Vicino

Anno di fabbricazione:2002

Sistema di controllo Fanuc:

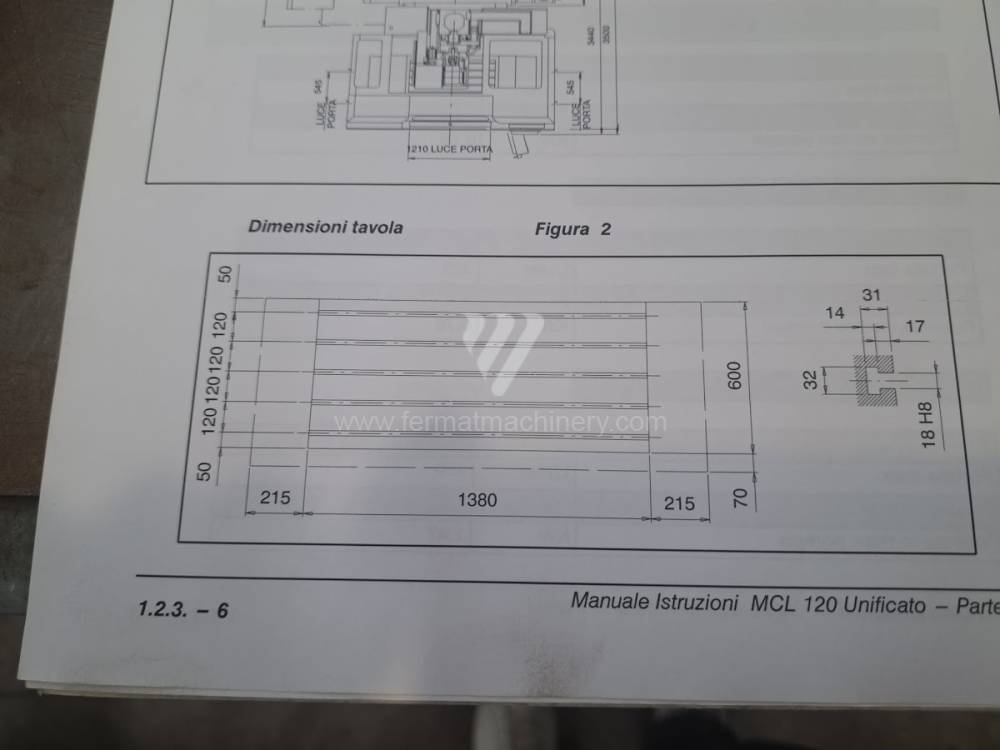

Superficie di bloccaggio del banco: 1380x620 mm

Spostamento asse X: 1200 mm

Spostamento asse Y: 600 mm

Spostamento asse Z: 600 mm

Giri del mandrino: 50 - 10000 /min.

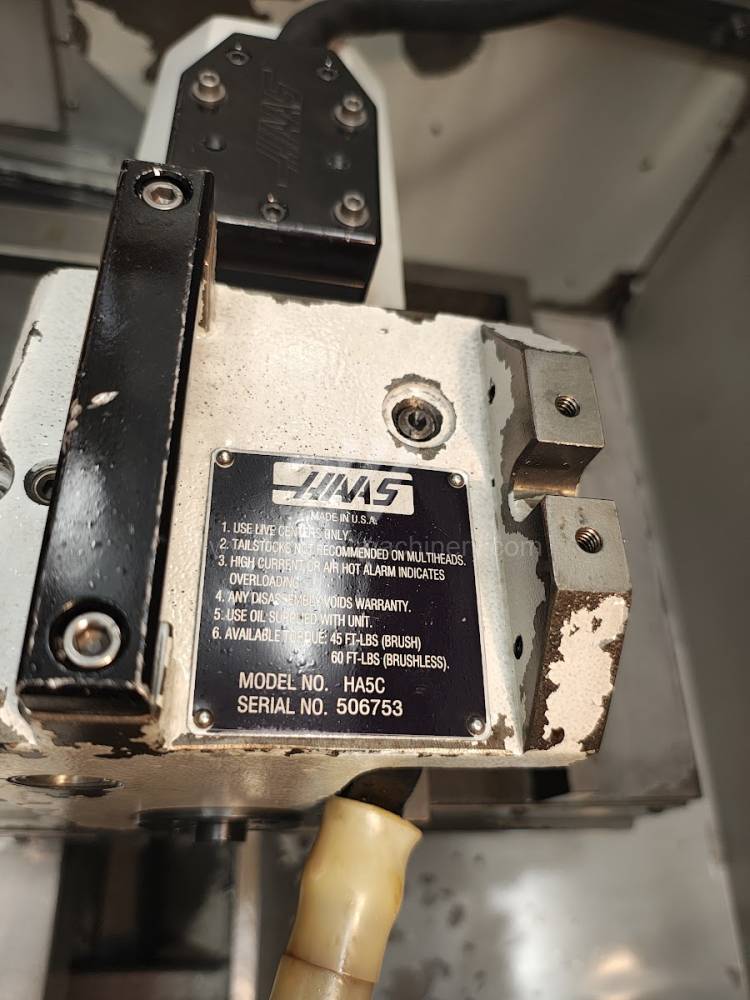

Anno di fabbricazione:2001

Sistema di controllo Haas:

Superficie di bloccaggio del banco: 730 x 305 mm

Spostamento asse X: 406 mm

Spostamento asse Y: 305 mm

Spostamento asse Z: 320 mm

Giri del mandrino: 0 - 6000 /min.

Anno di fabbricazione:2006

Sistema di controllo Heidenhain: TNC 530

Superficie di bloccaggio del banco: 1800X780 mm

Spostamento asse X: 2030 mm

Spostamento asse Y: 810 mm

Spostamento asse Z: 810 mm

Giri del mandrino: 0 - 8000 /min.

The machining center is intended for milling, drilling, boring, threading. These centers are highly productive machines for complex chip machining of metals, wood, plastic, rubber, teflon, graphite or glass.

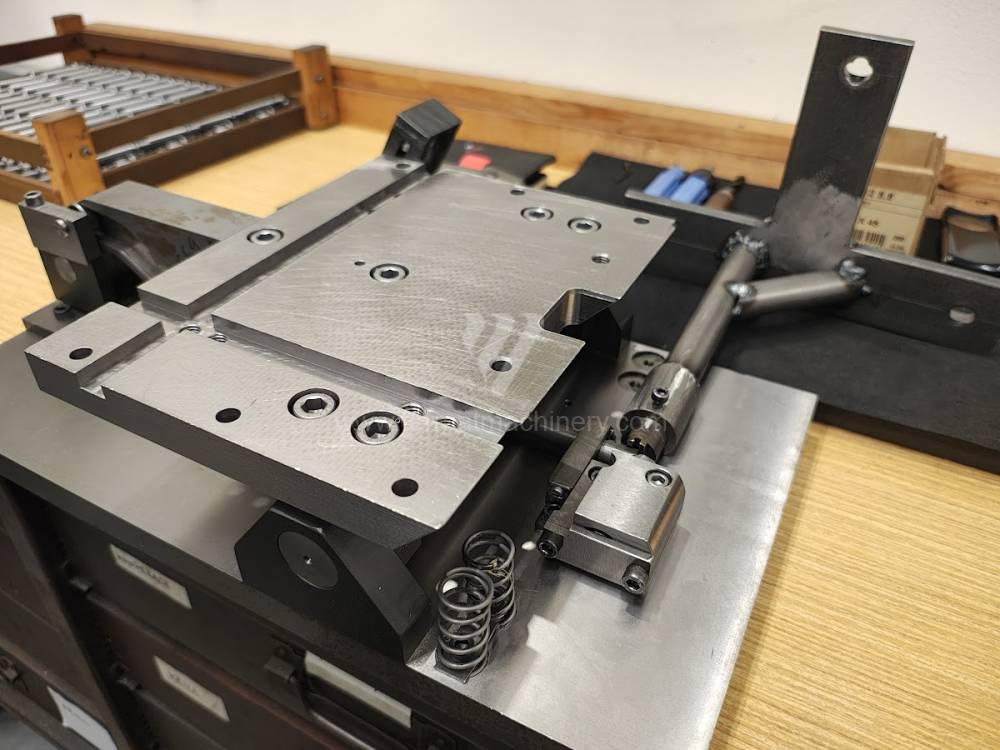

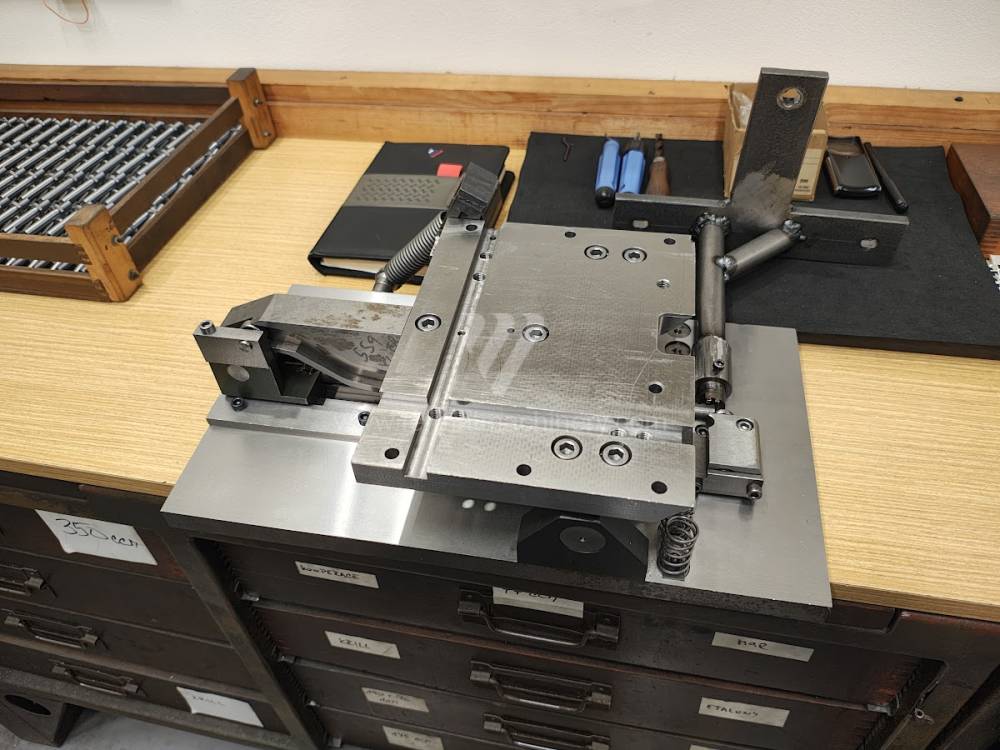

The basic design has 3 CNC axes controlled X,Y,Z. Is equipped with an automatic tool changer. These machines can be also equipped with 4th and 5th CNC controlled axes.

The most interesting group of machining centers are 5th axis machines which have simultaneously controlled X,Y,Z,B and C axes and thus they can be used to produce the most complex shapes, such as turbine blades, molds and other technologically demanding workpieces.

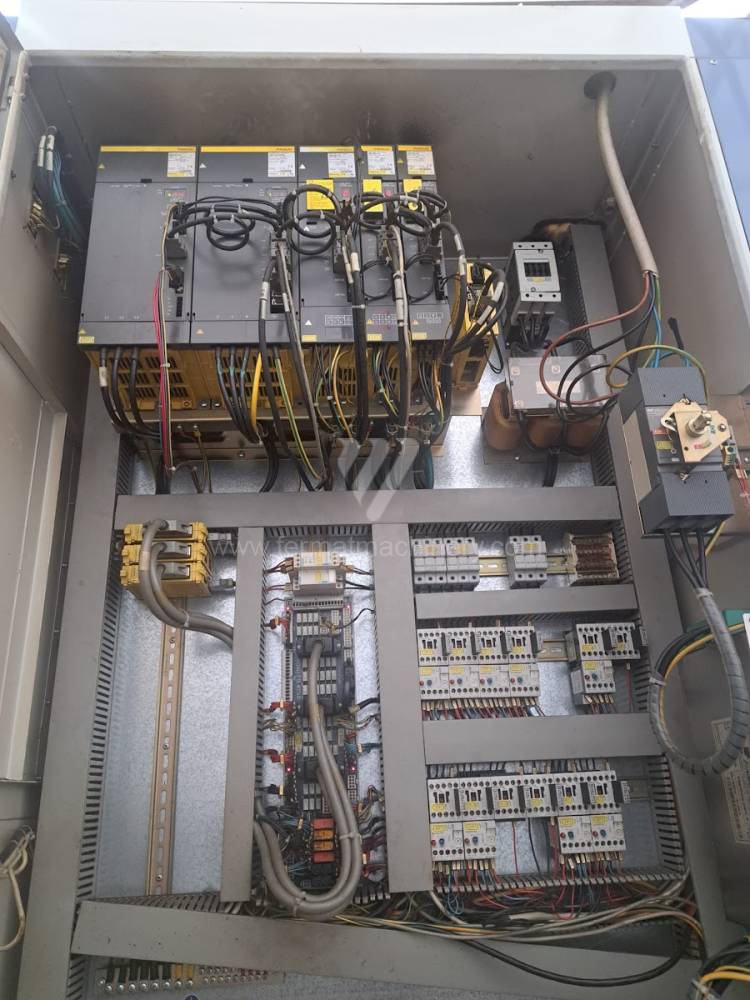

Machines are controlled with a control system. Among the most popular control systems are: Heidenhain, Siemens, Fanuc, Mazatrol or HAAS.

The most popular producers or machining centers we can talk about are Hermle, DMG MORI, MAZAK, Doosan, Fanuc, HAAS, Kovosvit MAS, Okuma, Tajmac-ZPS and many others.

According to the position of the spindle we can differentiate machining centers on vertical or horizontal.