Close

YOM:1998

Travel X-axis: 520 mm

Travel Y-axis: 370 mm

Travel Z-axis: 300 mm

Axis U: 120 mm

Axis V: 120 mm

Max. weight of workpiece: 650 kg

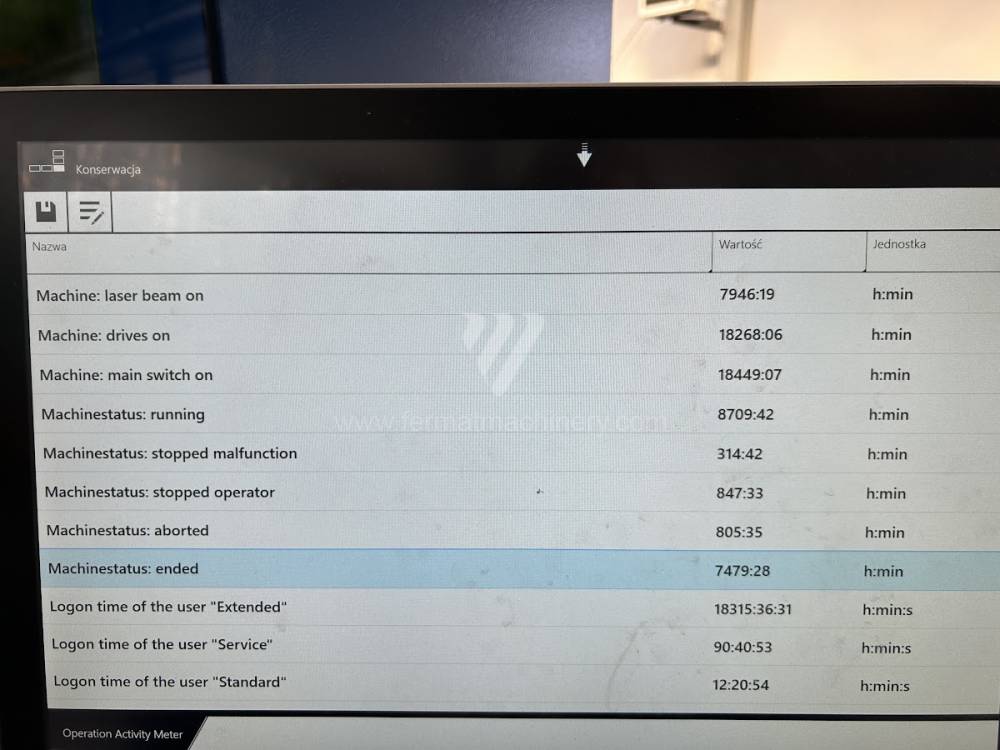

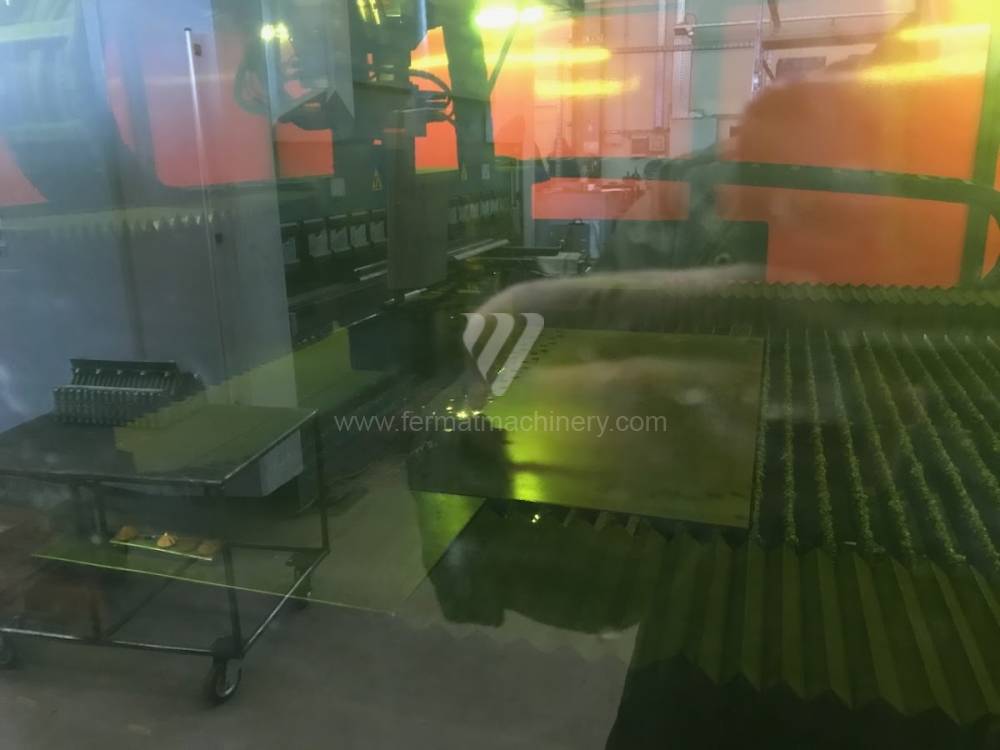

YOM:2012

Max. length of workpiece: 4000 mm

Max. workpiece width: 2000 mm

Max. plate thickness: 20 mm

Power of laser: 3200 W

Fiber:

Machine dimensions l x w x h: 12000x5300x2200 mm

YOM:2015

Max. length of workpiece: 3000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 15 mm

Power of laser: 4000 W

Fiber: YES

Travel X-axis: 3000 mm

YOM:2024

Max. length of workpiece: 1660 mm

Max. workpiece width: 630 mm

Max. thickness cutting material: 20 mm

Type of cutting: Plasma

Machine weight: 7000 kg

Machine dimensions l x w x h: 6000x4000x3000 mm

YOM:2011

Max. length of workpiece: 3050 mm

Max. workpiece width: 1525 mm

Max. plate thickness: 16 mm

Power of laser: 2500 W

Fiber:

Max. load of table: 850 kg

YOM:2023

Travel X-axis: 400 mm

Travel Y-axis: 300 mm

Travel Z-axis: 250 mm

Axis U: 150 mm

Axis V: 150 mm

Max. load of table: 500 kg

YOM:2002

Max. length of workpiece: 3000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 12 mm

Power of laser: 2000 W

Fiber: NO

Total input: 71 kVA

YOM:2023

Max. length of workpiece: mm

Max. workpiece width: mm

Max. thickness cutting material: mm

Type of cutting:

YOM:2001

Max. length of workpiece: 3000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 25 mm

Power of laser: 4400 W

Fiber: NO

Travel X-axis: 3048 mm

YOM:2022

Max. length of workpiece: 3000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 20 mm

Power of laser: 8000 W

Fiber: NO

Max. weight of workpiece: 900 kg

YOM:2016

Max. length of workpiece: 4000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 12 mm

Power of laser: 2000 W

Fiber: YES

Total input: 7 kVA

YOM:2013

Max. length of workpiece: 3000 mm

Max. workpiece width: 1500 mm

Max. plate thickness: 12 mm

Power of laser: 2000 W

Fiber: YES

Travel X-axis: 3050 mm

YOM:2024

Max. diameter of the cut material: 420 mm

Main motor power: 3 kW

Machine weight: 1100 kg

Machine dimensions l x w x h: 3060x1350x1700 mm

Max. length of workpiece: 6000 mm

Max. workpiece width: 3000 mm

Max. thickness cutting material: mm

Type of cutting: Plasma

Plate dimension: 4000x2000 mm

In the category of cutting equipment, we present the most modern machines for planar and shaped division of ferrous and non-ferrous materials.

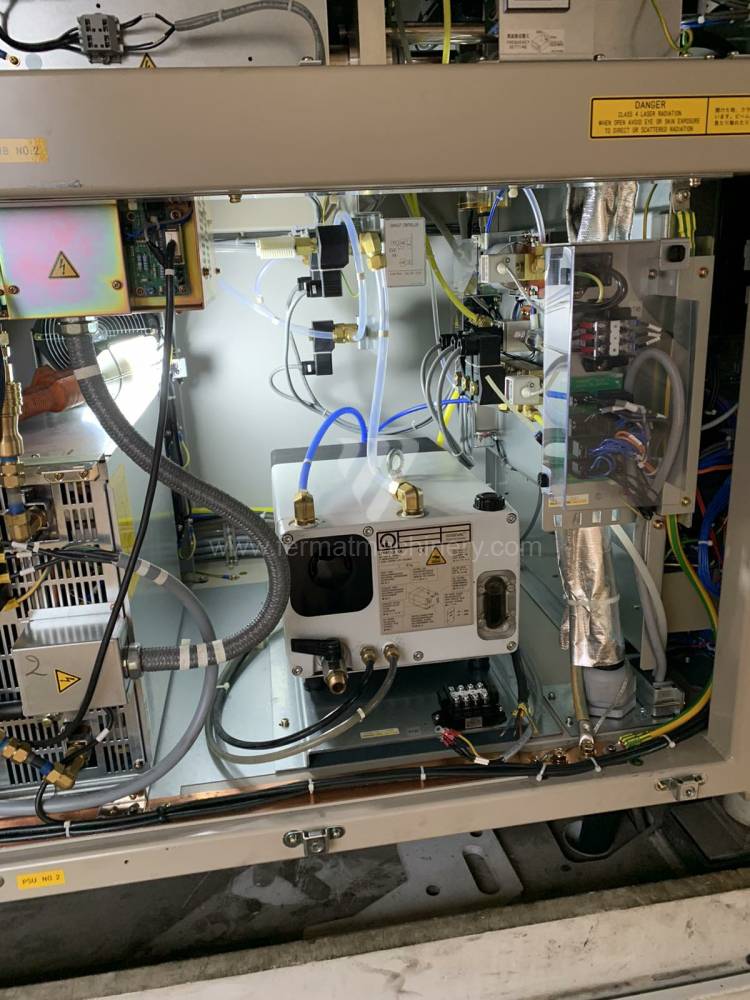

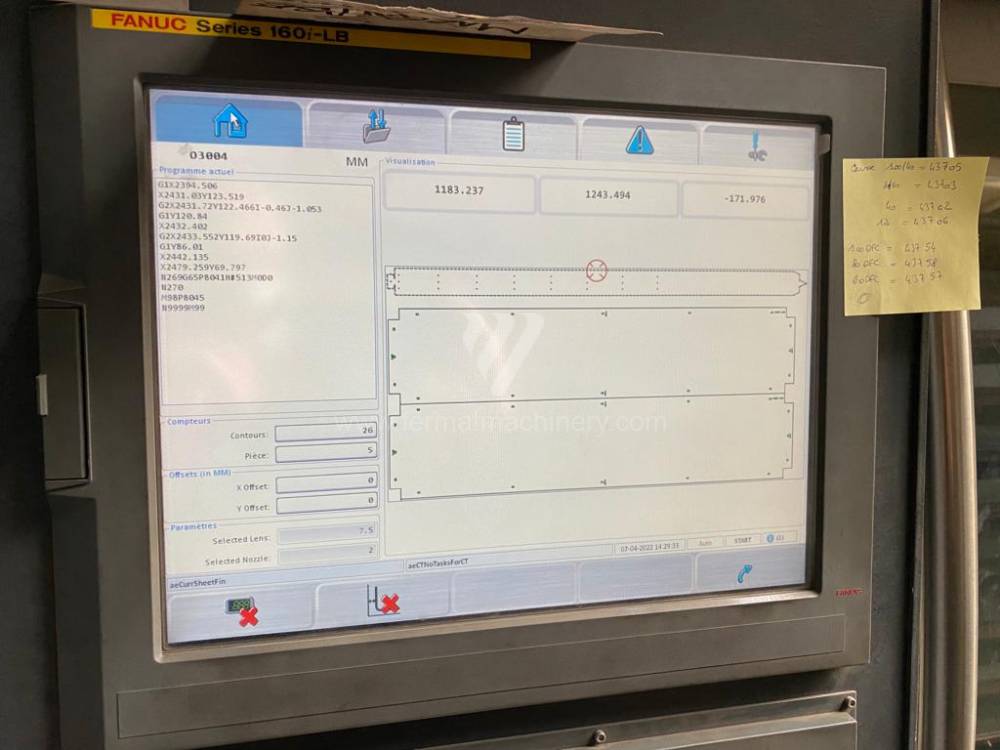

Among the well known and the most modern laser cutting machines are 2D lasers which are used for cutting sheet metal up to 200 x 6000 mm in size. Lasers are divided according to the type of technology between CO2 lasers with resonator powers up to 20 kW for cutting and welding and solid-state lasers called fibers with power up to 6 kW.

Lasers for 3D cutting are used for cutting shaped surfaces in pipes, profiles, etc. up to a length of 6000 mm and for welding on complex parts for the automotive industry. The most popular producers of these lasers are Trumpf, Bystronic, Amada, Prima Power, Mazak.

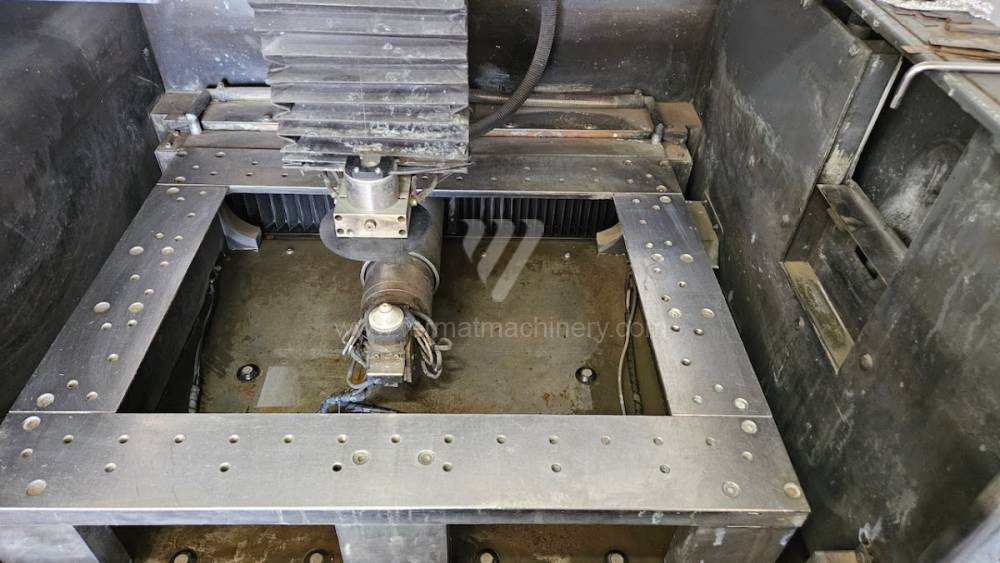

Water jet or water cutting machines with added abrasive are used for cutting and shape cutting of all metal and non-metal materials, including stone, ceramics, glass, composite materials, textiles etc. from 1,5 mm thickness and up to more than 250 mm. Well known manufacturers are Flow Waterjet, PTV, Rychlý TOM, Bystronic, Omac.

For the traditional cutting of metal sheets are used machines with plasma source (Kjellberg, Hypertherm or Formica) or autogen up to 12000 mm length of the sheet. The main manufacturers of these machines are VANAD, MGM, Pierce Automation, ESAB, Microstep, Messer. Plasma cuts materials up to 30 mm thick. Autogen can cut steel up to 1000 mm in thickness.

In the category of saws, we can find both circular and band saws CNC controlled, semi-automatic or gravity-fed. Most popular producers are Kasto, Pegas, Kaltenbach, BLM, Adige, Pilous, Bomar, Meba.

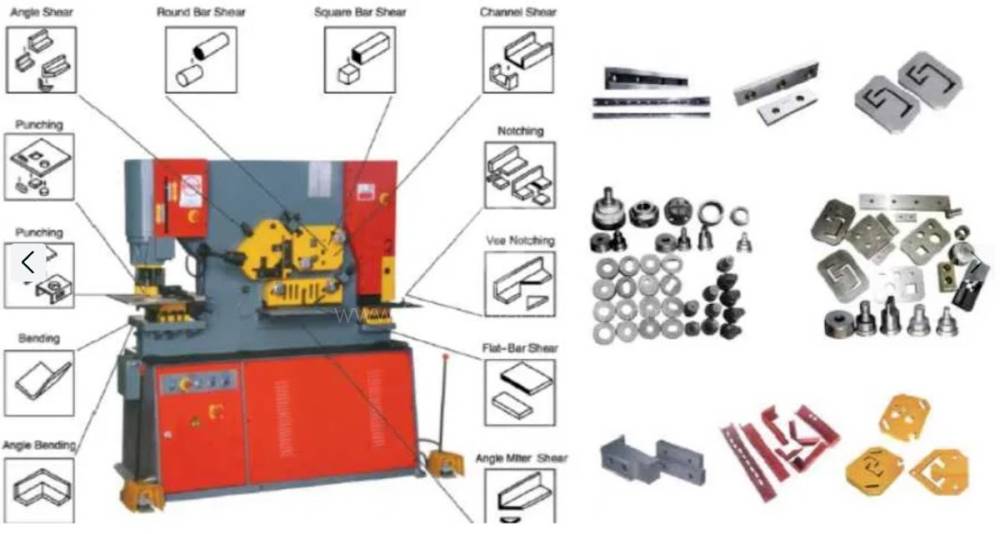

A separate subcategory are wire cutting machines, sometimes named as electrospark or electroerosion machine, shortly EDM (Electric Discharge Machining) which remove the material with tiny electric discharges in a liquid dielectric. The Main advantage is that machine can work even with hard materials too. These machines are used for production of tools, punches etc. Among the main manufacturers of these EDM machines are Charmilles Technologies, Agie, Fanuc, Sodick, Mitsubishi Electric, Hitachi, Accutex, Makino..