Vicino

| Nome del prodotto | Nr. di inventario | Produttore | Anno di fabbricazione | Parametri | ||

|---|---|---|---|---|---|---|

|

GENOS L300M |

231361 | Okuma Corporation | 2014 | Sistema di controllo OKUMA: OSP-P300LA-e Diametro di rotazione: 300 mm Lunghezza di rotazione: 450 mm Alloggiamento trasversale: Sì Asse Y: No Contromandrino: No |

|

|

GLS- 200Y |

252017 | Goodway | 2020 | Sistema di controllo Fanuc: 0i-TF Diametro di rotazione: 280 mm Lunghezza di rotazione: 710 mm Alloggiamento trasversale: Sì Asse Y: Sì Contromandrino: No |

|

|

SV 18 RA |

241685 | TOS Trenčín | 1983 | Diametro circolare sopra l'alloggiamento: 380 mm Distanza tra i punti: 1250 mm Peso max. del pezzo lavorato: 300 kg Dimensioni lungh. x largh. x alt.: 2500x950 mm Peso della macchina: 1800 kg |

|

|

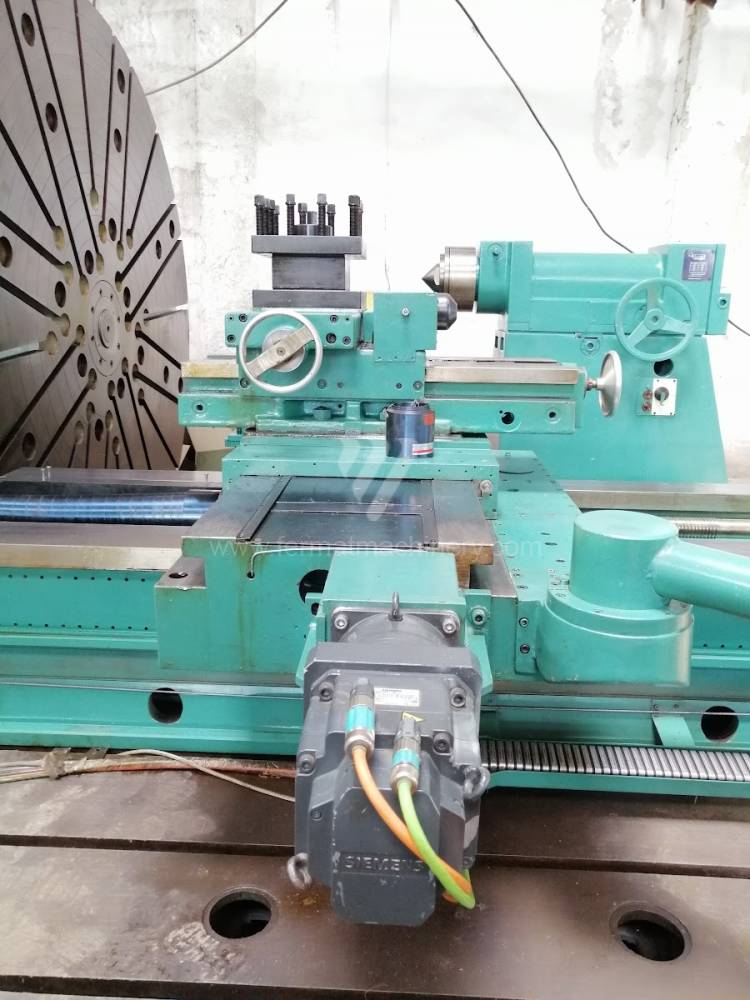

SUS 80 |

251657 | TOS Čelákovice | Diametro circolare sopra l'alloggiamento: 840 mm Distanza tra i punti: 3500 mm Peso max. del pezzo lavorato: kg Peso della macchina: 7200 kg Dimensioni lungh. x largh. x alt.: 5800x1750x1400 mm Foratura mandrino: 82 mm |

||

|

TR 90/4000 |

251055 | Poreba | 1954 | Diametro circolare sopra l'alloggiamento: 900 mm Distanza tra i punti: 4000 mm Peso max. del pezzo lavorato: kg |

|

|

UT-300L |

251905 | ACCUWAY | 2011 | Sistema di controllo Fanuc: 0i - TD Diametro di rotazione: 500 mm Lunghezza di rotazione: 1090 mm Alloggiamento trasversale: Sì Asse Y: No Contromandrino: No |

|

|

ST-30 Y |

231845 | Haas Automation | 2022 | Sistema di controllo Haas: Diametro di rotazione: 457 mm Lunghezza di rotazione: 584 mm Alloggiamento trasversale: Sì Asse Y: Sì Spostamento asse Y (Tornio): +-51 mm |

|

|

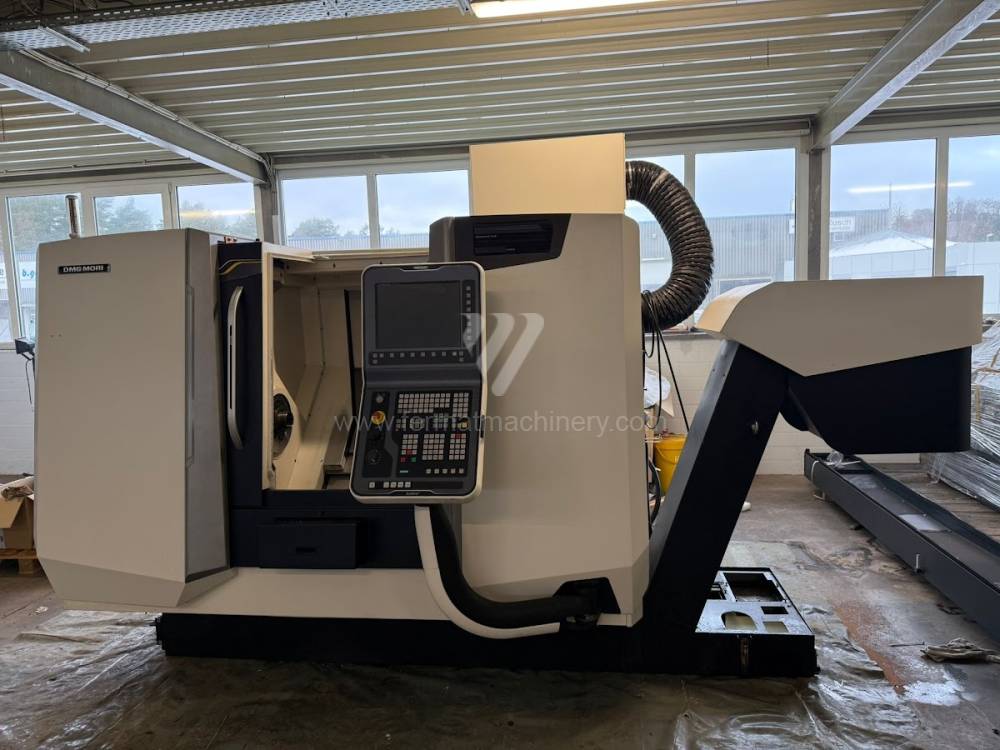

EcoTurn 450 V3 |

261001 | DMG MORI | 2015 | Sistema di controllo Siemens: Sinumerik 840 D Diametro di rotazione: 400 mm Lunghezza di rotazione: 800 mm Alloggiamento trasversale: Sì Asse Y: No Contromandrino: No |

|

|

ALPHA 1400 XT |

251898 | Colchester | 2007 | Sistema di controllo Fanuc: Diametro di rotazione: 400 mm Lunghezza di rotazione: 1250 mm Alloggiamento trasversale: No Foratura mandrino: 55 mm Torretta a revolver: No |

|

|

QT Nexus 350 II |

261093 | MAZAK | 2008 | Sistema di controllo Mazatrol: MATRIX 2 Diametro di rotazione: 420 mm Lunghezza di rotazione: 1200 mm Alloggiamento trasversale: Sì Foratura mandrino: 102 mm Torretta a revolver: Sì |

|

|

Masturn MT 50/1500 |

252015 | KOVOSVIT MAS, a.s. | 2000 | Sistema di controllo Heidenhain: Manual Plus 4110 Diametro di rotazione: 500 mm Lunghezza di rotazione: 1500 mm Alloggiamento trasversale: No Foratura mandrino: 82 mm Torretta a revolver: No |

|

|

NEF 600 |

261107 | DMG | 2011 | Sistema di controllo Siemens: Sinumerik 840 D Diametro di rotazione: 600 mm Lunghezza di rotazione: 1200 mm Alloggiamento trasversale: Sì Foratura mandrino: 90 mm Torretta a revolver: Sì |

|

|

Mini 88 |

251885 | PO LY GIM | 2015 | Sistema di controllo Mitsubishi: Diametro di rotazione: 60 mm Lunghezza di rotazione: 120 mm Alloggiamento trasversale: No Foratura mandrino: 25 mm Torretta a revolver: No |

|

|

SL-30TBHE |

241694 | Haas Automation | 2008 | Sistema di controllo Haas: Diametro di rotazione: 760 mm Lunghezza di rotazione: 860 mm Alloggiamento trasversale: Sì Asse Y: No Contromandrino: No |

|

|

DP 4000 CNC |

241069 | NILES-SIMMONS Industrieanlagen GmbH | Sistema di controllo Siemens: 802 D si Diametro di rotazione: 4000 mm Lunghezza di rotazione: 6000 mm Alloggiamento trasversale: No Foratura mandrino: mm Torretta a revolver: No |

||

|

SN 50 C/1500 |

241775 | TOS Trenčín | 2002 | Diametro circolare sopra l'alloggiamento: 500 mm Distanza tra i punti: 1500 mm Peso max. del pezzo lavorato: kg Diametro circolare sopra supporto: 220 mm Potenza del motore elettrico principale: 5,5 kW Peso della macchina: 1750 kg |

|

|

SN 63 B/1500 |

251658 | TOS Trenčín | 1986 | Diametro circolare sopra l'alloggiamento: 630 mm Distanza tra i punti: 1500 mm Peso max. del pezzo lavorato: kg Diametro circolare sopra supporto: 340 mm Potenza del motore elettrico principale: 7,5 kW Dimensioni lungh. x largh. x alt.: 4000 x 1400 mm |

|

|

NLX 2500/700 SY |

251965 | DMG MORI | 2014 | Sistema di controllo MORI SEIKI: M730BM Diametro di rotazione: 356 mm Lunghezza di rotazione: 705 mm Alloggiamento trasversale: Sì Asse Y: Sì Spostamento asse Y (Tornio): +/-50 mm |

|

|

NEF 400 |

251684 | Gildemeister | 2005 | Sistema di controllo Fanuc: Diametro di rotazione: 400 mm Lunghezza di rotazione: 700 mm Alloggiamento trasversale: Sì Foratura mandrino: 65 mm Torretta a revolver: Sì |

|

|

TCG 125x5000 |

231070 | Poreba | 1984 | Diametro circolare sopra l'alloggiamento: 1250 mm Distanza tra i punti: 5000 mm Peso max. del pezzo lavorato: 30000 kg Lunghezza di rotazione: 5000 mm |

|

|

VTURN - NP20 |

261121 | Victor Machinery Solutions | 2019 | Sistema di controllo Fanuc: 0i-TF Diametro di rotazione: 206 mm Lunghezza di rotazione: 520 mm Alloggiamento trasversale: Sì Foratura mandrino: 52 mm Torretta a revolver: Sì |

|

|

SF 40s CNC |

241762 | Fermat | 2006 | Sistema di controllo Siemens: 802 D si Diametro di rotazione: 340 mm Lunghezza di rotazione: 750 mm Alloggiamento trasversale: No Foratura mandrino: 38 mm Torretta a revolver: Sì |

|

|

Compact A35 CNC |

231369 | KOVOSVIT MAS, a.s. | 2005 | Sistema di controllo Fanuc: 16i - TB Diametro di rotazione: 35 mm Lunghezza di rotazione: 100 mm Alloggiamento trasversale: No Asse Y: Sì Contromandrino: No |

|

|

SUS 63/1250 |

241137 | TOS Čelákovice | Diametro circolare sopra l'alloggiamento: 630 mm Distanza tra i punti: 1250 mm Peso max. del pezzo lavorato: 6000 kg Diametro circolare sopra supporto: 530 mm Potenza del motore elettrico principale: 18 kW Foratura mandrino: 82 mm |

||

|

PUMA 2600 SY |

251159 | Doosan | 2016 | Sistema di controllo Fanuc: i Series Diametro di rotazione: 376 mm Lunghezza di rotazione: 760 mm Alloggiamento trasversale: Sì Asse Y: Sì Spostamento asse Y (Tornio): 104 (+52-52) mm |

Lathe – is a mechanical device that uses a chip machining to change a shape of the material or component by rotation or cutting into its final product (semi-finished product). Using the lathe, it is possible to produce rotary parts, drill holes, cut external and internal threads.

The material (product) is clamped in the chuck. The lathe is produced in several dimensions, according to turntable diameter or turning length. Other equipment can be a revolver head, milling head, counter spindle, tailstock, chip conveyor (for extracting metal chips), cooling system (during turning a lot of heat is generated, which must be cooled. The cooling can be internal or external and according to its strength is expressed in bars).In case of CNC lathes. For numerically controlled lathes, if the manufacturer does not have its own system, it is possible to choose the system which is commonly used, for example: Fanuc, Siemens, Heidenhain or Fagor.

The regular lathe consists of following parts: beds, spindle, support, tailstock spindle or sliding gearbox.

Clamping part – it is usually formed by a chuck on one side and tailstock on the other, or a chuck and second clamping part by a counter spindle.

Cutting part – formed by a cutting wedge attached to the longitudinal part - the Z axis.

The transverse part (perpendicular to the axis of the spindle) designated as the X-axis, or the automatic tool head, also usually located on the transverse feed on the machine.

The machine can be erupted with a measuring tool probe (automatically or manually foldable).

There are several hundreds manufacturers in the world, among the most popular in Czech republic are: TOS, MAZAK, DOOSAN, ŠKODA, OKUMA, GILDEMEISTER, HAAS, KOVOSVIT, GOODWAY, TAJMAC-ZPS.