Închide

| Denumire produs | Nr. inv. | Producător | An fabricație | Parametri | ||

|---|---|---|---|---|---|---|

|

SN 63 B/3000 |

241153 | TOS Trenčín | Diametru periferic deasupra batiului: 630 mm Distanța dintre vârfuri: 3000 mm Greutatea maximă a piesei de lucru: kg Diametru periferic peste ghidaje: 340 mm Diametrul mandrinei: 315 mm Alezaj ax': 72 mm |

||

|

SU 125/4000 |

251378 | TOS Čelákovice | Diametru periferic deasupra batiului: 1250 mm Distanța dintre vârfuri: 4000 mm Greutatea maximă a piesei de lucru: 6000 kg Viteza axului: 0 - 450 /min. Dimensiunile mașinii L x l x Î: 7900 x 1970 x 1480 mm Geutatea mașinii: 9500 kg |

||

|

SN 63 B/2000 |

241617 | TOS Trenčín | 1994 | Diametru periferic deasupra batiului: 630 mm Distanța dintre vârfuri: 2000 mm Greutatea maximă a piesei de lucru: kg Diametru periferic peste ghidaje: 340 mm Puterea motorului principal: 7.5 kW Dimensiunile mașinii L x l x Î: 4000 x 1400 x 1520 mm |

|

|

CTX 210 V1 |

241719 | Gildemeister | 2004 | Sistem de control Fanuc: Diametrul de strunjire: 380 mm Lungimea de strunjire: mm Deplasarea pe axa X: 151 mm Deplasarea pe axa Z: 339 mm Diametru periferic peste ghidaje: 290 mm |

|

|

SN 71 B/2000 |

241614 | TOS Trenčín | 1979 | Diametru periferic deasupra batiului: 710 mm Distanța dintre vârfuri: 2000 mm Greutatea maximă a piesei de lucru: 850 kg Diametru periferic peste ghidaje: 420 mm Viteza axului: 10 - 1000 /min. Puterea motorului principal: 7,5 kW |

|

|

CTX 210 V3 |

241721 | Gildemeister | 2006 | Sistem de control Fanuc: Fanuc 32i Diametrul de strunjire: 290 mm Lungimea de strunjire: 339 mm Batiu inclinat/oblic: da Axa Y: nu Contra-ax: nu |

|

|

SN 71 B/4000 |

241564 | TOS Trenčín | 1978 | Diametru periferic deasupra batiului: 710 mm Lungimea maximă a piesei de lucru: 4000 mm |

|

|

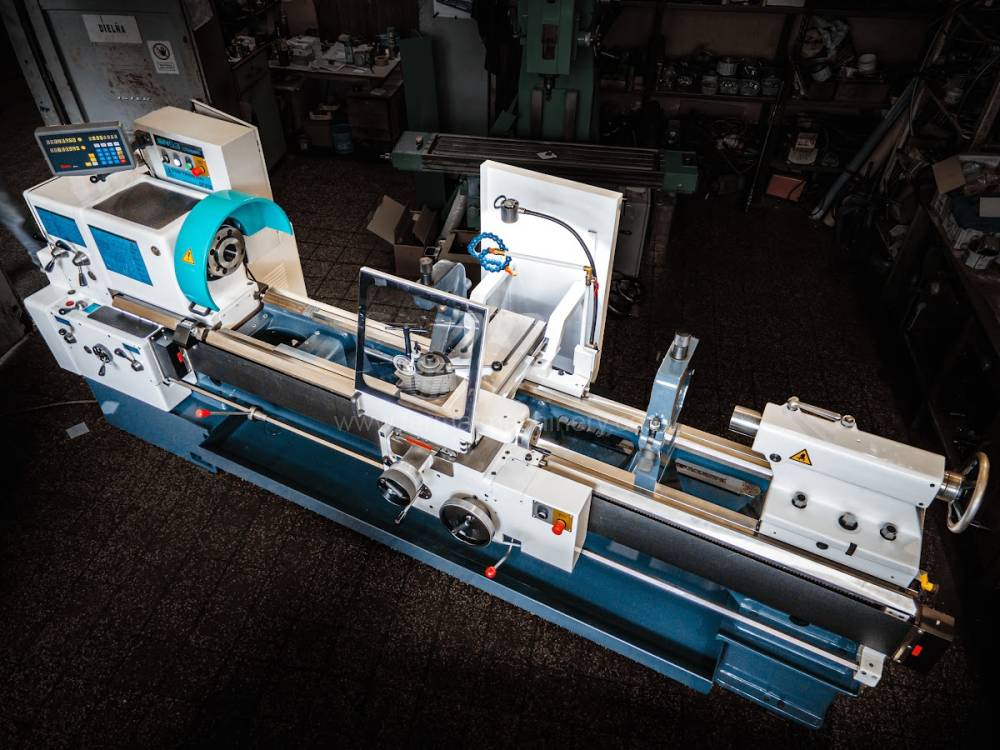

SN 50 C/2000 |

251283 | Trens | 2005 | Diametru periferic deasupra batiului: 500 mm Distanța dintre vârfuri: 2000 mm Greutatea maximă a piesei de lucru: 300 kg Diametru periferic peste ghidaje: 270 mm Alezaj ax': 52 mm Viteza axului: 22 - 2000 /min. |

|

|

SUS 80/2750 |

251379 | TOS Čelákovice | Diametru periferic deasupra batiului: 840 mm Distanța dintre vârfuri: 2750 mm Greutatea maximă a piesei de lucru: 6000 kg Diametru periferic peste ghidaje: 530 mm Alezaj ax': 82 mm Viteza axului: 7 - 900 /min. |

||

|

CTX 310 V3 CNC |

241273 | Gildemeister | 2005 | Sistem de control Siemens: Sinumerik 840 D Diametrul de strunjire: 365 mm Lungimea de strunjire: 450 mm Batiu inclinat/oblic: da Axa Y: nu Contra-ax: nu |

|

|

SP 180 |

251589 | KOVOSVIT MAS, a.s. | 2005 | Sistem de control Siemens: Sinumerik 840 D Diametrul de strunjire: 180 mm Lungimea de strunjire: 400 mm Batiu inclinat/oblic: da Alezaj ax': 63 mm Capul revolver: da |

|

|

SN 71 C/2000 |

251281 | Trens | 2006 | Diametru periferic deasupra batiului: 710 mm Distanța dintre vârfuri: 2000 mm Greutatea maximă a piesei de lucru: 850 kg Diametru periferic peste ghidaje: 420 mm Alezaj ax': 73,5 mm Viteza axului: 10 - 1000 /min. |

|

|

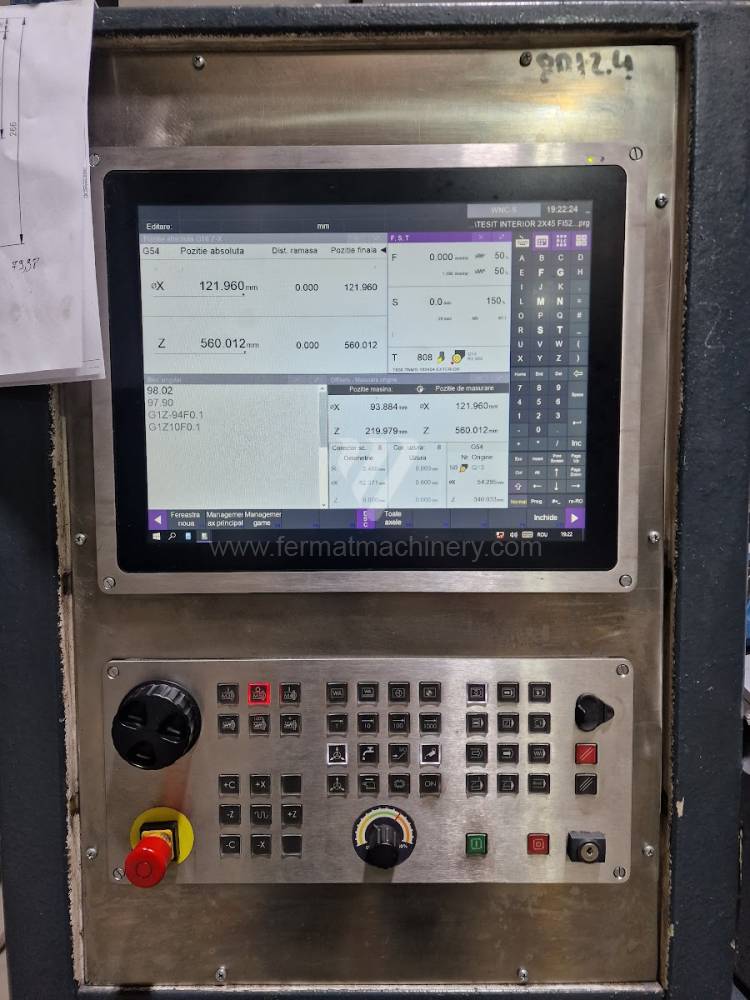

WNC 300 S-560 |

251499 | VOEST - ALPINE | Sistem de control NCT: Lungimea de strunjire: 500 mm Diametru periferic deasupra batiului: 470 mm Diametru periferic peste ghidaje: 345 mm Alezaj ax': 77 mm Viteza axului: 0 - 3000 /min. |

||

|

ZL-250MC/600 |

201166 | MORI SEIKI | 1999 | Diametrul maxim de strunjire: 390 mm Diametru periferic deasupra batiului: 700 mm Distanța dintre vârfuri: 725 mm Viteza axului: 35 - 3500 /min. Alezaj ax': 86 mm Deplasarea pe axa X: 1:238/2:173 mm |

|

|

ALPHA 1350 XT |

251960 | Colchester | 2008 | Sistem de control Fanuc: Diametrul de strunjire: 350 mm Lungimea de strunjire: 650 mm Batiu inclinat/oblic: nu Alezaj ax': 42 mm Capul revolver: nu |

|

|

FTC 350 LMC |

261010 | FEELER | 2020 | Sistem de control Fanuc: 0i-TF Diametrul de strunjire: 235 mm Lungimea de strunjire: 600 mm Batiu inclinat/oblic: da Axa Y: nu Contra-ax: nu |

|

|

C 630 BE |

251166 | ZMM Bulgaria | Sistem de control Heidenhain: Diametrul de strunjire: 630 mm Lungimea de strunjire: 1000 mm Batiu inclinat/oblic: nu Alezaj ax': 103 mm Capul revolver: da |

||

|

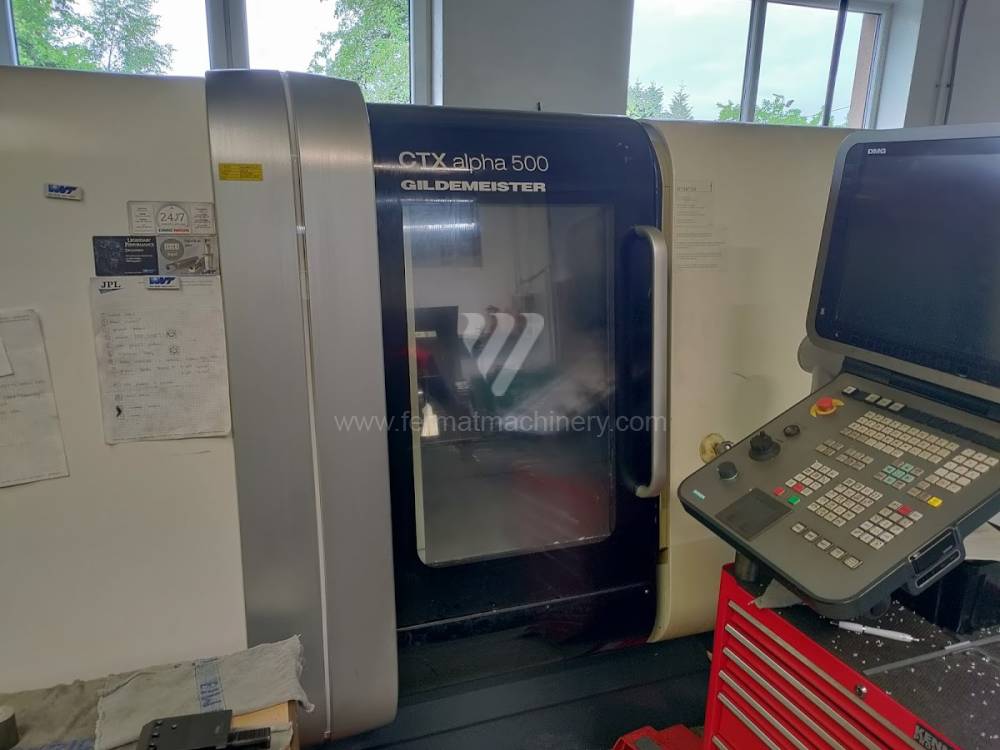

CTX alpha 500 |

231507 | DMG MORI | 2008 | Sistem de control Siemens: Sinumerik 840D Sl Diametrul de strunjire: 500 mm Lungimea de strunjire: 780 mm Batiu inclinat/oblic: da Axa Y: da Deplasarea pe axa Y (Strunguri): 190 mm |

|

|

SUI 500 COMBI |

241550 | TOS Trenčín | 1999 | Sistem de control Siemens: 810 D Diametrul de strunjire: 500 mm Lungimea de strunjire: 1500 mm Batiu inclinat/oblic: nu Alezaj ax': 71 mm Capul revolver: |

|

|

Puma 2600Y |

242082 | Doosan | 2015 | Sistem de control Fanuc: Series 0i Diametrul de strunjire: 376 mm Lungimea de strunjire: 760 mm Batiu inclinat/oblic: da Axa Y: da Contra-ax: nu |

|

|

SUS 63/2000 |

251294 | TOS Čelákovice | 1990 | Diametru periferic deasupra batiului: 630 mm Distanța dintre vârfuri: 2000 mm Greutatea maximă a piesei de lucru: 2000 kg Diametru periferic peste ghidaje: 390 mm Alezaj ax': 81 mm Viteza axului: 9 - /min. |

|

|

DECO 13a |

251718 | Tornos Bechler | 2008 | Lungimea maximă a piesei de lucru: 184 mm Diametru periferic deasupra batiului: mm |

|

|

QUICK TURN NEXUS 200-II |

251438 | MAZAK | 2007 | Sistem de control Mazatrol: MATRIX NEXUS Diametrul de strunjire: 350 mm Lungimea de strunjire: 1021 mm Batiu inclinat/oblic: da Alezaj ax': ano mm Capul revolver: nu |

|

|

SV 18 RA/750 |

241713 | TOS Trenčín | Diametru periferic deasupra batiului: 380 mm Distanța dintre vârfuri: 750 mm Greutatea maximă a piesei de lucru: 300 kg Diametru periferic peste ghidaje: 215 mm Viteza axului: 14 - 2800 /min. Puterea motorului principal: 6 kW |

||

|

GS 51 |

252008 | Hardinge Inc. | 2010 | Sistem de control Fanuc: 0i - TD Diametrul de strunjire: 356 mm Lungimea de strunjire: 610 mm Batiu inclinat/oblic: da Alezaj ax': 52 mm Capul revolver: da |

Lathe – is a mechanical device that uses a chip machining to change a shape of the material or component by rotation or cutting into its final product (semi-finished product). Using the lathe, it is possible to produce rotary parts, drill holes, cut external and internal threads.

The material (product) is clamped in the chuck. The lathe is produced in several dimensions, according to turntable diameter or turning length. Other equipment can be a revolver head, milling head, counter spindle, tailstock, chip conveyor (for extracting metal chips), cooling system (during turning a lot of heat is generated, which must be cooled. The cooling can be internal or external and according to its strength is expressed in bars).In case of CNC lathes. For numerically controlled lathes, if the manufacturer does not have its own system, it is possible to choose the system which is commonly used, for example: Fanuc, Siemens, Heidenhain or Fagor.

The regular lathe consists of following parts: beds, spindle, support, tailstock spindle or sliding gearbox.

Clamping part – it is usually formed by a chuck on one side and tailstock on the other, or a chuck and second clamping part by a counter spindle.

Cutting part – formed by a cutting wedge attached to the longitudinal part - the Z axis.

The transverse part (perpendicular to the axis of the spindle) designated as the X-axis, or the automatic tool head, also usually located on the transverse feed on the machine.

The machine can be erupted with a measuring tool probe (automatically or manually foldable).

There are several hundreds manufacturers in the world, among the most popular in Czech republic are: TOS, MAZAK, DOOSAN, ŠKODA, OKUMA, GILDEMEISTER, HAAS, KOVOSVIT, GOODWAY, TAJMAC-ZPS.