm

YOM:2010

Control system Siemens: 802 D si

Max. diameter of workpiece: 3300 mm

Clamping diameter of rotary table: 3000 mm

Max. load of table: 18000 kg

Max. workpiece height: 2300 mm

Ram travel (Z): mm

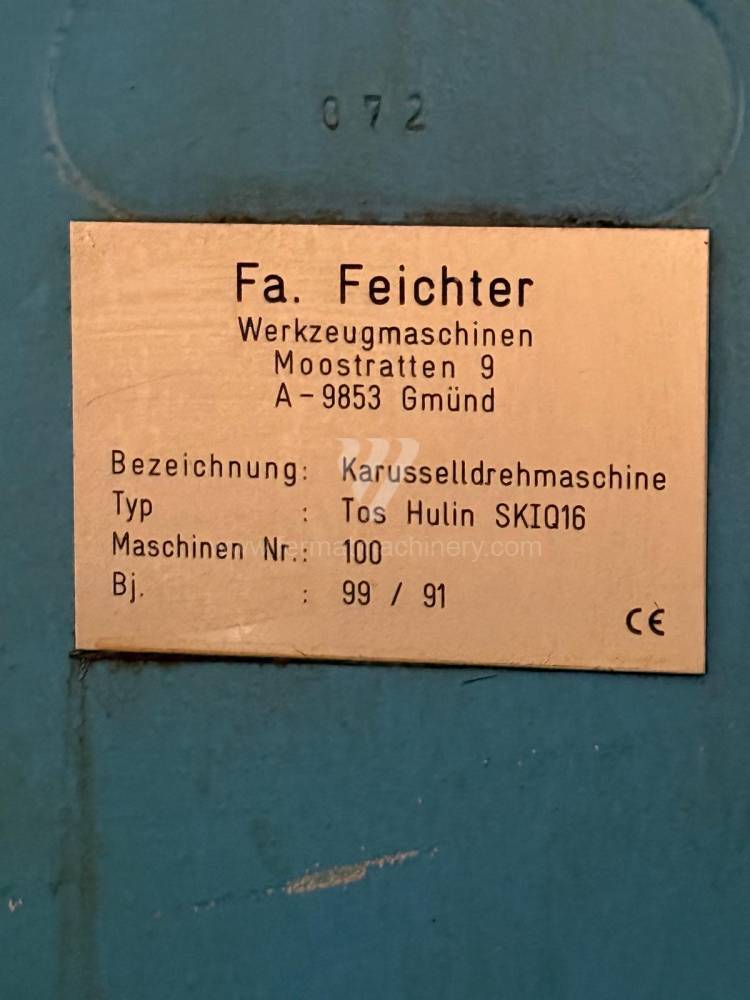

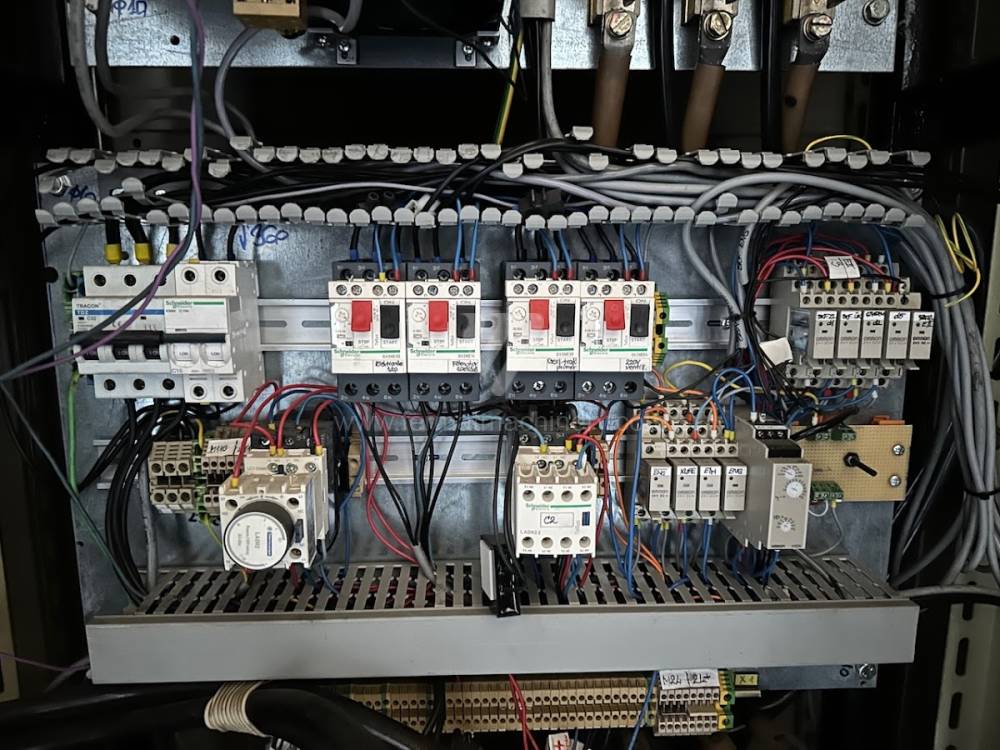

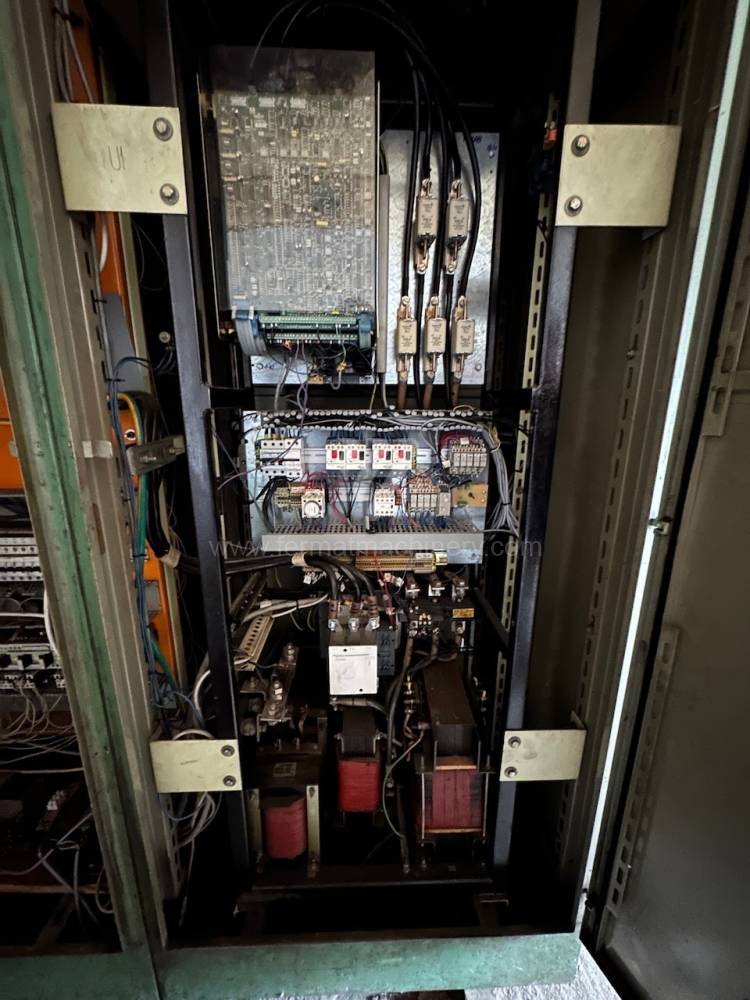

Control system NCT: 204

Max. diameter of workpiece: 1400 mm

Clamping diameter of rotary table: 1250 mm

Max. workpiece height: 1150 mm

Max. load of table: 6000 kg

Driven Tools: NO

YOM:2012

Control system Siemens: Sinumerik 840 D

Max. diameter of workpiece: 8000 mm

Clamping diameter of rotary table: 6300 mm

Max. workpiece height: 4000 mm

Max. load of table: 160000 kg

Driven Tools: NO

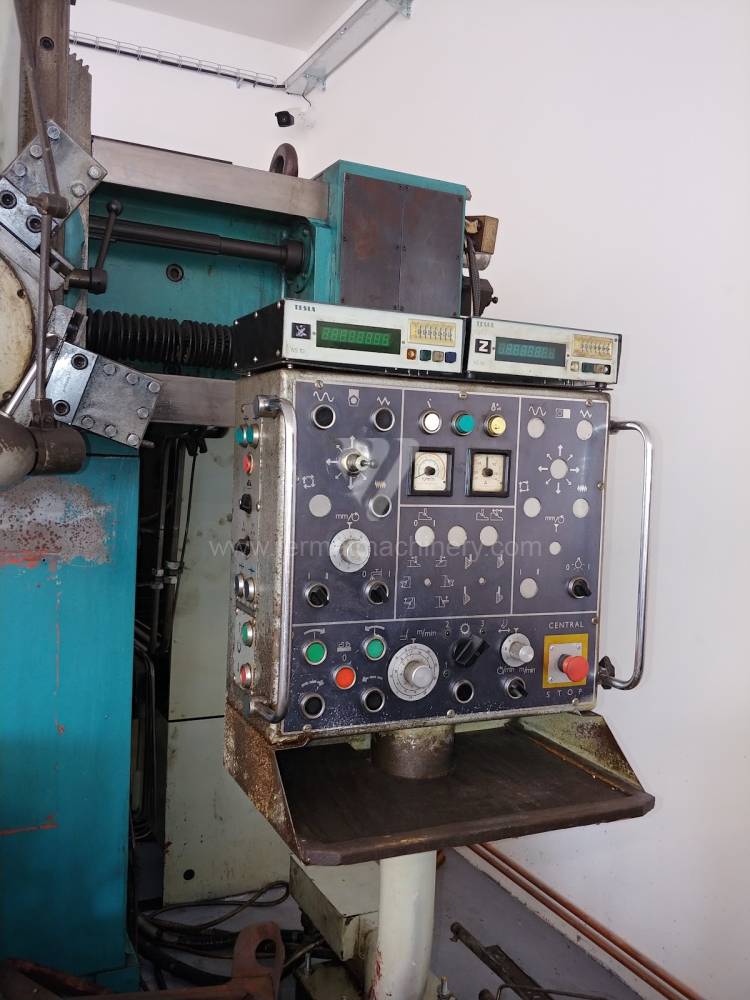

YOM:1972

Max. diameter of workpiece: 1600 mm

Clamping diameter of rotary table: 1400 mm

Max. load of table: 5000 kg

Max. workpiece height: 1000 mm

Ram travel (Z): 700 mm

Ram size: mm

Control system Tesla: NS 113

Max. diameter of workpiece: 1050 mm

Clamping diameter of rotary table: 780 mm

Max. load of table: 2000 kg

Max. workpiece height: 630 mm

Ram travel (Z): mm

Control system Fagor: 8025/8030

Max. diameter of workpiece: 1600 mm

Clamping diameter of rotary table: 1400 mm

Max. load of table: 4000 kg

Max. workpiece height: 800 mm

Ram travel (Z): mm

Max. diameter of workpiece: 2500 mm

Clamping diameter of rotary table: 2250 mm

Max. load of table: 12000 kg

Max. workpiece height: 1500 mm

Ram travel (Z): 1100 mm

Ram size: mm

Control system Fanuc: 0i-TF

Max. diameter of workpiece: 2200 mm

Clamping diameter of rotary table: 2000 mm

Max. load of table: 12000 kg

Max. workpiece height: 1500 mm

Ram travel (Z): mm

YOM:1991

Control system Siemens: Sinumerik 840 D

Max. diameter of workpiece: 2000 mm

Clamping diameter of rotary table: 1600 mm

Max. load of table: 12000 kg

Max. workpiece height: 1600 mm

Ram travel (Z): mm

YOM:1981

Control system Siemens: Sinumerik 840D Sl

Max. diameter of workpiece: 3300 mm

Clamping diameter of rotary table: 3000 mm

Max. load of table: 18000 kg

Max. workpiece height: 2300 mm

Ram travel (Z): 1700 mm

YOM:1989

Control system Tesla: NS 642 C

Max. diameter of workpiece: 1100 mm

Clamping diameter of rotary table: 800 mm

Max. load of table: 2500 kg

Max. workpiece height: 750 mm

Ram travel (Z): 630 mm

Max. diameter of workpiece: 3300 mm

Clamping diameter of rotary table: 3000 mm

Max. load of table: 18000 kg

Max. workpiece height: 2300 mm

Ram travel (Z): mm

Ram size: 224 x 224 mm

Max. diameter of workpiece: 2630 mm

Clamping diameter of rotary table: 2600 mm

Max. load of table: 15000 kg

Max. workpiece height: 1900 mm

Ram travel (Z): mm

Ram size: mm

YOM:1983

Max. diameter of workpiece: 2150 mm

Clamping diameter of rotary table: 2000 mm

Max. load of table: 12 000 kg

Max. workpiece height: 1500 mm

Ram travel (Z): 1300 mm

Ram size: 250x250 mm

Control system Siemens: Sinumerik 840 C

Max. diameter of workpiece: 2400 mm

Clamping diameter of rotary table: 2200 mm

Max. load of table: 17000 kg

Max. workpiece height: 1800 mm

Ram travel (Z): 1500 mm

YOM:1982

Control system Tesla: NS 560

Max. diameter of workpiece: 1000 mm

Clamping diameter of rotary table: 800 mm

Max. load of table: 2500 kg

Max. workpiece height: 720 mm

Ram travel (Z): 630 mm

YOM:1999

Control system Fanuc: 16i - T

Max. diameter of workpiece: 1800 mm

Clamping diameter of rotary table: 1600 mm

Max. load of table: 12000 kg

Max. workpiece height: 1275 mm

Ram travel (Z): 1000 mm

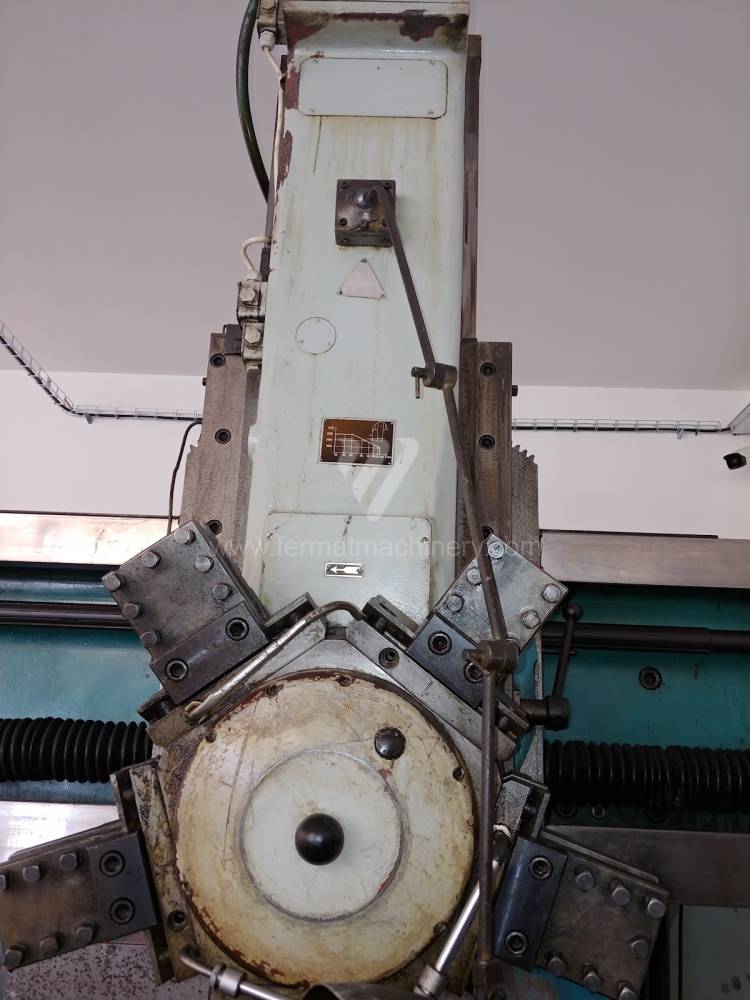

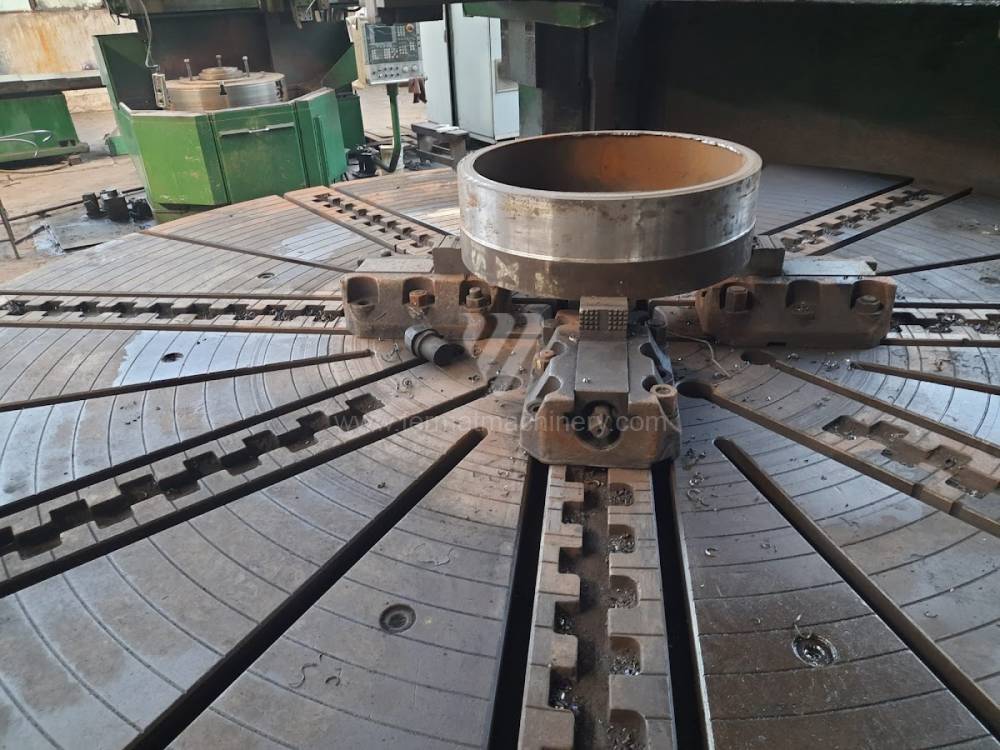

Vertical lathe is used for chip machining. During this process the workpiece is clamped in a horizontal position on the clamping plate with manual or hydraulic chucks.The axis of the rotation of the clamped part is vertical.

Vertical lathes are therefore primarily used for turning of large and heavy workpieces.

Both rotating and non-rotating components can be machined and clamped. Vertical lathes enable turning of frontal, cylindrical, conical and general rotary internal or external surfaces. Also turning of internal and external threads on cylindrical and conical surfaces with constant and variable pitch.

If accessories are used, other operations are also possible.

Machine which is equipped with C axis and live tools is possible to use direct rotary heads for milling. This enables them to drill holes, but also cut threads or mill grooves of general shapes. The machine can be also equipped with angle head which allows drilling, milling and threading at different angles relative to the axis of the clamping plate. Another possibility is to use a grinding device for frontal and peripheral grinding of internal and external surfaces.

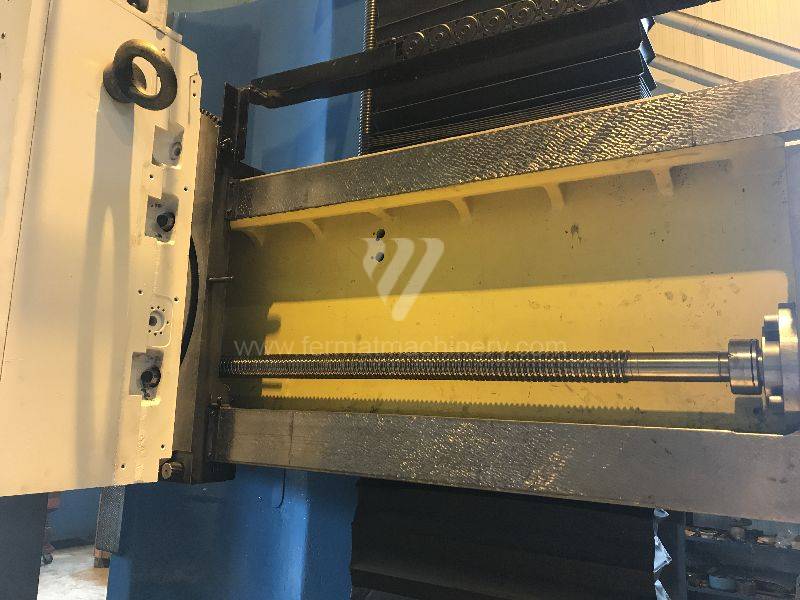

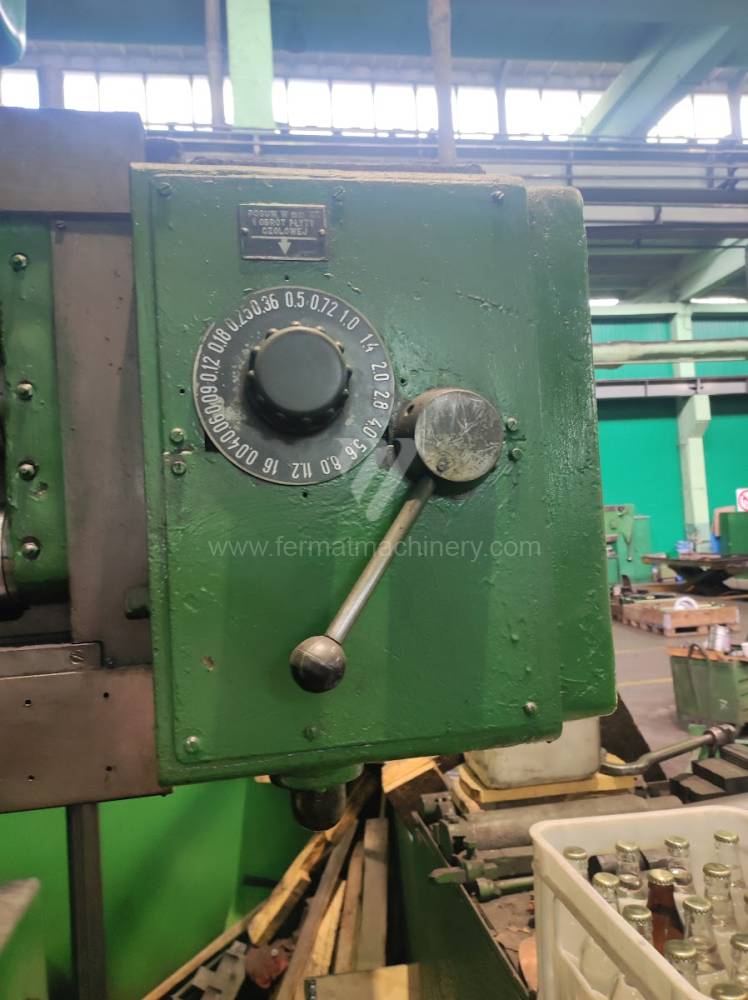

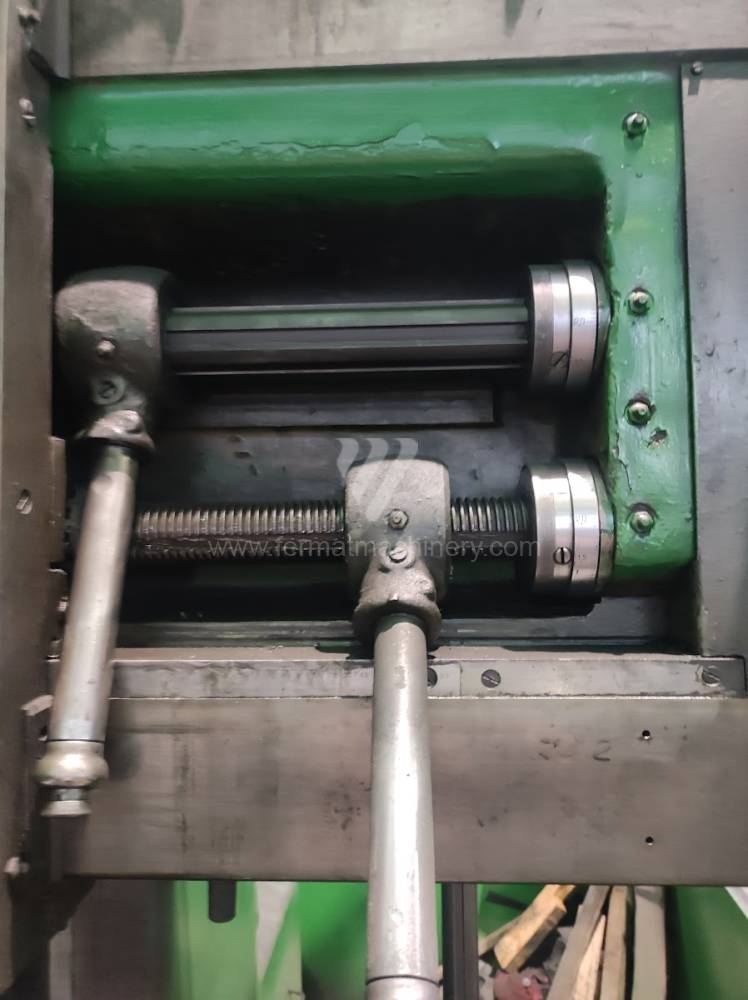

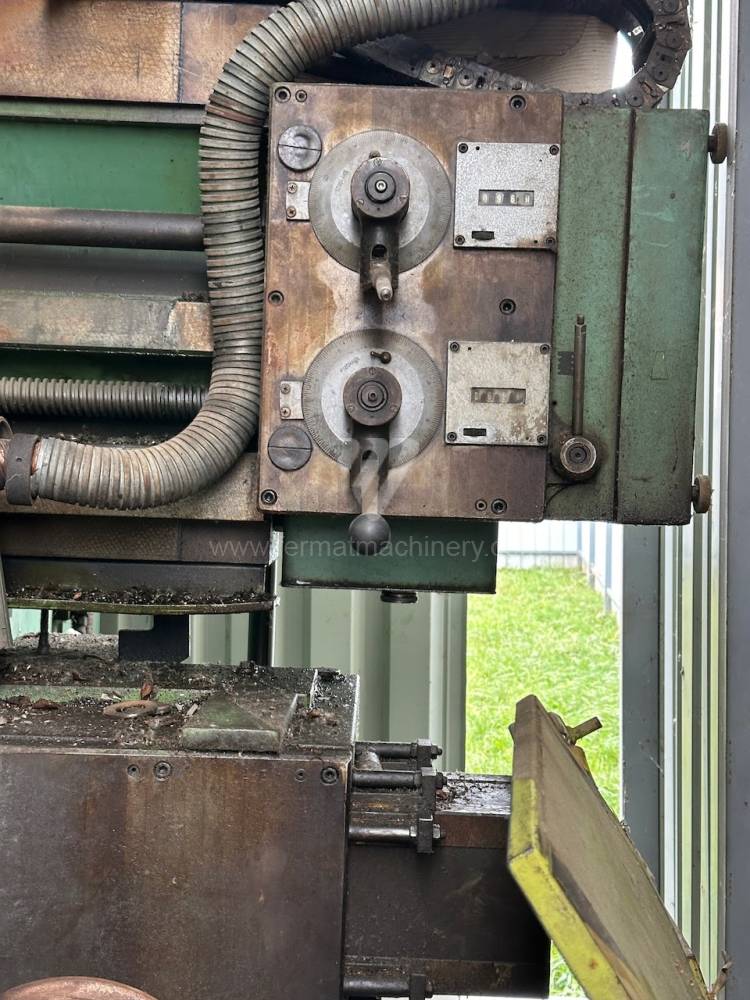

The height of the workpiece is determined by setting the position of the crossrail and the maximum slide out of the ram (axis Z).

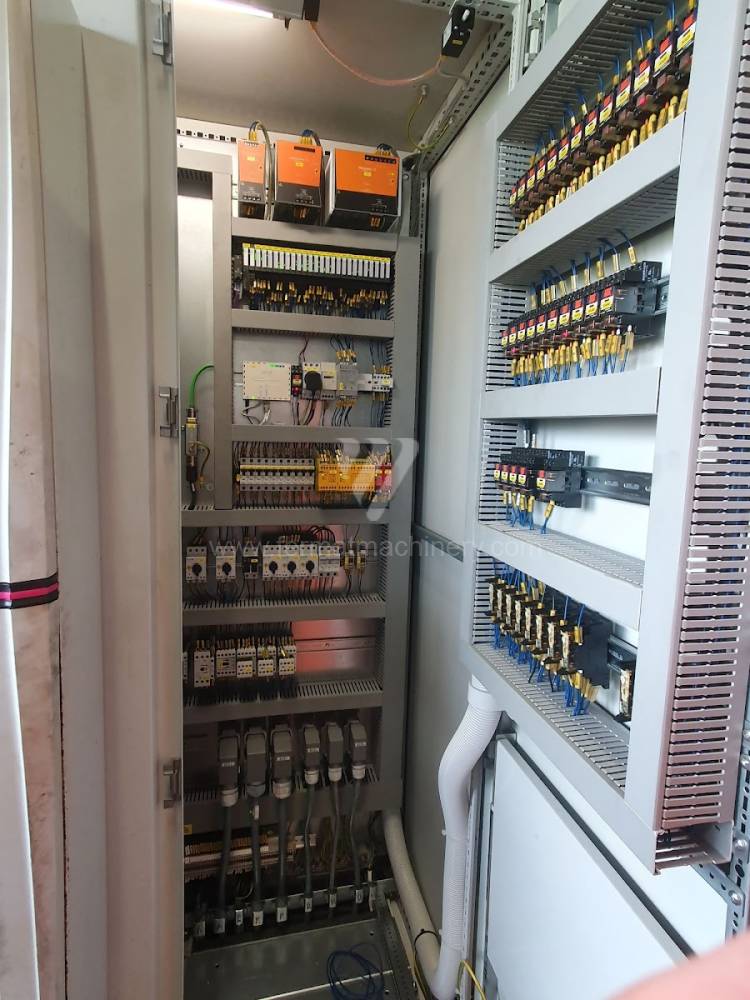

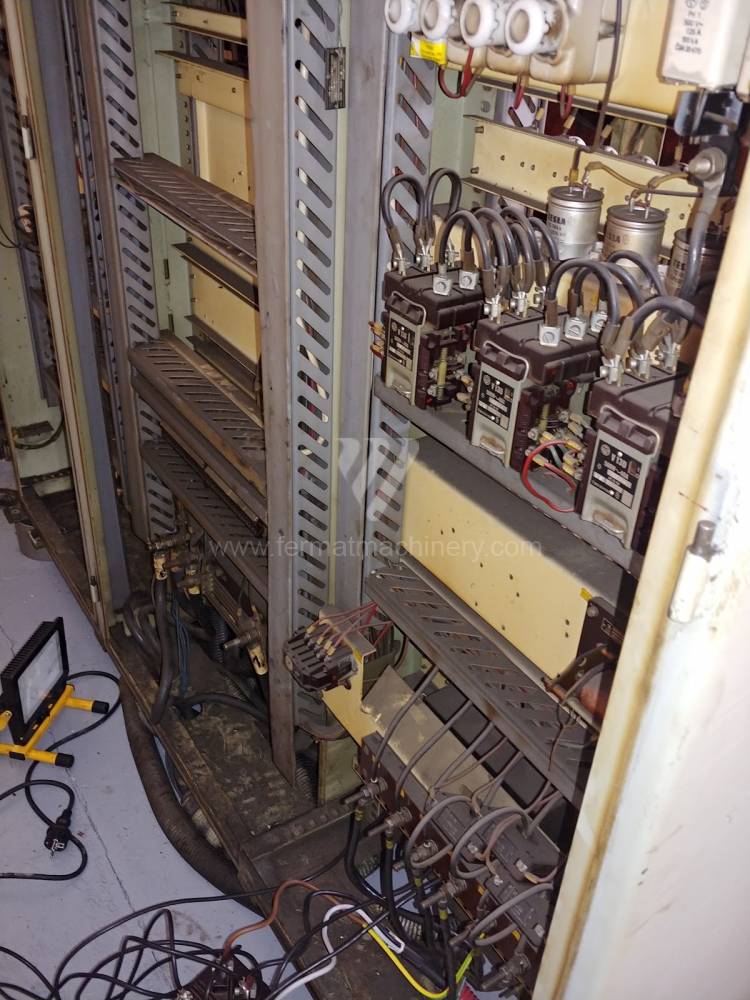

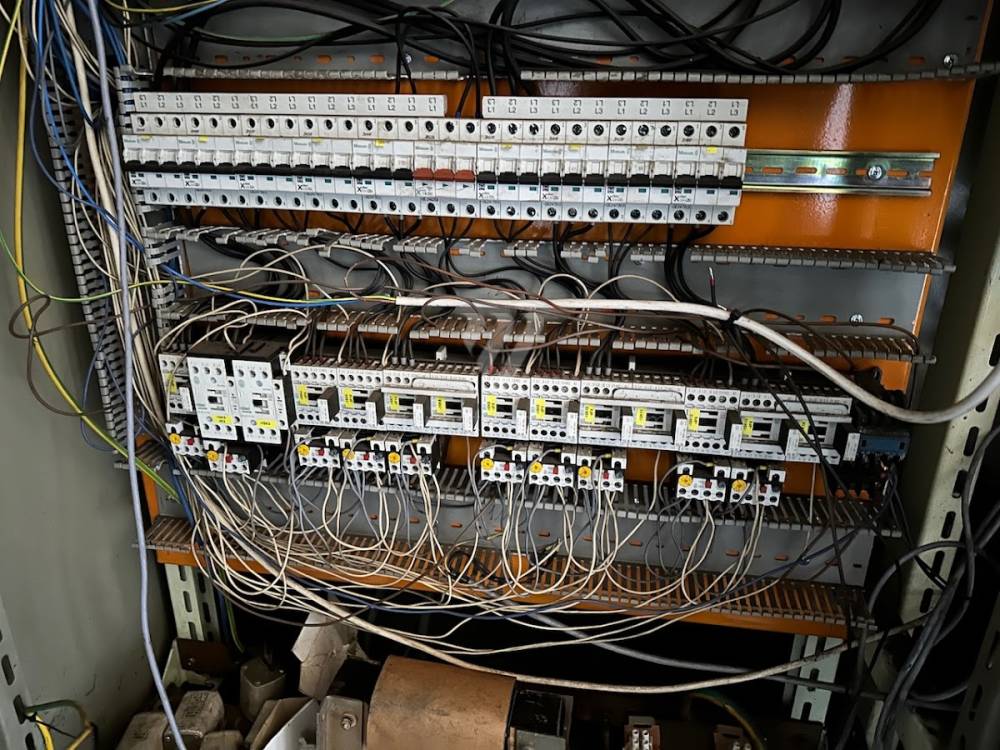

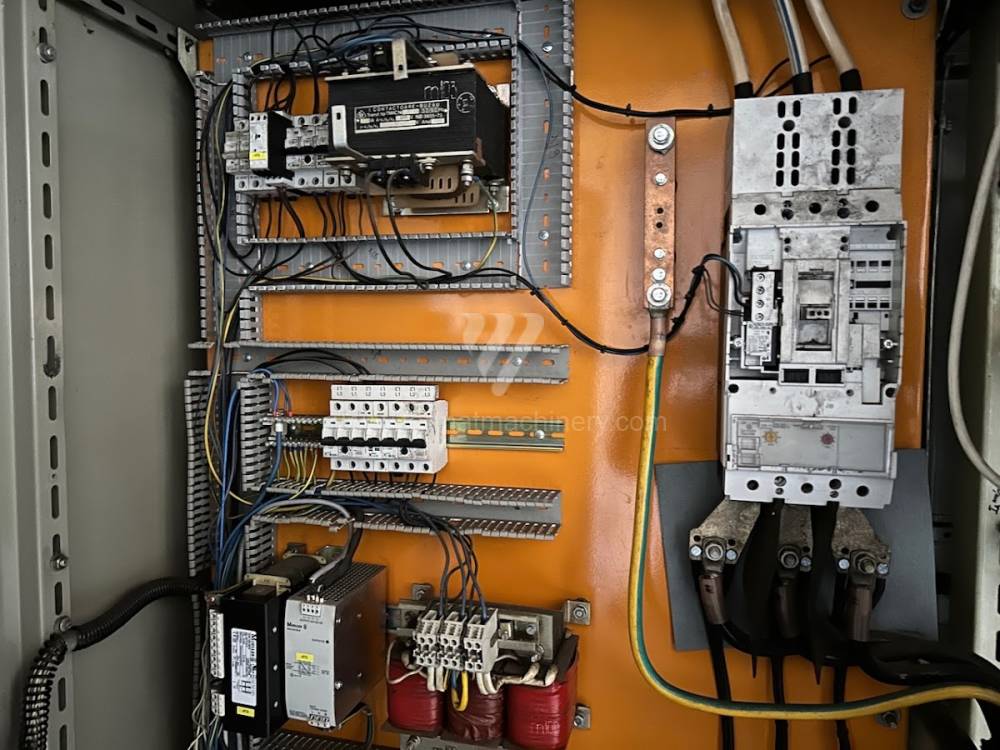

Among other main parts of vertical lathes are: crossrail, ram, clamping plate, beds, column, turning tool holders, straight and angular rotation heads, cooling of tools, water management, chip conveyor. The machine cover then ensures the safety of the machine operator.

TOS HULIN a.s., ČKD Blansko, OMOS Blansko, PIETRO CARNAGHI, SORALUCE, YOU-JI, YU SHINE, Doosan, Mazak, SCHIESS, RAFAMET, DMG MORI, Berthiez, Titan, Dorries, Morando and many others.