Close

Turn table diameter: 400 mm

Turning lenght: 640 mm

Sloping bed: YES

Spindle bore: 40 mm

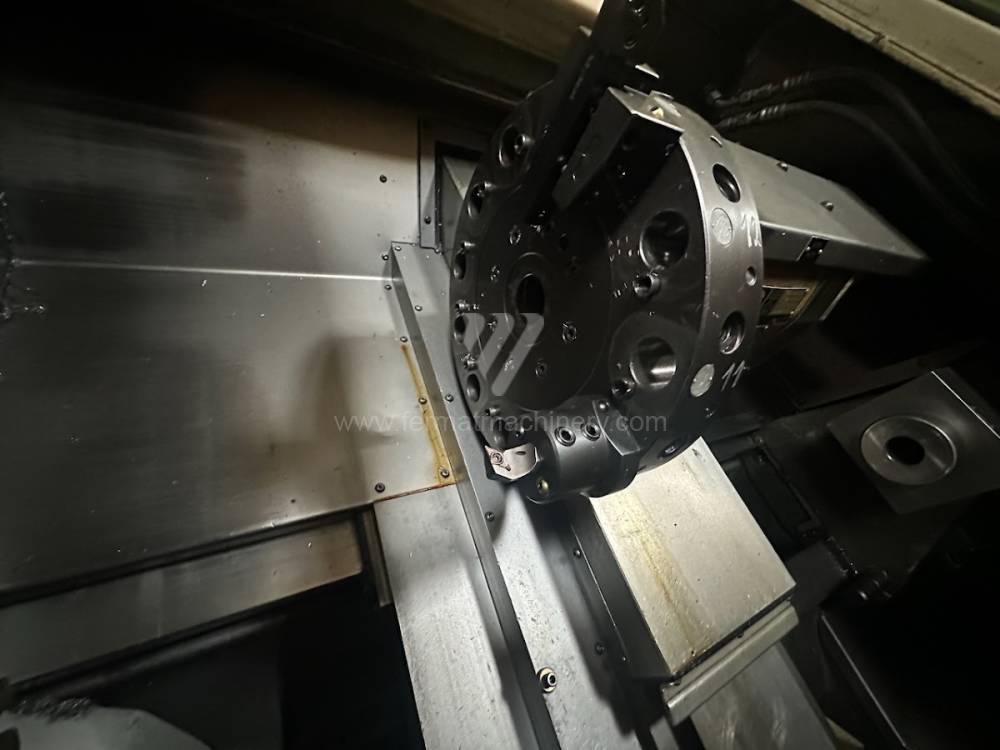

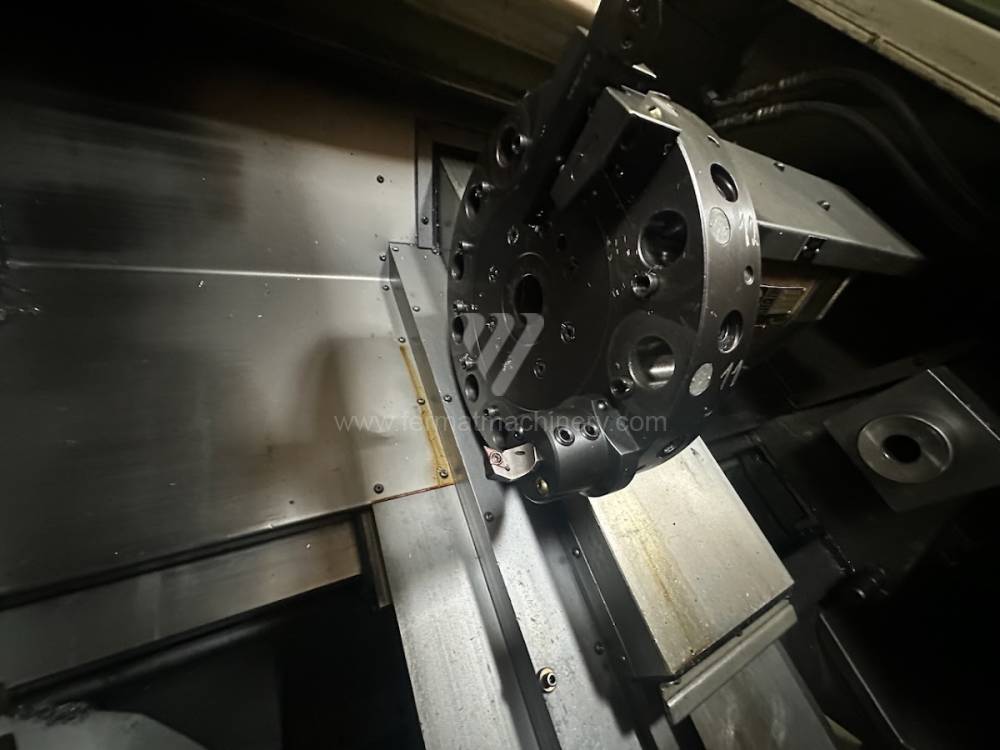

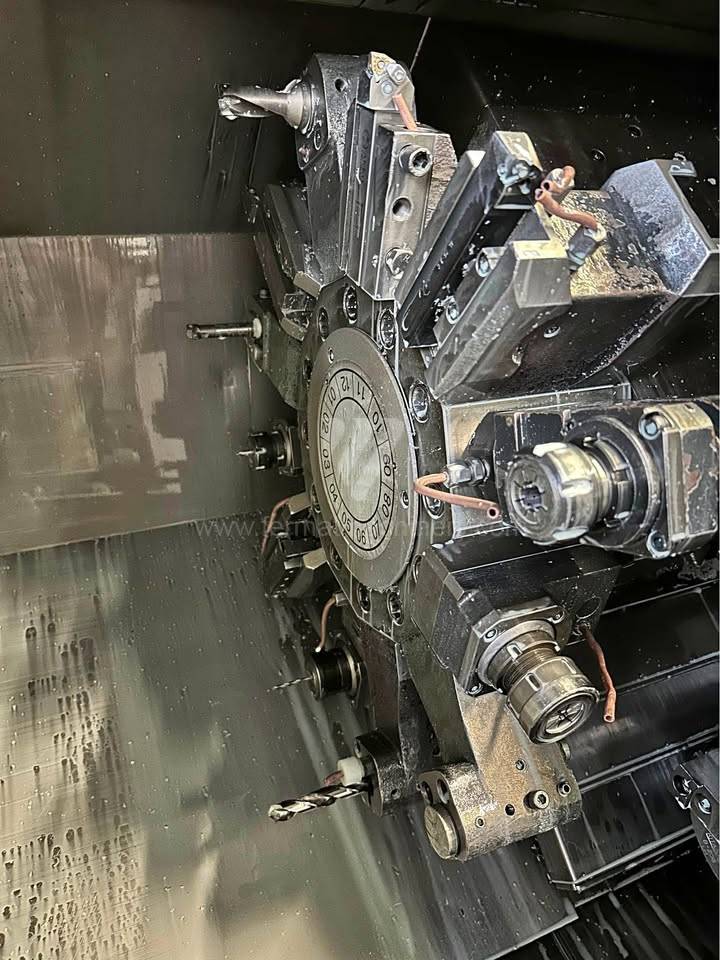

Turret head: YES

Swing over cross slide: 225 mm

YOM:2006

Swing over bed: 860 mm

Distance between centres: 3000 mm

Max. weight of workpiece: kg

Swing over cross slide: 620 mm

Main motor power: 15 kW

Machine weight: 5600 kg

YOM:2000

Control system Mazatrol:

Turn table diameter: 300 mm

Turning lenght: 575 mm

Sloping bed: YES

Y axis: NO

Spindle bore: 50 mm

Swing over bed: 410 mm

Distance between centres: 1000 mm

Max. weight of workpiece: 1000 kg

Swing over cross slide: 225 mm

Spindle speed: 12 - 2000 /min.

Main motor power: 7,5 kW

YOM:2007

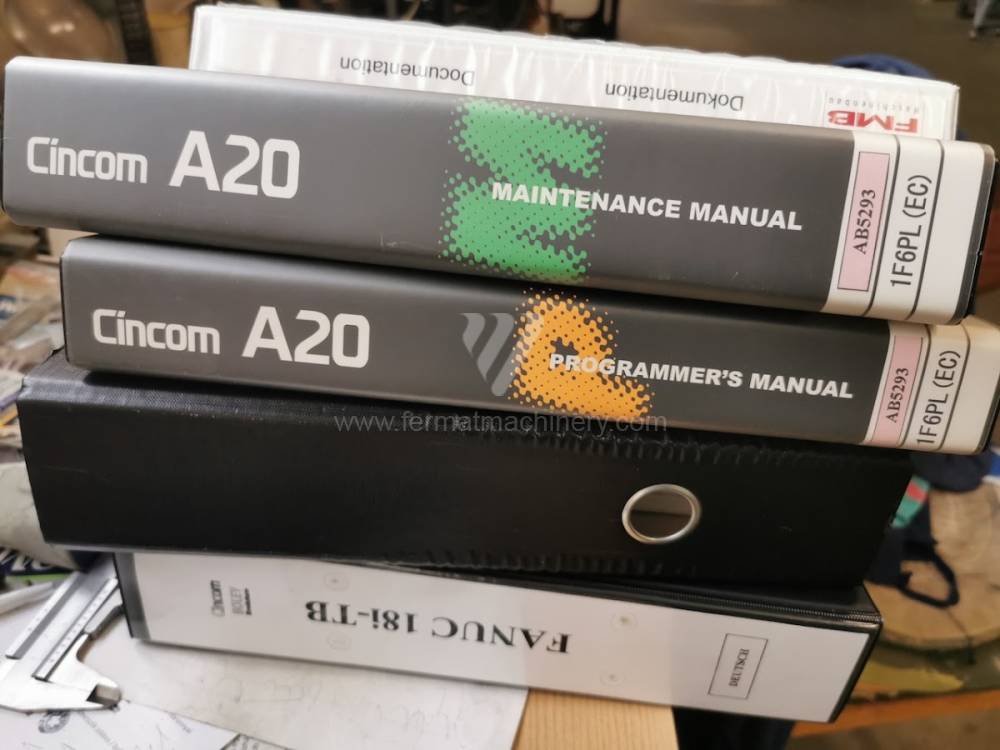

Control system Fanuc: 18i-TB

Turn table diameter: 600 mm

Turning lenght: 1400 mm

Sloping bed: YES

Y axis: YES

Travel Y-axis (lathe): +/- 50 mm

YOM:2017

Turn table diameter: 360 mm

Turning lenght: 1000 mm

Sloping bed: NO

Spindle bore: 52 mm

Turret head: YES

Machine weight: 1930 kg

YOM:2022

Control system Siemens: Sinumerik 840 D

Turn table diameter: 400 mm

Turning lenght: 800 mm

Sloping bed: YES

Spindle bore: 80 mm

Turret head: YES

YOM:2004

Swing over bed: 800 mm

Distance between centres: 8000 mm

Max. weight of workpiece: 3500 kg

Swing over cross slide: 490 mm

Spindle speed: 10 - 1250 /min.

Spindle bore: 105 mm

YOM:2018

Control system OKUMA: OSP-P300LA

Turn table diameter: 580 mm

Turning lenght: 250 mm

Sloping bed: YES

Y axis: YES

Travel Y-axis (lathe): 100 mm

YOM:2008

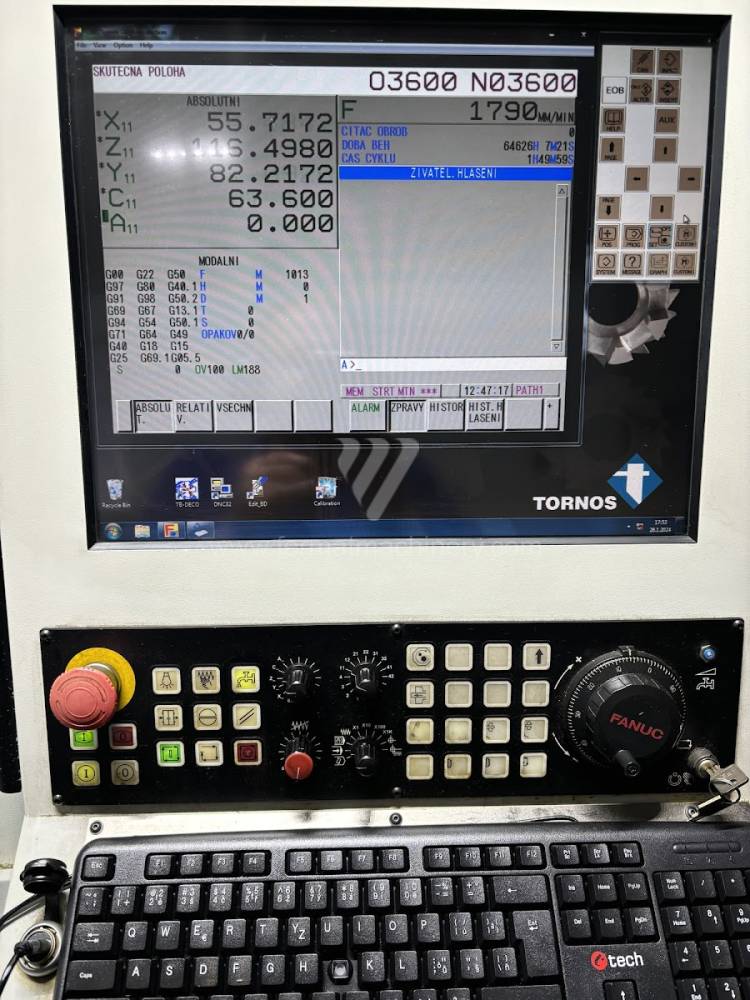

Control system Fanuc: 18i-TB

Turn table diameter: 20 mm

Turning lenght: 165 mm

Sloping bed: NO

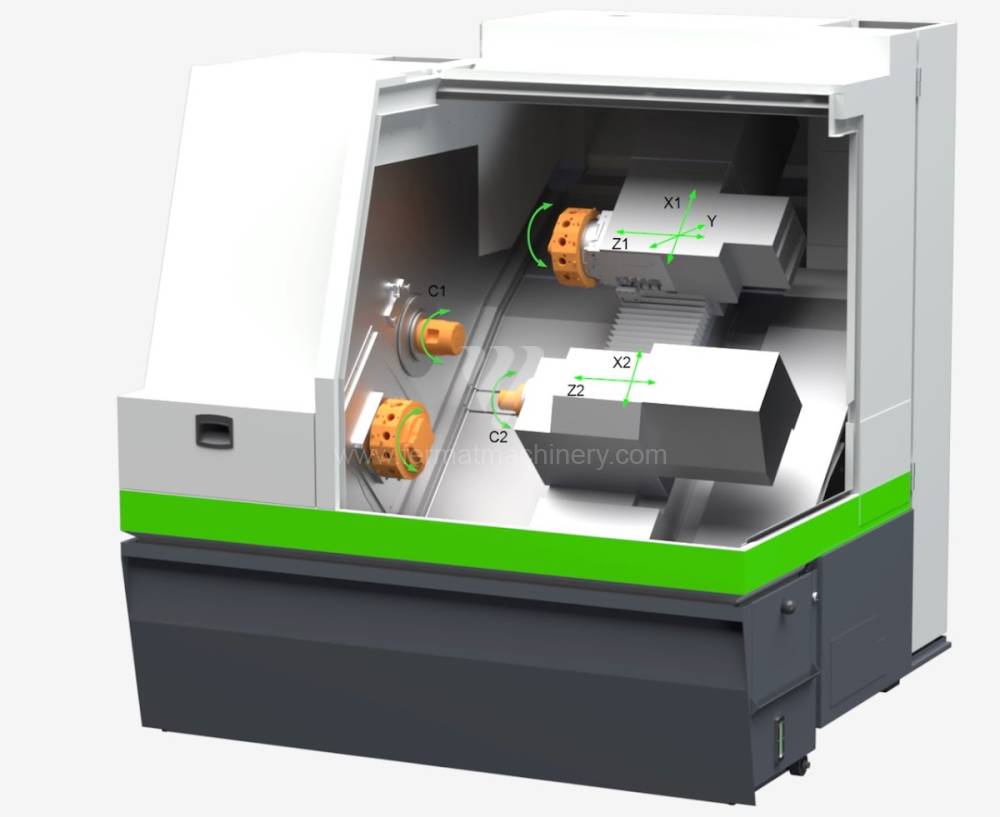

Y axis: YES

Counterspindle: YES

YOM:2002

Control system Siemens: Sinumerik 840 D

Turn table diameter: mm

Turning lenght: mm

Sloping bed: YES

Y axis: YES

Travel Y-axis (lathe): 70 mm

YOM:2018

Max. length of workpiece: 320 mm

Swing over bed: 32 mm

Control system Fanuc: Fanuc 31i

Turn table diameter: 32 mm

Spindle speed: 1 - 6000 /min.

Rapid feed: 32 m/min

YOM:1997

Control system Heidenhain: Manual Plus M

Turn table diameter: 500 mm

Turning lenght: 1500 mm

Sloping bed: NO

Spindle bore: 82 mm

Turret head: NO

YOM:1994

Control system Siemens: Sinumerik 810

Turn table diameter: 1320 mm

Turning lenght: 3000 mm

Sloping bed: NO

Spindle bore: 140 mm

Turret head: NO

Control system Mazatrol: T Plus

Turn table diameter: 230 mm

Turning lenght: 305 mm

Sloping bed: YES

Y axis: NO

Counterspindle:

YOM:2020

Control system Siemens: Sinumerik 828 D BASIC

Turn table diameter: 400 mm

Turning lenght: 320 mm

Sloping bed: NO

Y axis: NO

Counterspindle: NO

YOM:1992

Swing over bed: 630 mm

Distance between centres: 2000 mm

Max. weight of workpiece: 1500 kg

Swing over cross slide: 340 mm

Main motor power: 11 kW

Machine dimensions l x w x h: 4000 x 1400 x 1520 mm

YOM:2013

Control system OKUMA: OSP-P300LA

Turn table diameter: 580 mm

Turning lenght: 150 mm

Sloping bed: YES

Y axis: YES

Travel Y-axis (lathe): 100 mm

YOM:2022

Turning lenght: 510 mm

Turn table diameter: 300 mm

Sloping bed: YES

Turret head: YES

Spindle bore: 65 mm

Swing over bed: 600 mm

YOM:2013

Control system Fanuc: 31i - B5

Turn table diameter: 10 mm

Turning lenght: 100 mm

Sloping bed: YES

Y axis: YES

Counterspindle: YES

YOM:2001

Control system Heidenhain: Manual Plus 4110

Turn table diameter: 500 mm

Turning lenght: 1500 mm

Sloping bed: NO

Spindle bore: 82 mm

Turret head: NO

YOM:2021

Control system Siemens: Sinumerik 808 D

Turn table diameter: 500 mm

Turning lenght: 1500 mm

Sloping bed: NO

Spindle bore: 82 mm

Turret head: YES

YOM:1990

Swing over bed: 400 mm

Distance between centres: 2000 mm

Swing over cross slide: 220 mm

Main motor power: 7,5 kW

Machine dimensions l x w x h: 2580 x 1280 x 1450 mm

YOM:1992

Max. length of workpiece: 205 mm

Swing over bed: 16 mm

Counterspindle: YES

Machine weight: 1700 kg

Bar loader: YES

Driven Tools: YES

YOM:2005

Control system Fanuc: 18i-TB

Turn table diameter: 334 mm

Turning lenght: 510 mm

Sloping bed: YES

Y axis: YES

Counterspindle: YES

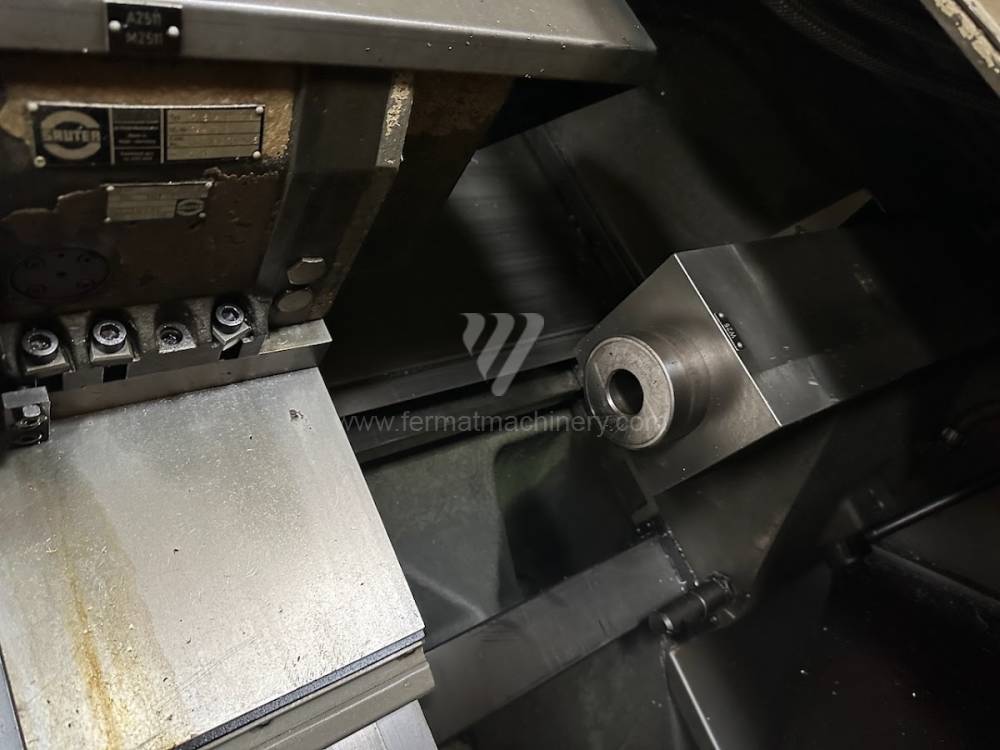

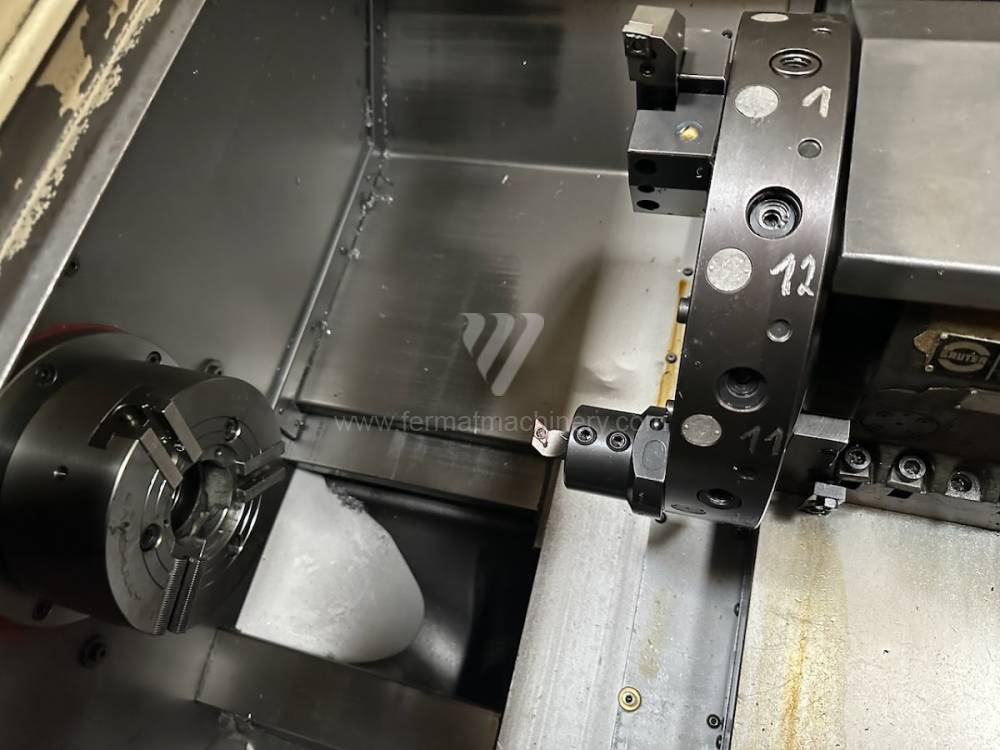

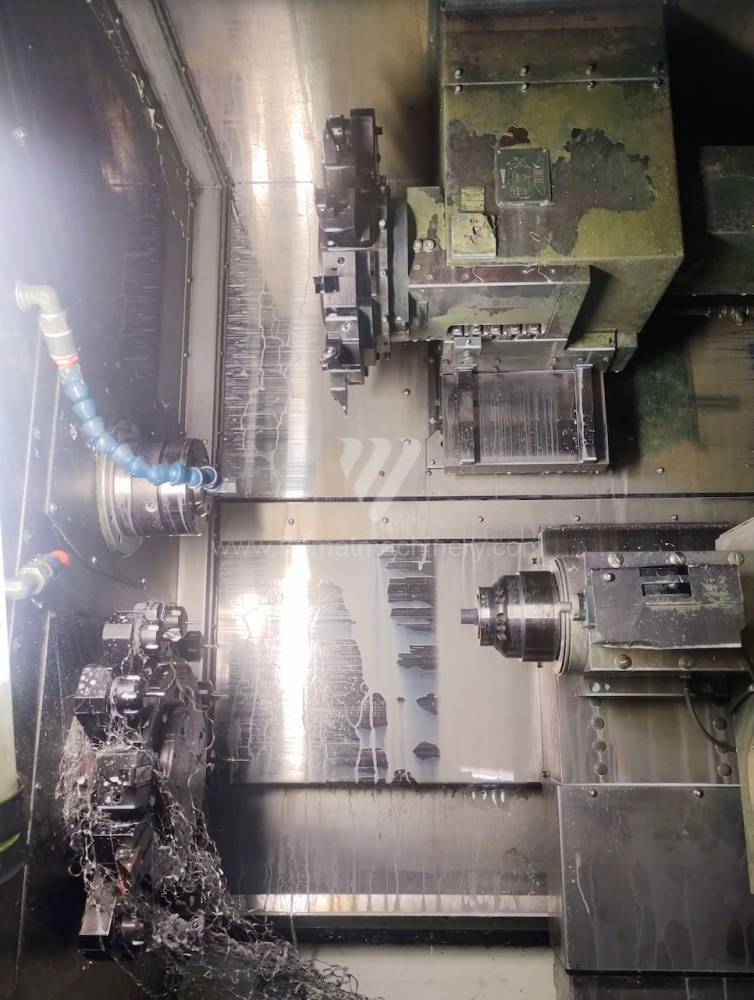

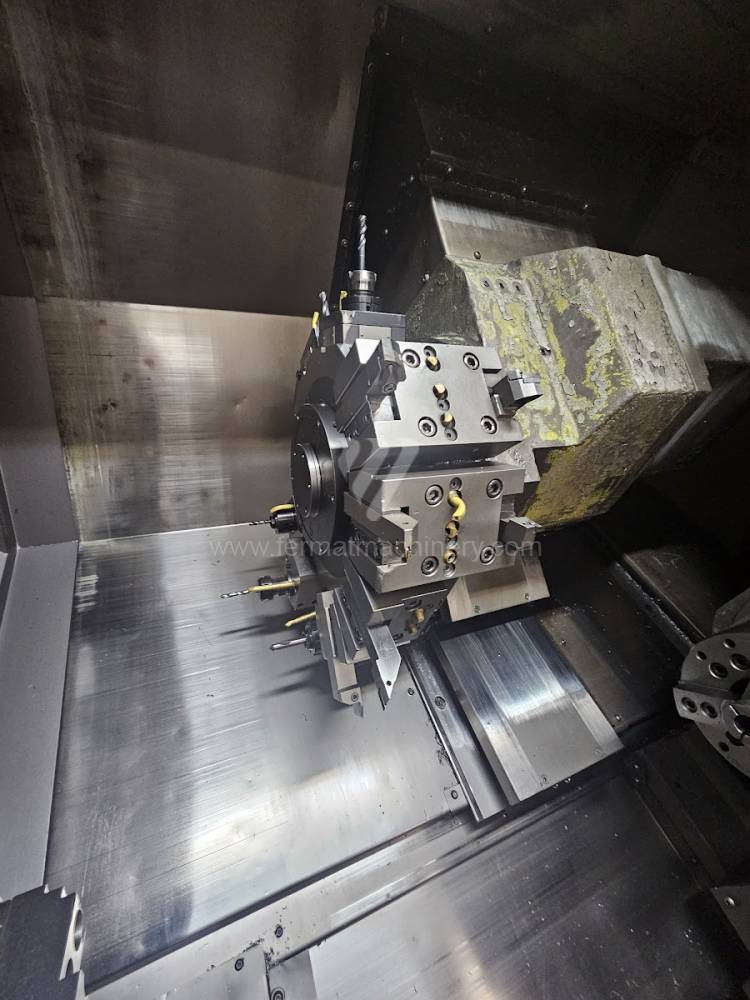

Lathe – is a mechanical device that uses a chip machining to change a shape of the material or component by rotation or cutting into its final product (semi-finished product). Using the lathe, it is possible to produce rotary parts, drill holes, cut external and internal threads.

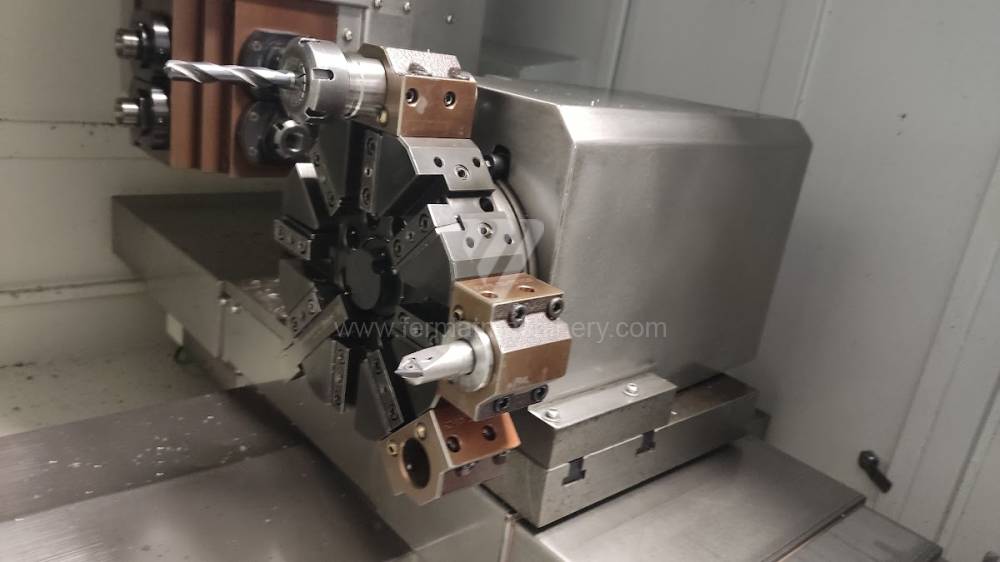

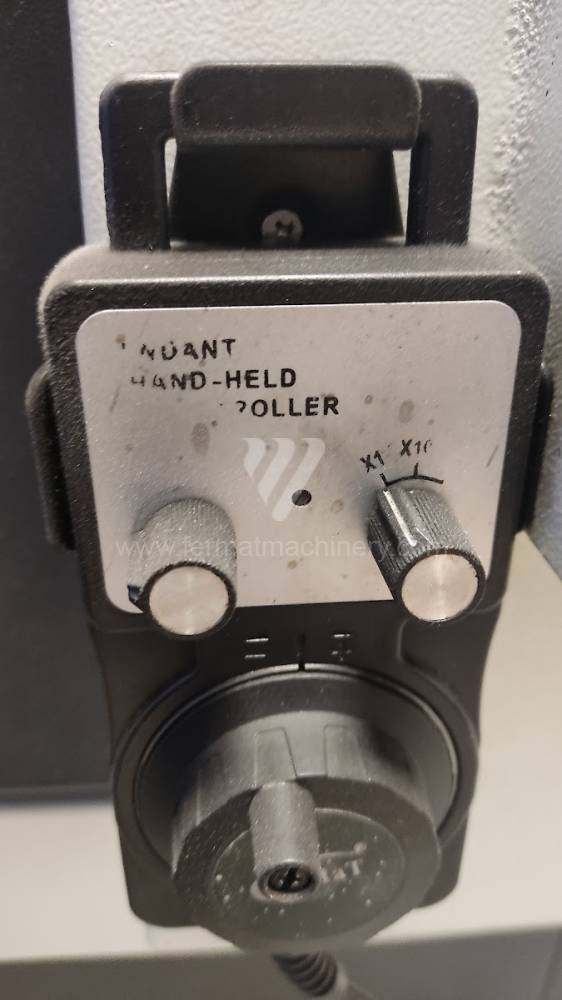

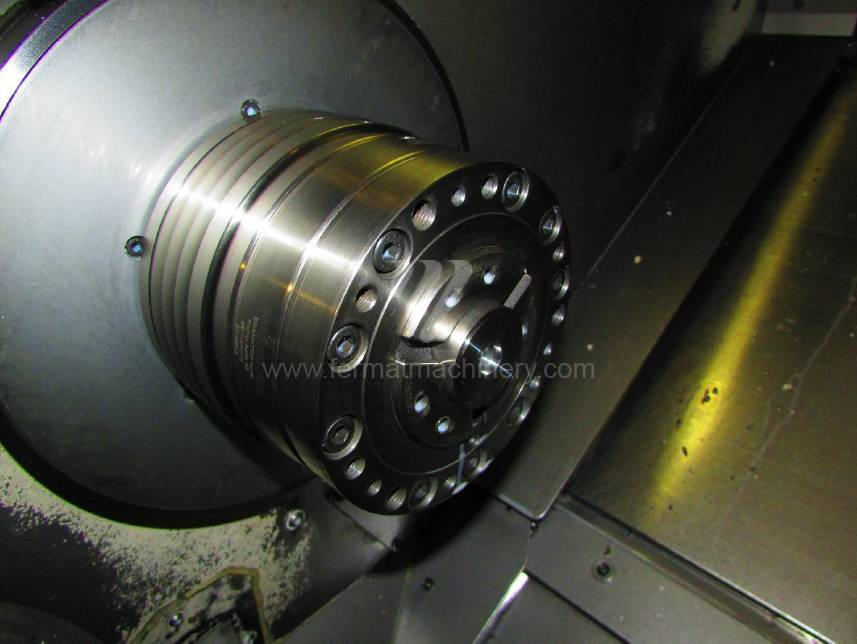

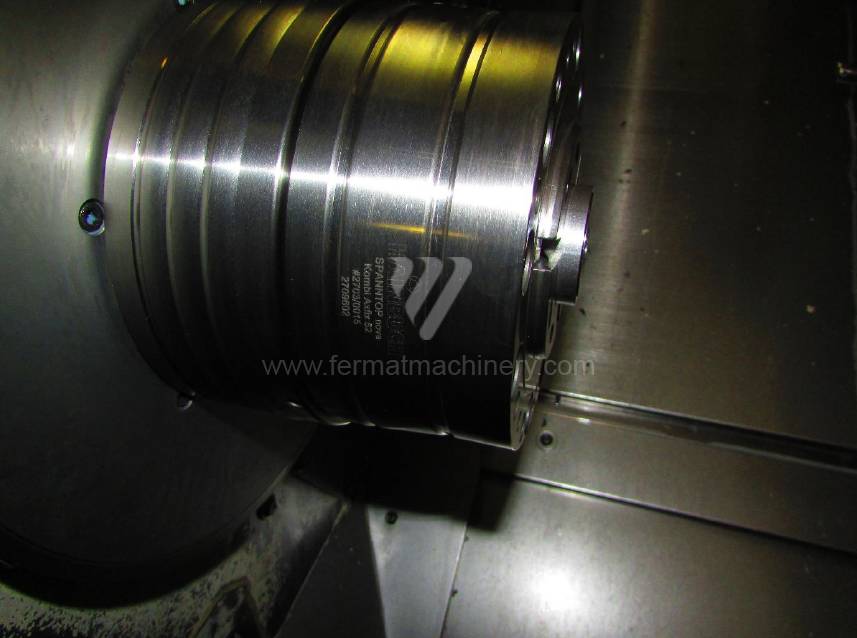

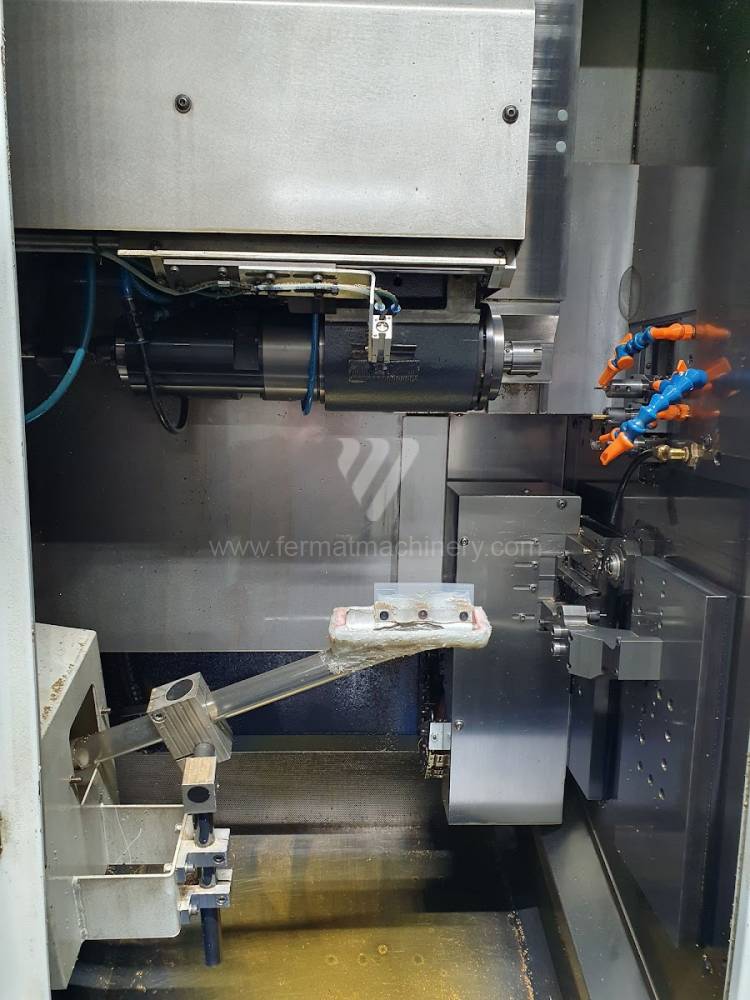

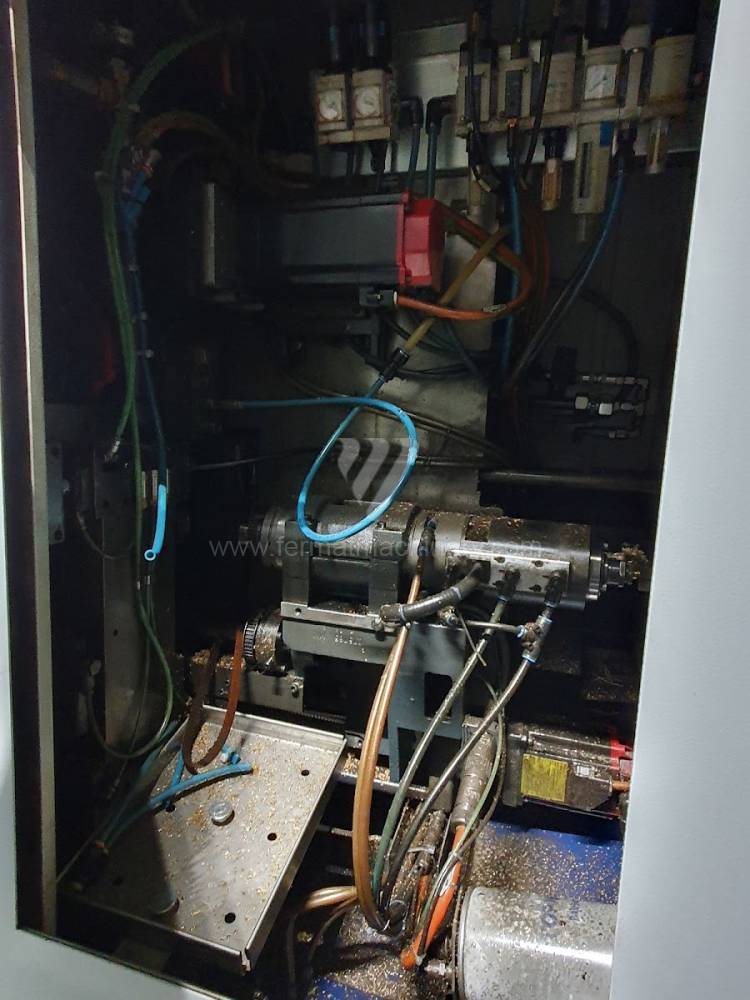

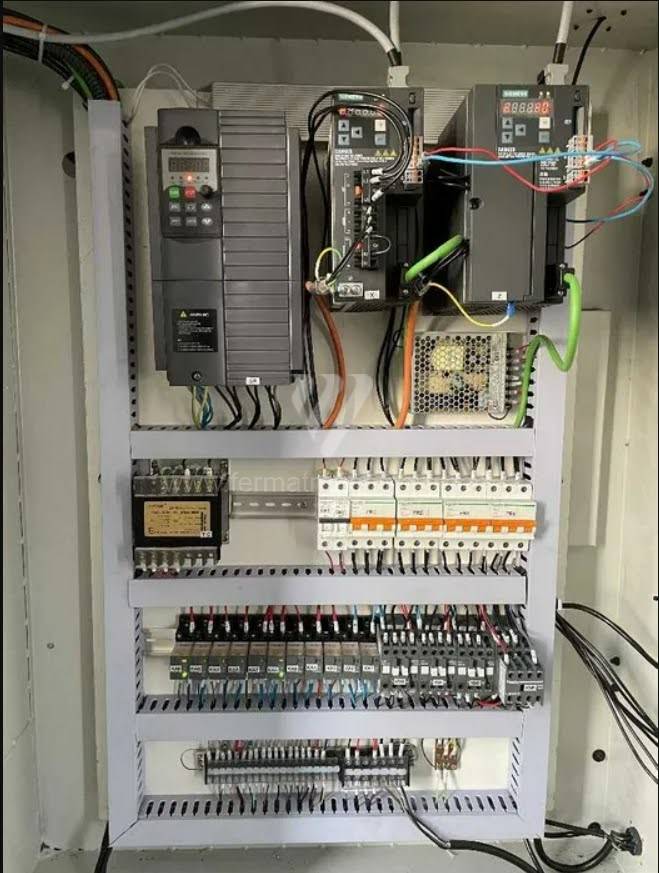

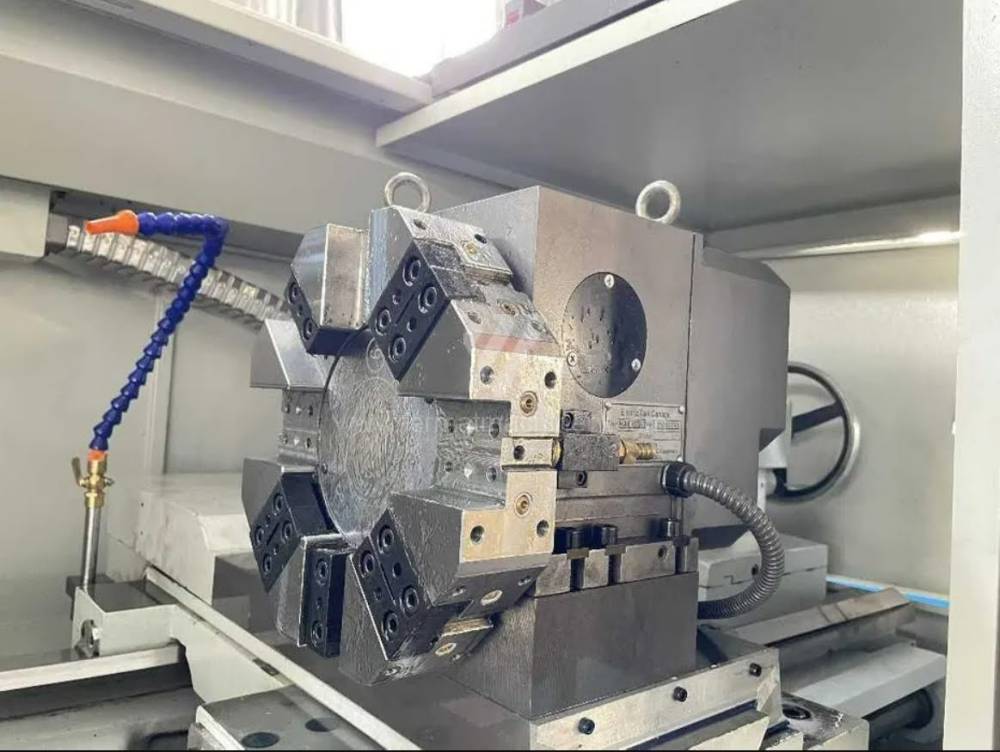

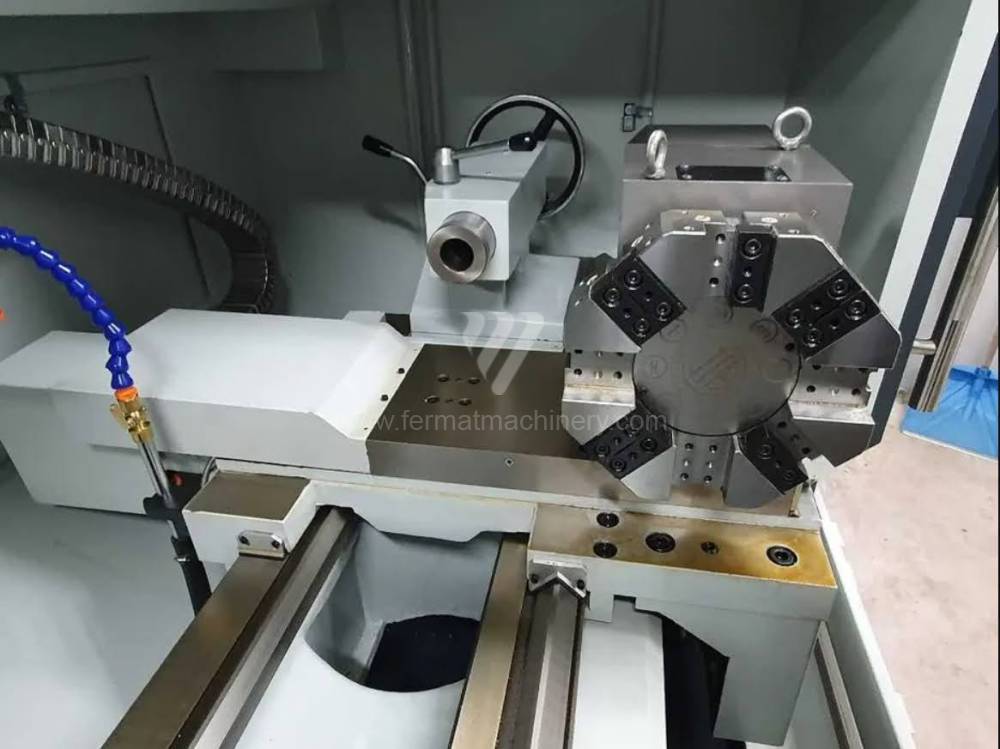

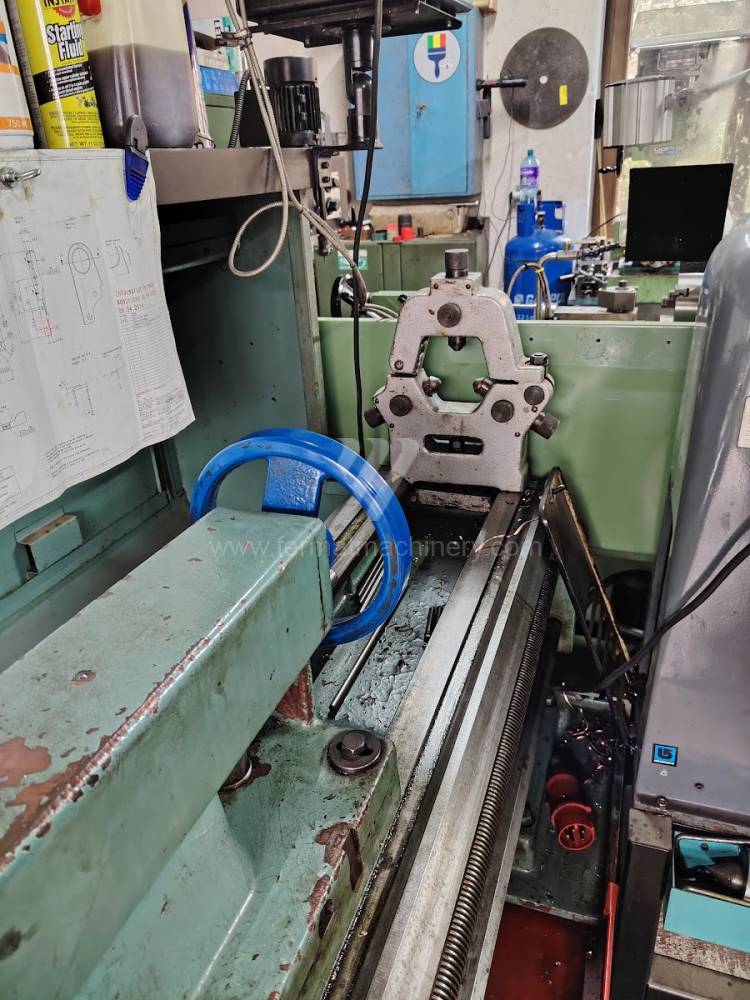

The material (product) is clamped in the chuck. The lathe is produced in several dimensions, according to turntable diameter or turning length. Other equipment can be a revolver head, milling head, counter spindle, tailstock, chip conveyor (for extracting metal chips), cooling system (during turning a lot of heat is generated, which must be cooled. The cooling can be internal or external and according to its strength is expressed in bars).In case of CNC lathes. For numerically controlled lathes, if the manufacturer does not have its own system, it is possible to choose the system which is commonly used, for example: Fanuc, Siemens, Heidenhain or Fagor.

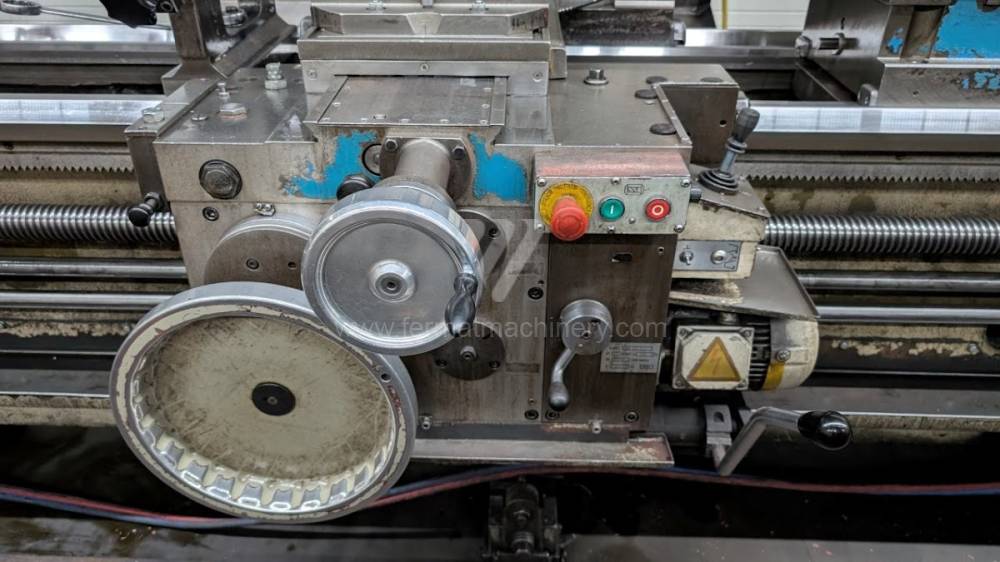

The regular lathe consists of following parts: beds, spindle, support, tailstock spindle or sliding gearbox.

Clamping part – it is usually formed by a chuck on one side and tailstock on the other, or a chuck and second clamping part by a counter spindle.

Cutting part – formed by a cutting wedge attached to the longitudinal part - the Z axis.

The transverse part (perpendicular to the axis of the spindle) designated as the X-axis, or the automatic tool head, also usually located on the transverse feed on the machine.

The machine can be erupted with a measuring tool probe (automatically or manually foldable).

There are several hundreds manufacturers in the world, among the most popular in Czech republic are: TOS, MAZAK, DOOSAN, ŠKODA, OKUMA, GILDEMEISTER, HAAS, KOVOSVIT, GOODWAY, TAJMAC-ZPS.