Cerrar

Año de fabricación:2022

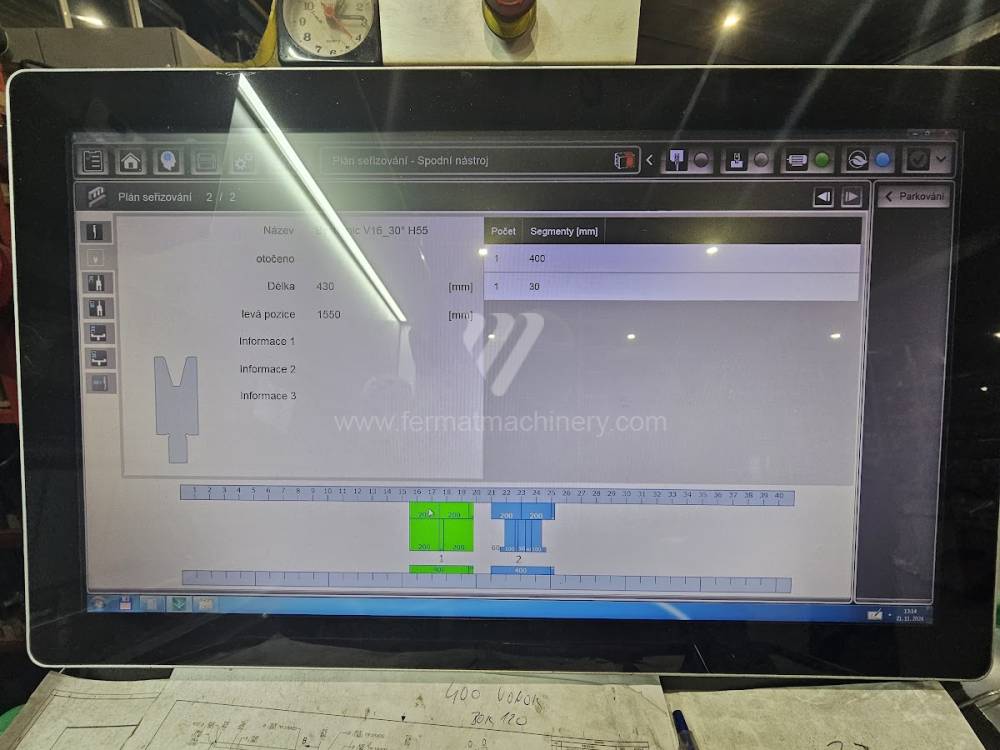

Sistema de control Delem: DA - 69 T

Fuerza de presión: 400 t

Longitud de plegado: 6100 mm

Número de ejes accionados: 8

Compensación del movimiento bajo: Sí

Tipo de accionamiento de la prensa: Hydraulický

Año de fabricación:1998

Fuerza de presión: 220 t

Longitud de plegado: 3000 mm

Número de ejes accionados: 5

Compensación del movimiento bajo: No

Tipo de accionamiento de la prensa: Hydraulický

Peso de la máquina: 13500 kg

Año de fabricación:2018

Fuerza de presión: 36 t

Longitud de plegado: 1020 mm

Número de ejes accionados: 8

Compensación del movimiento bajo: No

Tipo de accionamiento de la prensa: electro-mechanical

Carrera del martinete: 120 mm

Año de fabricación:2018

Fuerza de presión: 320 t

Longitud de plegado: 4100 mm

Número de ejes accionados: 8

Compensación del movimiento bajo: Sí

Tipo de accionamiento de la prensa: Hydraulický

Carrera máx. del martinete: 565 mm

Año de fabricación:2002

Sistema de control SAFAN: TS 1

Fuerza de presión: 50 t

Longitud de plegado: 2550 mm

Número de ejes accionados: 4

Compensación del movimiento bajo: No

Tipo de accionamiento de la prensa: Elektrický

Año de fabricación:2002

Fuerza de presión: 120 t

Longitud de plegado: 3100 mm

Número de ejes accionados: 3

Compensación del movimiento bajo: Sí

Tipo de accionamiento de la prensa: Hydraulický

Carrera del martinete: 180 mm

Forming machines used for processing (bending) of sheet metal. These machines are currently replaced by bending machines, because they are hydraulically driven and can work with greater pressures and lengths of bent parts.

During this kind of material processing , there is no waste and semi-finished products are used. It is also possible to bend very small workpieces of very small radius.

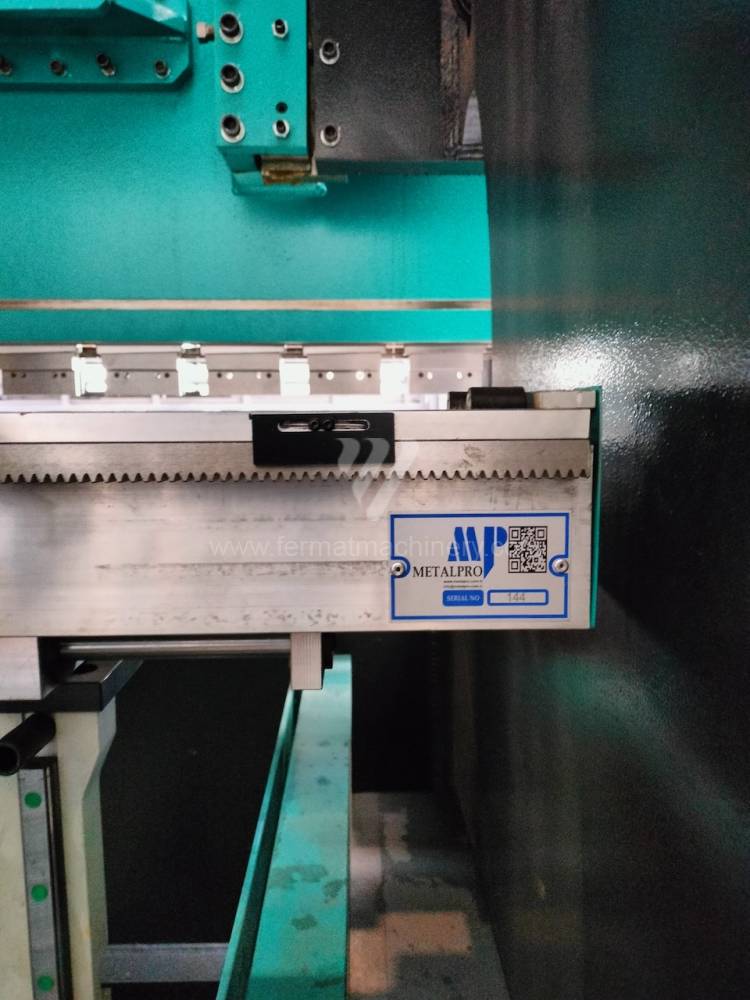

Different types of punches and dies are used here as tools. These tools can be of different shapes and lengths. To clamp these tools mechanical or hydraulic clamping is used. Laser inspection can be used for maximum tool accuracy. Mechanical systems are used to drive the press, with an electric motor driving a system of pulleys and belts. Or a hydraulic one, which drives the hydraulic unit via an electric motor and the latter moves the ram through the pressure of the cylinders.

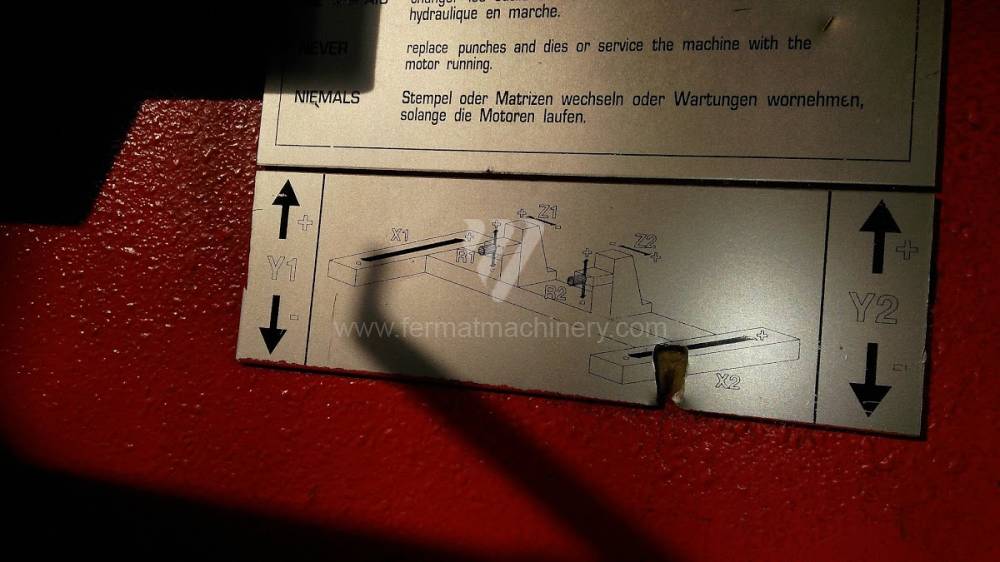

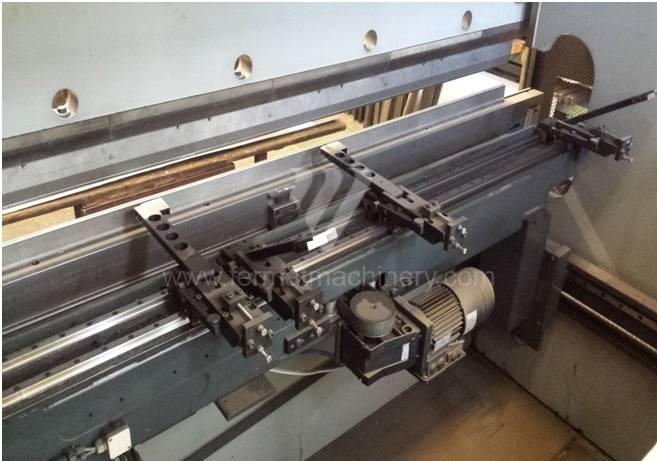

The rear stop is very important for a press brake. It ensures the correct positioning of the workpiece in the machine. Semi finished product is pressed against the thumb, which is on the stop and ensures the correct position with respect to the tool. The rear stop is controlled by a CNC system and it moves to precise positions according to the program. Machine can operate in up to 6 axes.

X - along which the stop moves forward and backward

Z - along which the stop moves to the left or to right

R - along which the stop moves up and down

Another important function of press brakes is cambering. It is a process when the the long parts are bended the resistance of the material to the upper tool, elastic deformation of the part of the ram with the punch occurs. This can be prevented by underlying the matrix in the central part, grooves on the edges of the working table or automatic system.

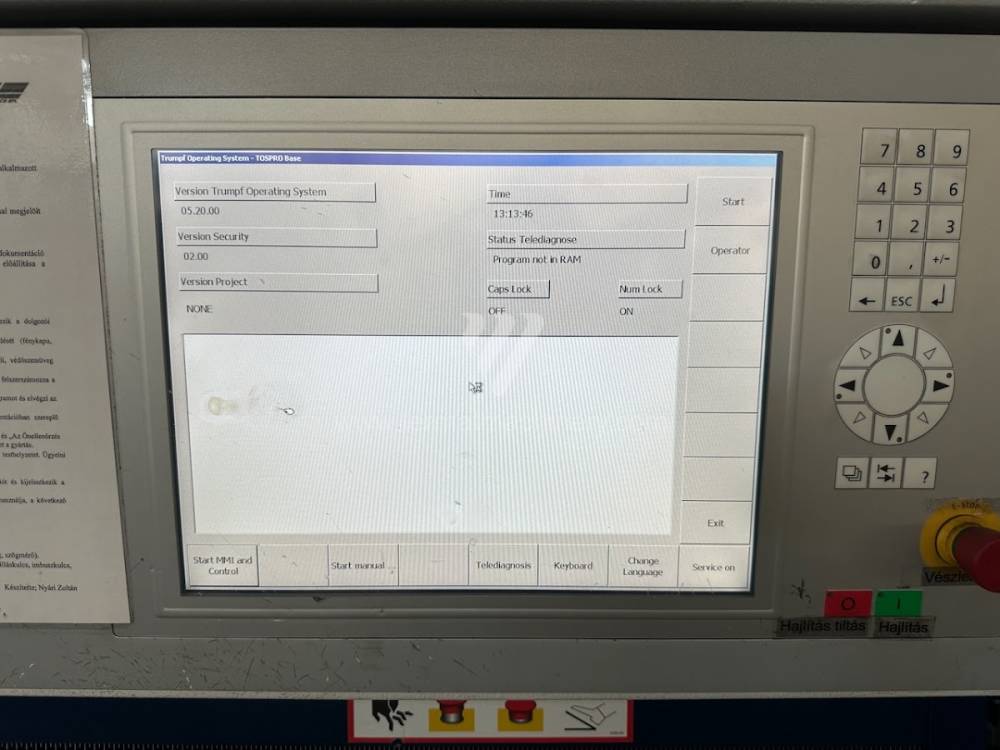

Today, press brakes are controlled by a computer systems. Based on the entered values (material, tools, length, etc…) calculates the production process, the movement of the stops or the bending force. Afterwards the machine can work in three following modes .

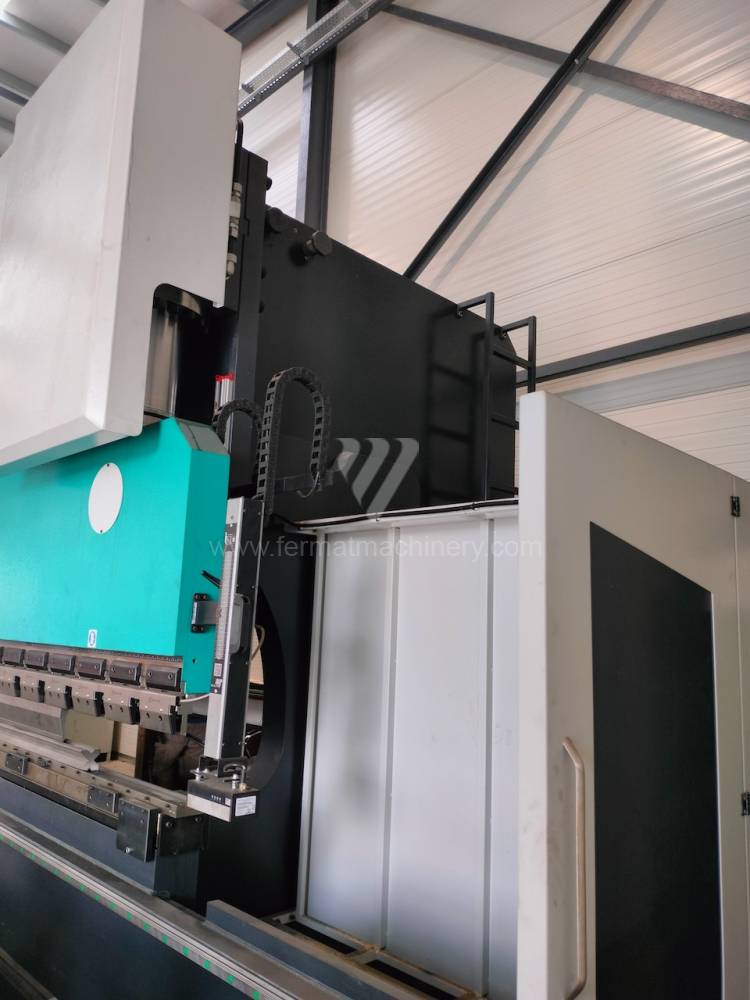

Press brakes are designed with different types of drivers such as machines with manual control, mechanical or hydraulic driver. Each has its advantages and disadvantages. Furthermore, it is possible to divide press brakes according to their construction into segmental, tandem and combined.

Most popular manufacturers are TRUMPF, DURMA, SAFAN DARLEY, BYSTRONIC, GASPARINI, Haco, Beyeler, Promecam, Hämmerle.

Currently, the most widely used and manufactured are hydraulic press brakes, which are CNC controlled.Top machines are from following manufacturers: Trumpf, Amada, Bystronic. These manufacturers use either their own CNC system for control or universal ones such as Delem, Cybelec, ESA.. These machines achieve a high level of automation of the operating cycles and therefore the maximum use of their capabilities. Of course press brakes from these top manufacturers are very expensive to purchase.