Close

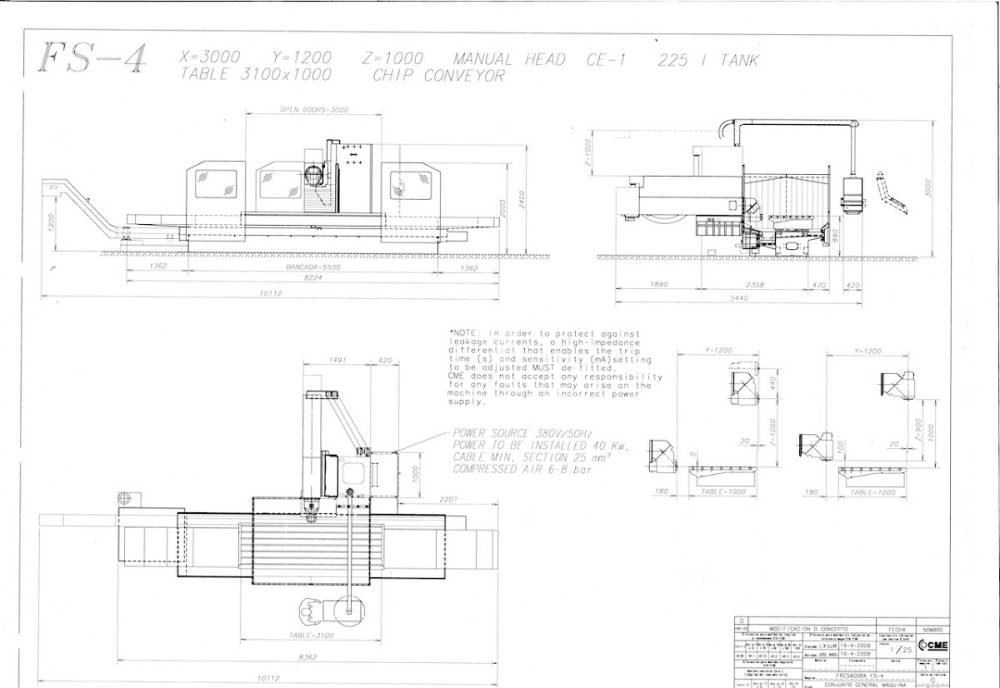

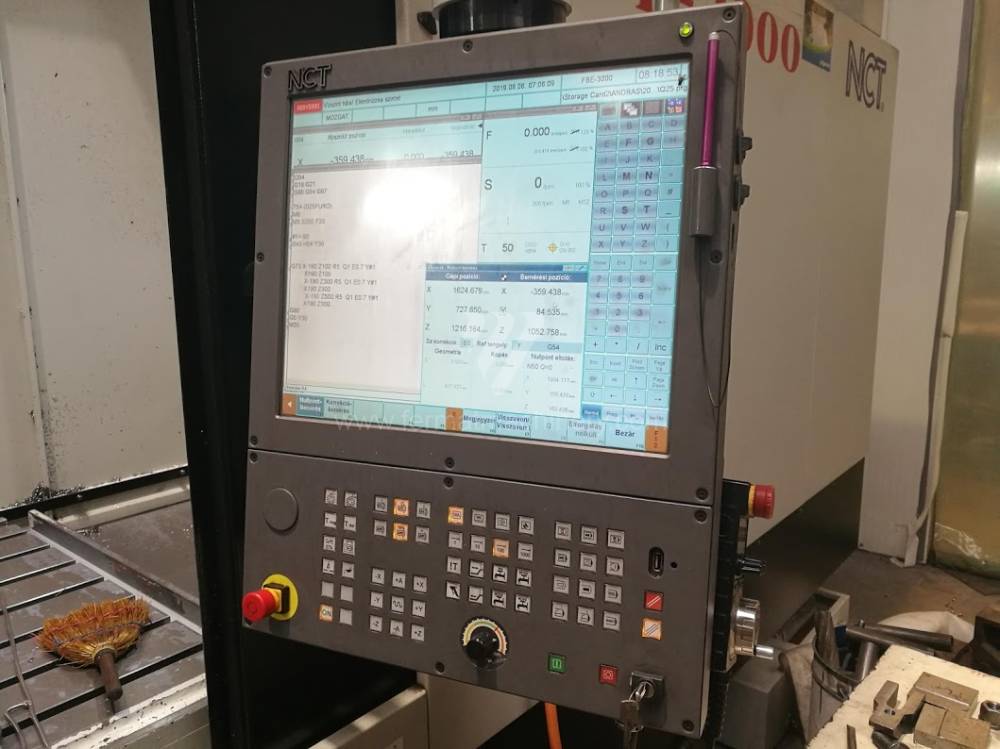

YOM:2008

Control system NCT: 104

Dimensions of table working surface: 3100x1000 mm

Travel X-axis: 3000 mm

Travel Y-axis: 1200 mm

Travel Z-axis: 1000 mm

Spindle speed: 0 - 4000 /min.

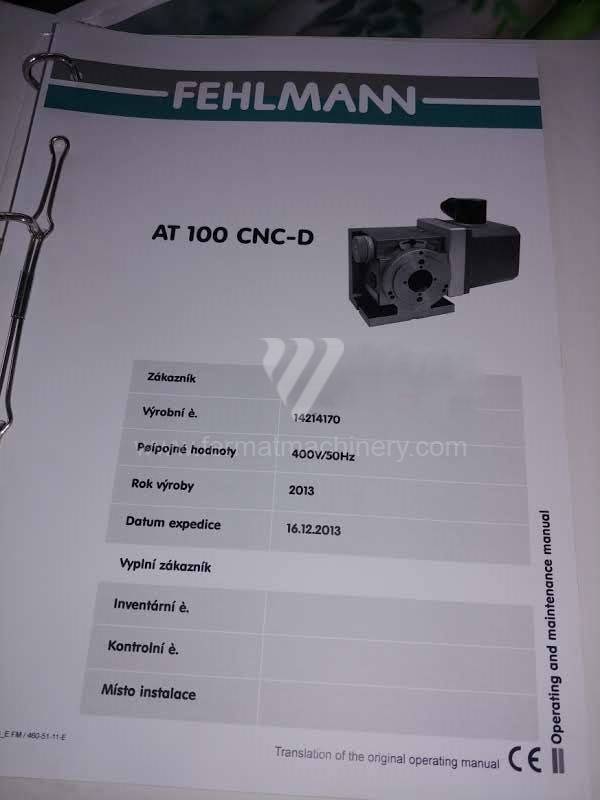

YOM:2013

Control system Heidenhain: TNC 620

Dimensions of table working surface: 908x480 mm

Travel X-axis: 500 mm

Travel Y-axis: 400 mm

Travel Z-axis: 400 mm

Spindle speed: 50 - 12000 /min.

YOM:1986

Dimensions of table working surface: 1800 x 570 mm

Travel X-axis: 1400 mm

Travel Y-axis: 670 mm

Travel Z-axis: 500 mm

Main motor power: 15 kW

Spindle speed: 0 - 1400 /min.

YOM:1985

Dimensions of table working surface: 1400 x 400 mm

Travel X-axis: 1000 mm

Travel Y-axis: 400 mm

Travel Z-axis: 450 mm

Spindle taper: ISO 50 .

Spindle speed: 10 - 1800 /min.

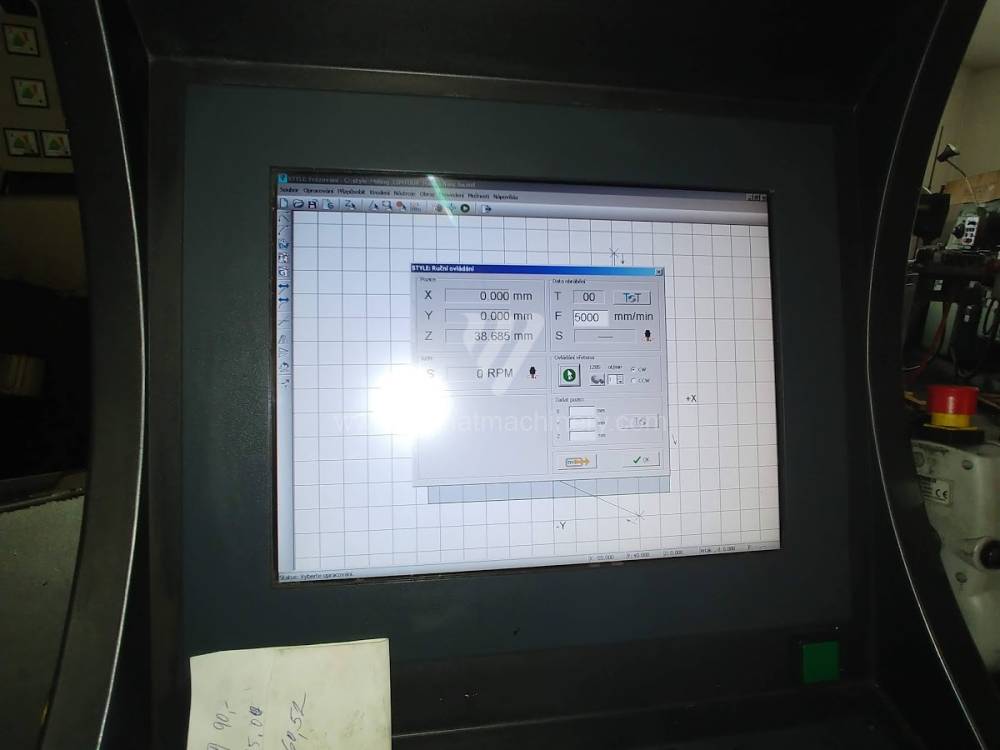

YOM:2003

Control system STYLE:

Dimensions of table working surface: 1520x510 mm

Travel X-axis: 1320 mm

Travel Y-axis: 660 mm

Travel Z-axis: 700 mm

Spindle speed: 1 - 6000 /min.

YOM:2015

Control system NCT: 201

Dimensions of table working surface: 3100 x 1050 mm

Travel X-axis: 3000 mm

Travel Y-axis: 1000 mm

Travel Z-axis: 1500 mm

Rapid feed: 10/10 /10 m/min

YOM:1978

Dimensions of table working surface: 2000x425 mm

Travel X-axis: 1400 mm

Travel Y-axis: 440 mm

Travel Z-axis: 450 mm

Main motor power: 11 kW

Machine weight: 5170 kg

YOM:1992

Dimensions of table working surface: 600 x 300 mm

Travel X-axis: 450 mm

Spindle taper: SK 40 .

Travel Y-axis: 300 mm

Travel Z-axis: 350 mm

Spindle speed: 63 - 3150 /min.

YOM:1998

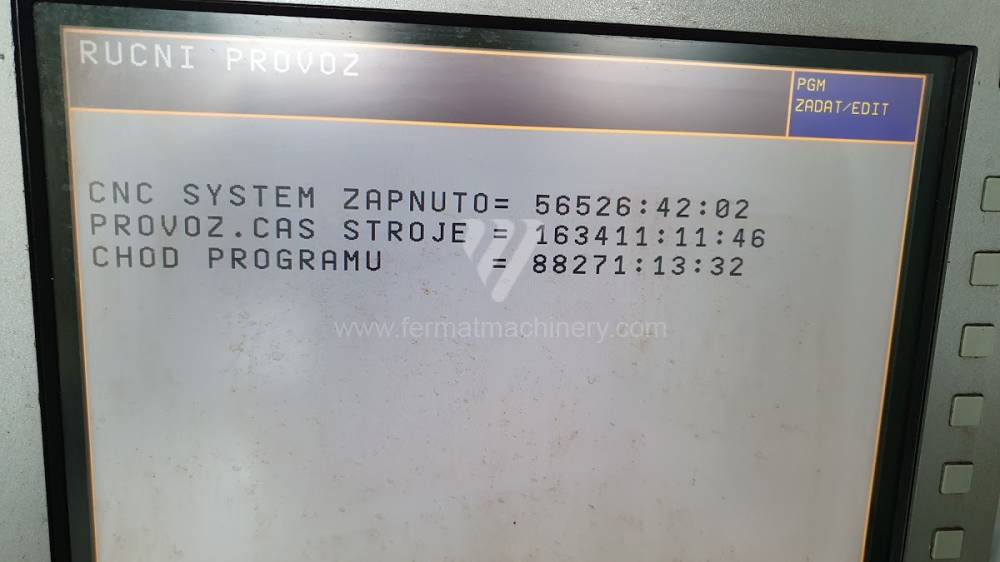

Control system Heidenhain: TNC 430

Dimensions of table working surface: 4000 x 1000 mm

Travel X-axis: 4000 mm

Travel Y-axis: 1000 mm

Travel Z-axis: 1400 mm

Max. weight of workpiece: 8500 kg

Console type – console is moving here in the vertical Z axis and supporting a cross table which is moving along X and Y axis.

Tool type – compact one, mainly for tool shops.

Table type – with the larger table which is moving along the bed in traverse direction on X axis with retractable headstock in Y axis suspended from the column along which it moves in the vertical direction of the Z axis. For machining the milling head is used and can be adjusted horizontally or vertically. Milling head can be also indexed in the B axis, or continuously controlled in two axes.

Plano type – with a two-column gantry carrying a crossbar with a spindle moving along it in the Y axis and retractable in the Z axis. Further it is divided into:

Rolling type – for production of the gears.

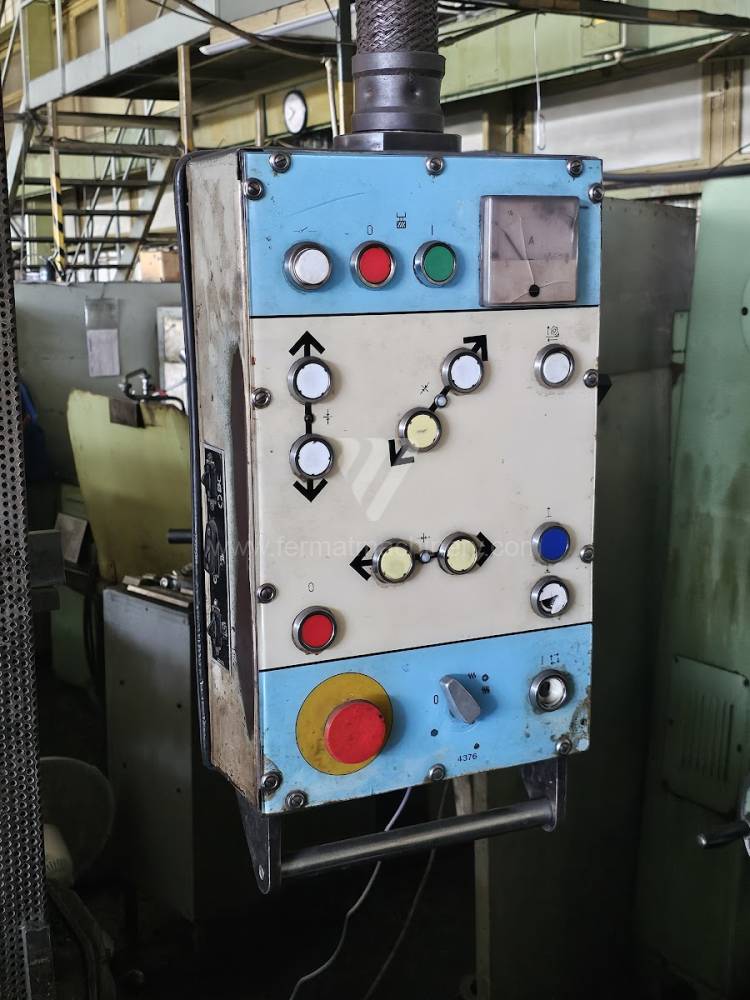

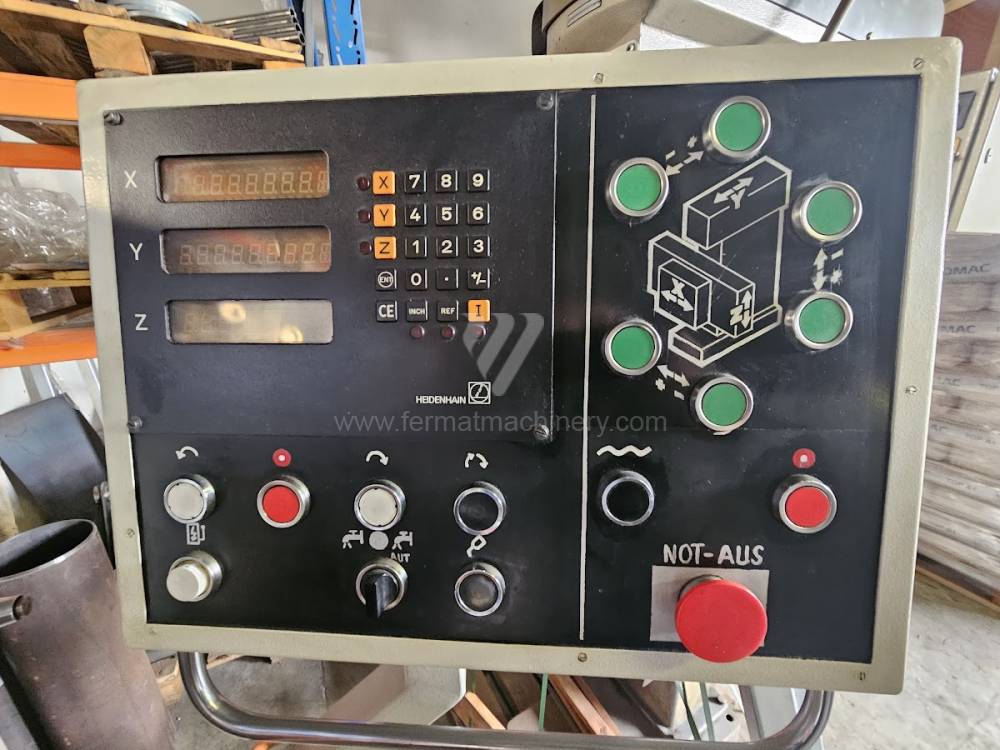

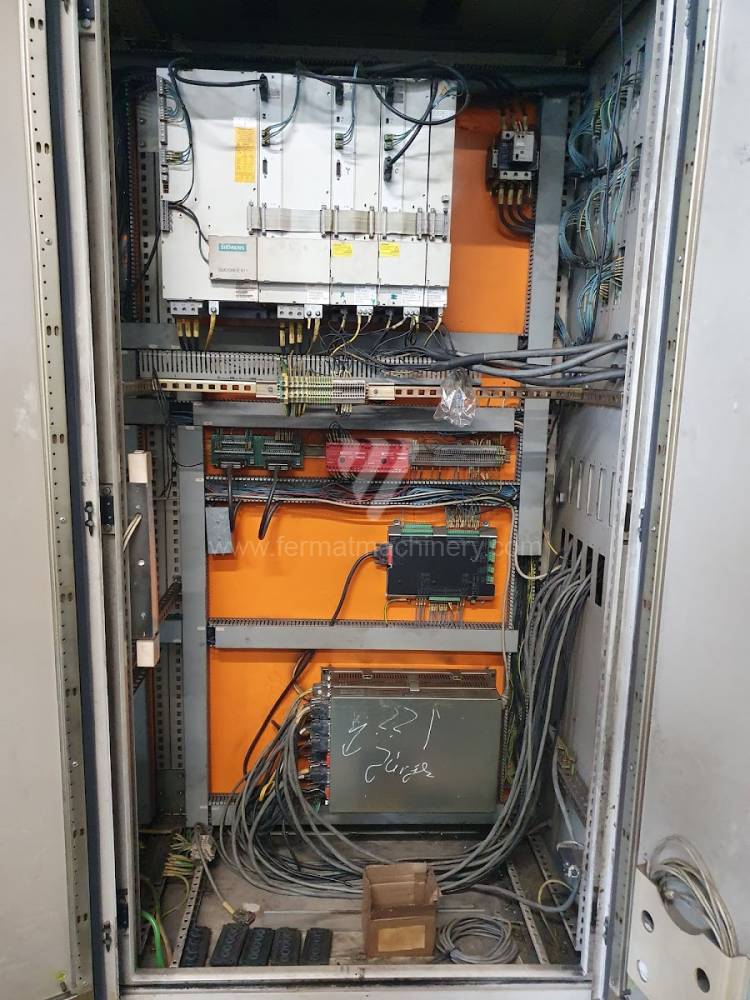

Milling machine can be controlled manually using buttons, levers and wheels. More modern ones are equipped with digital readout of X,Y,Z axes or with regular CNC control. Most common are systems from producers HEIDENHAIN, SIEMENS, FANUC or FAGOR.

The most famous and traditional brand of milling machines in Czech Republic is TOS Kurim, which is manufacturing wide range of milling machines from small tool machines to the largest portal ones. Not even TOS Kurim is engaged in manufacturing such machines. There are also other TOS companies such as – TOS Olomouc a TOS Čelákovice, or INTOS. Among the world manufacturers of milling machines SHW, CME, MTE, SORALUCE a ZAYER, Italian EMCO or American producer LAGUN.

In case of portal milling machines the main competitor of TOS is Taiwan company HARTFORD, KAO MING, LEADWELL or SMTCL, furthermore German WALDRICH COBURG, Spanish producers CORREA a SORALUCE, or MAZAK and OKUMA from Japan which are using their own CNC systems same as HAAS or HURCO does.