Close

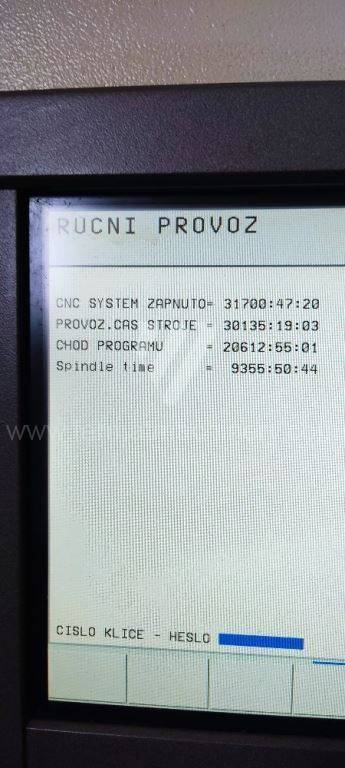

YOM:2004

Control system Heidenhain: TNC 530

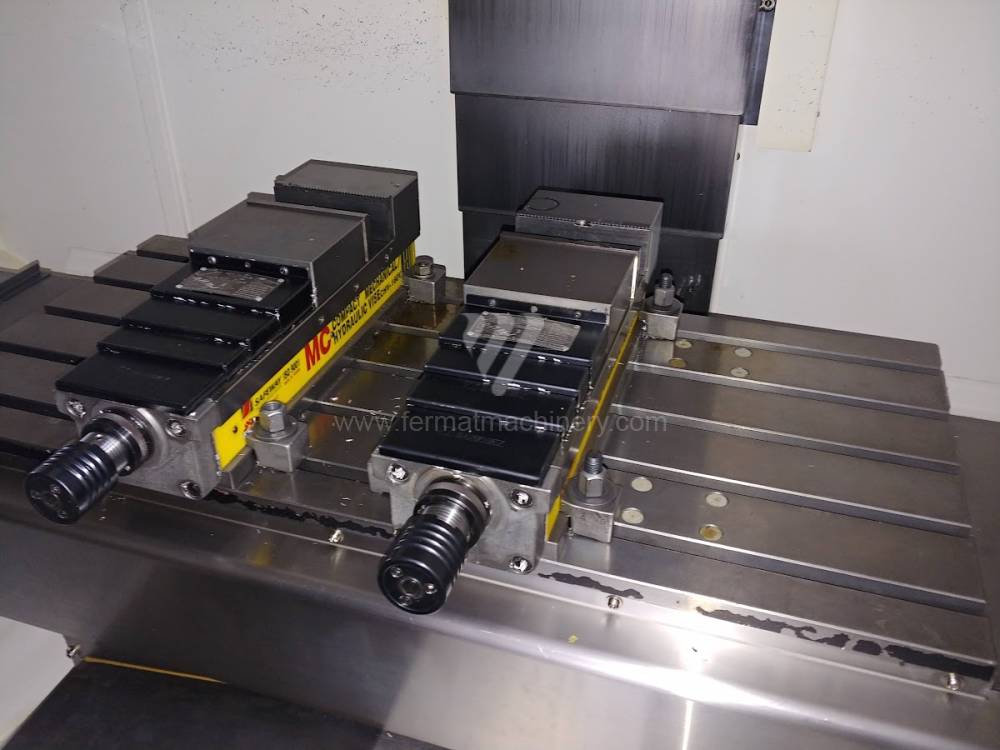

Clamping area of table: 400x400 mm

Travel X-axis: 560 mm

Travel Y-axis: 510 mm

Travel Z-axis: 560 mm

Spindle speed: 10 - 10000 /min.

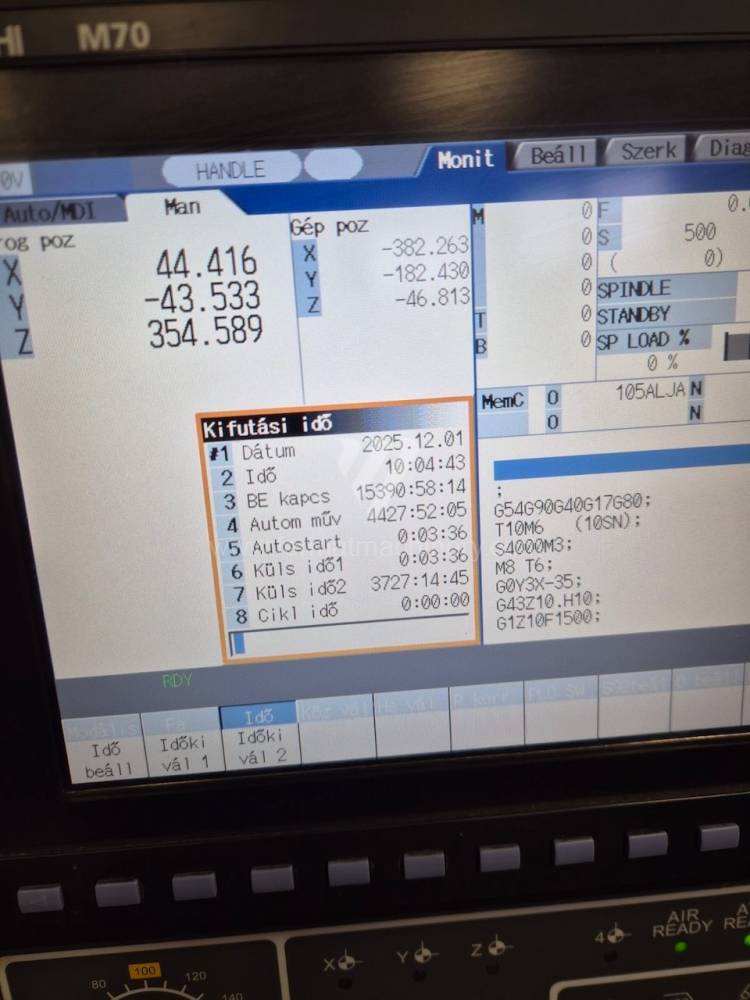

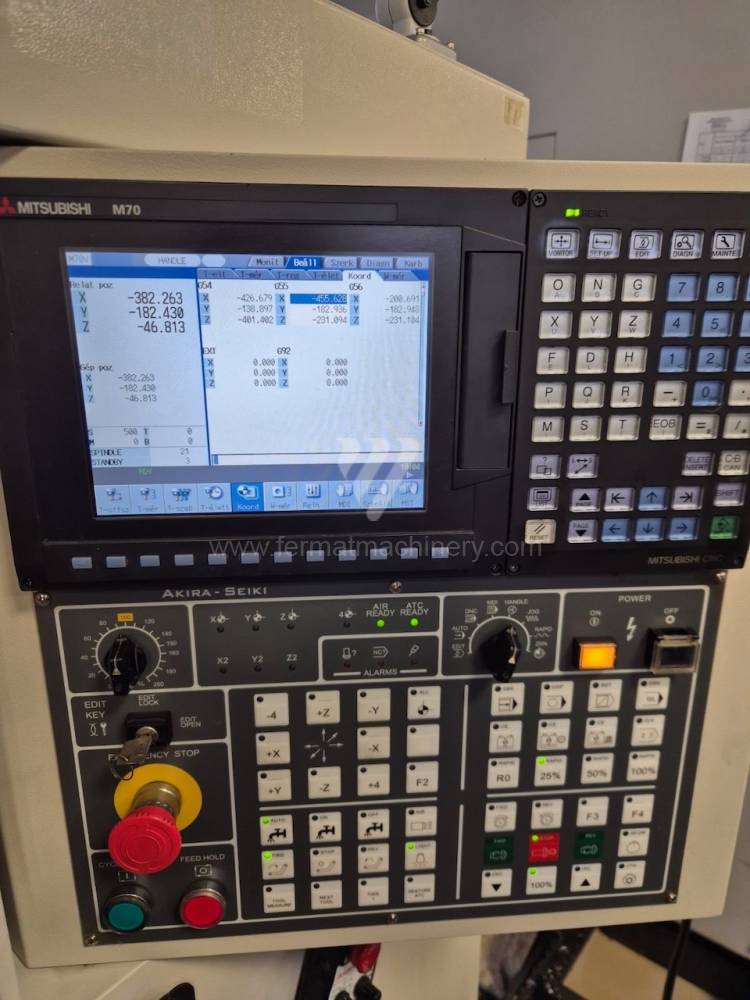

YOM:2013

Control system Mitsubishi: M 70

Clamping area of table: 910x380 mm

Travel X-axis: 762 mm

Travel Y-axis: 410 mm

Travel Z-axis: 460 mm

Spindle speed: 0 - 11000 /min.

YOM:2020

Control system Haas:

Clamping area of table: 914 x 356 mm

Travel X-axis: 762 mm

Travel Y-axis: 406 mm

Travel Z-axis: 508 mm

Spindle speed: 0 - 12000 /min.

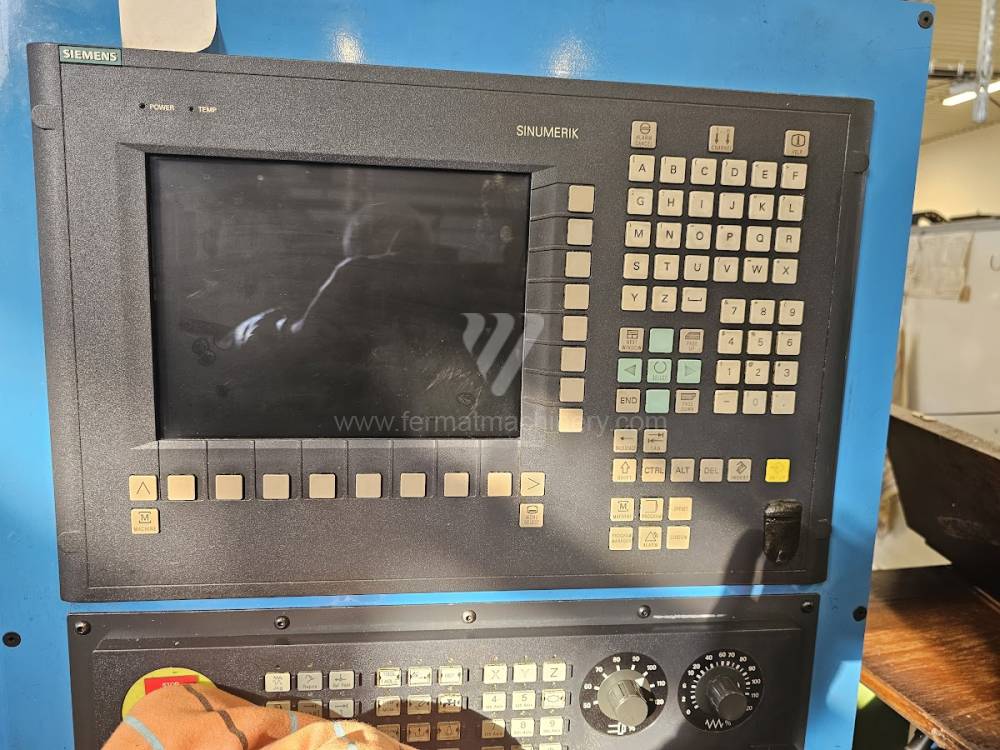

YOM:2003

Control system Siemens:

Clamping area of table: mm

Travel X-axis: 400 mm

Travel Y-axis: 450 mm

Travel Z-axis: 400 mm

Spindle speed: 50 - 12500 /min.

YOM:2010

Control system Heidenhain: TNC 530

Clamping area of table: 790 x 560 mm

Travel X-axis: 635 mm

Travel Y-axis: 510 mm

Travel Z-axis: 460 mm

Spindle speed: 20 - 8000 /min.

YOM:2005

Clamping area of table: 1100 X 600 mm

Travel X-axis: 800 mm

Travel Y-axis: 510 mm

Travel Z-axis: 510 mm

Spindle speed: 12000 - /min.

Number of driven axes: 4

YOM:1995

Clamping area of table: 800 x 500 mm

Travel X-axis: 630 mm

Travel Y-axis: 500 mm

Travel Z-axis: 500 mm

Spindle speed: 0 - 8000 /min.

Number of driven axes: 3

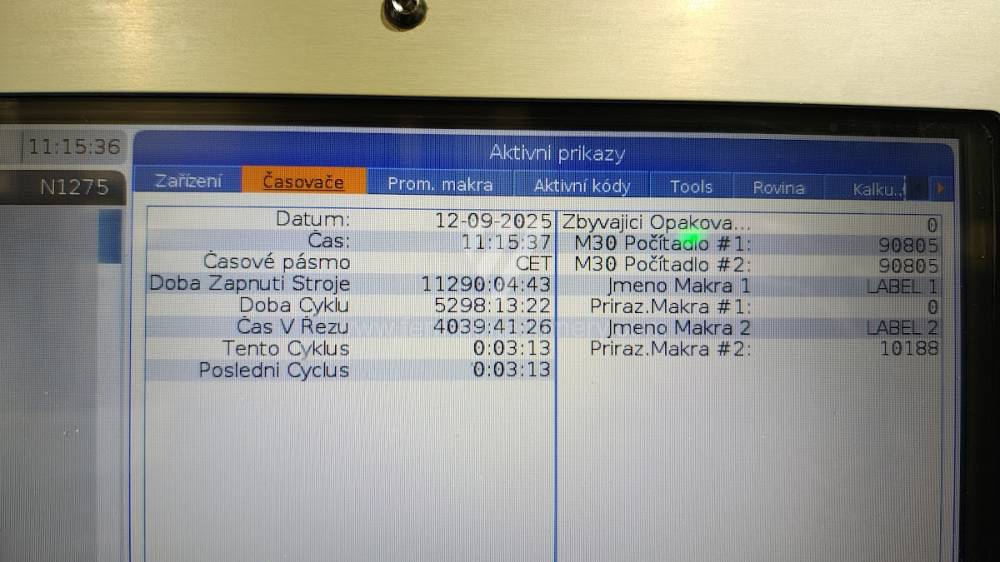

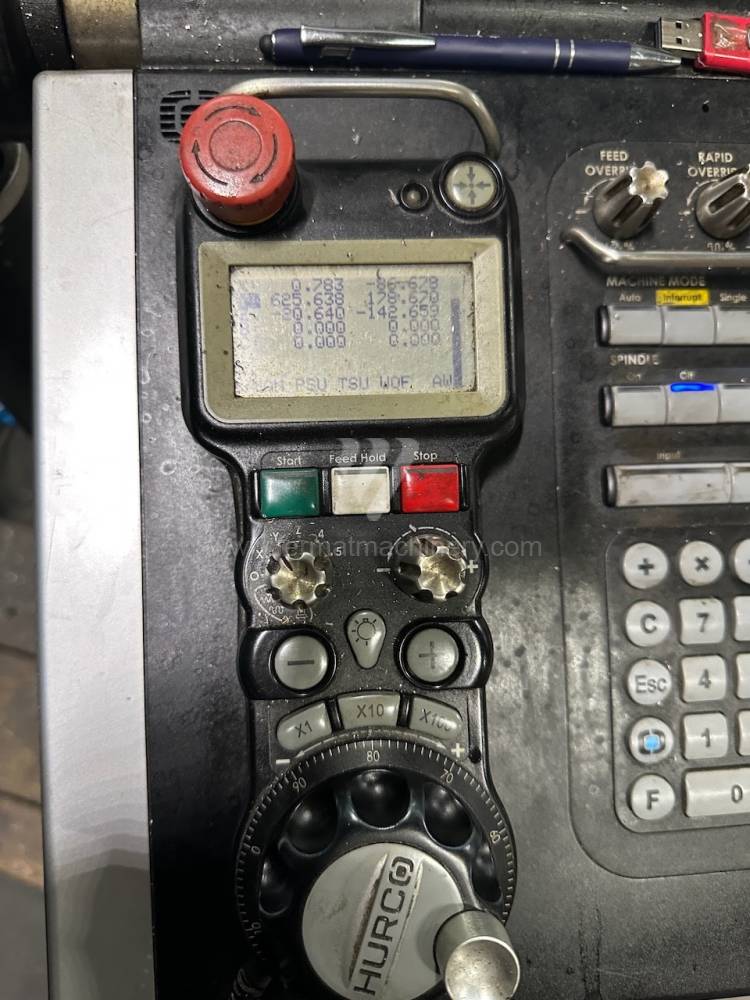

YOM:2015

Control system Hurco: Winmax

Clamping area of table: 1680 x 660 mm

Travel X-axis: 1524 mm

Travel Y-axis: 660 mm

Travel Z-axis: 610 mm

Spindle speed: 0 - 12000 /min.

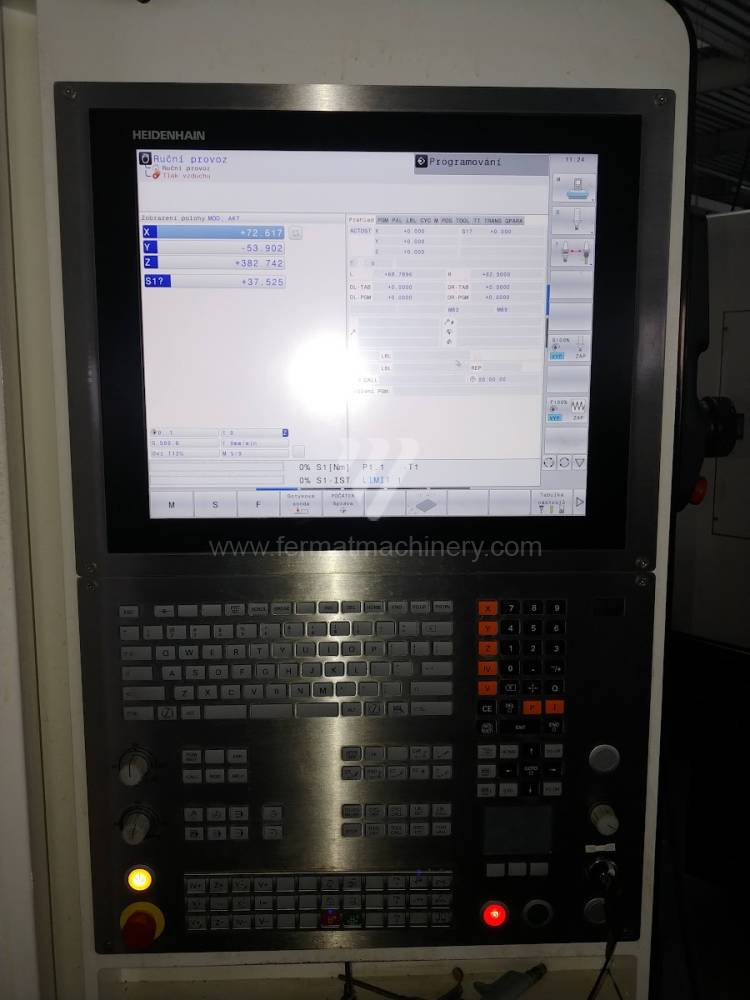

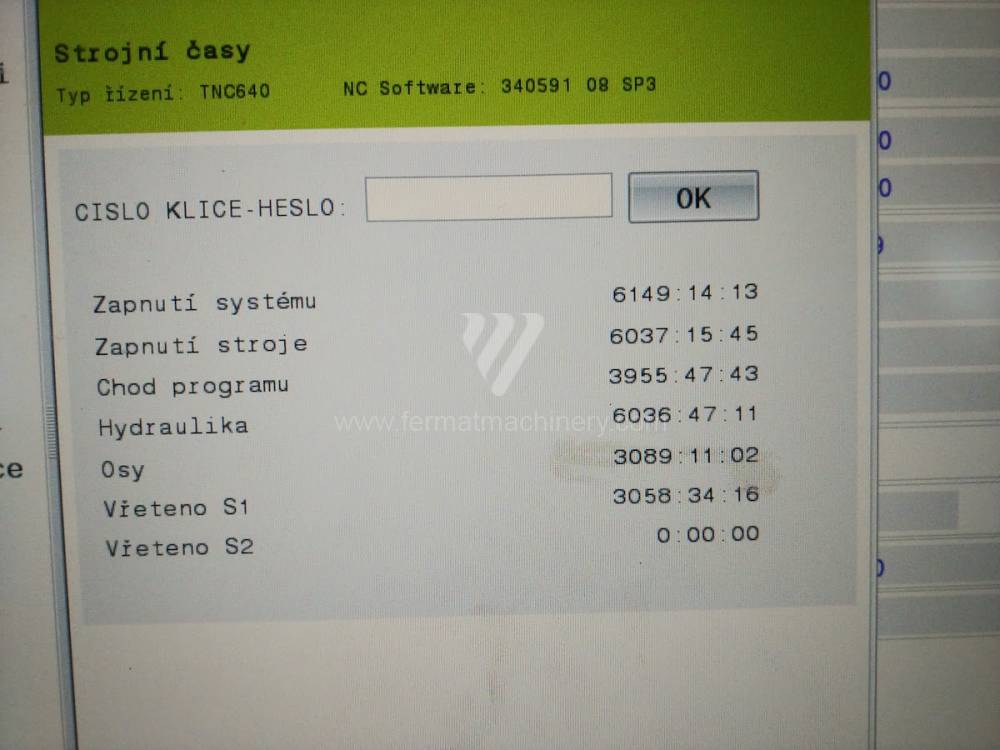

YOM:2018

Control system Heidenhain: TNC 640

Clamping area of table: 1150x520 mm

Travel X-axis: 1020 mm

Travel Y-axis: 520 mm

Travel Z-axis: 550 mm

Spindle speed: 10 - 15000 /min.

YOM:2023

Control system Haas:

Clamping area of table: 600 x 500 mm

Travel X-axis: 610 mm

Travel Y-axis: 406 mm

Travel Z-axis: 406 mm

Spindle speed: 0 - 12000 /min.

YOM:2001

Control system Heidenhain: TNC 530

Clamping area of table: 1000 x 600 mm

Travel X-axis: 630 mm

Travel Y-axis: 560 mm

Travel Z-axis: 560 mm

Spindle speed: 0 - 10000 /min.

YOM:2010

Control system Fanuc: Fanuc 31i

Clamping area of table: 1000x800 mm

Travel X-axis: 1700 mm

Travel Y-axis: 1250 mm

Travel Z-axis: 1800 mm

Spindle speed: 1 - 6000 /min.

YOM:2021

Control system Siemens: Sinumerik 828 D

Clamping area of table: 3 000 x 1 500 mm

Travel X-axis: 3 100 mm

Travel Y-axis: 1 900 mm

Travel Z-axis: 900 mm

Spindle speed: 0 - 10000 /min.

YOM:2000

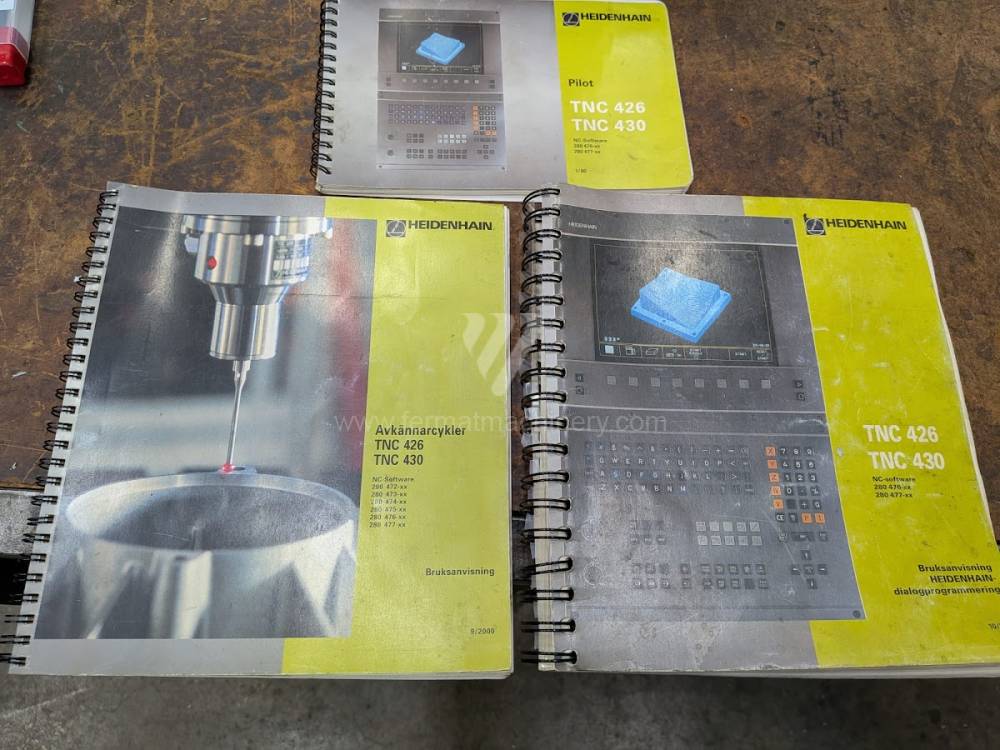

Control system Heidenhain: TNC 426

Clamping area of table: 1300x600 mm

Travel X-axis: 1000 mm

Travel Y-axis: 570 mm

Travel Z-axis: 570 mm

Spindle speed: 1 - 8000 /min.

YOM:2008

Control system Fanuc: 0i - MC

Clamping area of table: 600x360 mm

Travel X-axis: 510 mm

Travel Y-axis: 360 mm

Travel Z-axis: 300 mm

Spindle speed: 120 - 12000 /min.

YOM:2008

Control system Selca: S4045D

Clamping area of table: mm

Travel X-axis: 2300 mm

Travel Y-axis: 750 mm

Travel Z-axis: 700 mm

Spindle speed: 0 - 9000 /min.

YOM:2004

Control system Heidenhain: TNC 530

Clamping area of table: 1300 x 600 mm

Travel X-axis: 1000 mm

Travel Y-axis: 600 mm

Travel Z-axis: 660 mm

Spindle speed: 0 - 10000 /min.

YOM:2005

Control system Mazatrol: Fusion 640 M

Clamping area of table: 400 x 400 mm

Travel X-axis: 510 mm

Travel Y-axis: 510 mm

Travel Z-axis: 460 mm

Spindle speed: 0 - 12000 /min.

YOM:2005

Control system Heidenhain: TNC 530

Clamping area of table: 700 x 500 mm

Travel X-axis: 620 mm

Travel Y-axis: 500 mm

Travel Z-axis: 450 mm

Spindle speed: 0 - 10000 /min.

YOM:2008

Control system Hurco: UltiMax 4

Clamping area of table: 1020 x 510 mm

Travel X-axis: 760 mm

Travel Y-axis: 510 mm

Travel Z-axis: 610 mm

Spindle speed: 10 - 12000 /min.

YOM:1998

Control system Heidenhain: TNC 426

Clamping area of table: 700x400 mm

Travel X-axis: 500 mm

Travel Y-axis: 420 mm

Travel Z-axis: 500 mm

Spindle speed: 0 - 15000 /min.

YOM:2017

Control system Kitamura: Arumatik-Mi

Clamping area of table: 630x630 mm

Travel X-axis: 1100 mm

Travel Y-axis: 920 mm

Travel Z-axis: 1050 mm

Spindle speed: 35 - 12000 /min.

YOM:2007

Control system Fagor: CNC 8050

Clamping area of table: 900 x 410 mm

Travel X-axis: 760 mm

Travel Y-axis: 430 mm

Travel Z-axis: 450 mm

Spindle speed: 0 - 8000 /min.

YOM:2008

Control system NCT:

Clamping area of table: 900x550 mm

Travel X-axis: 800 mm

Travel Y-axis: 500 mm

Travel Z-axis: 550 mm

Spindle speed: 0 - 10000 /min.

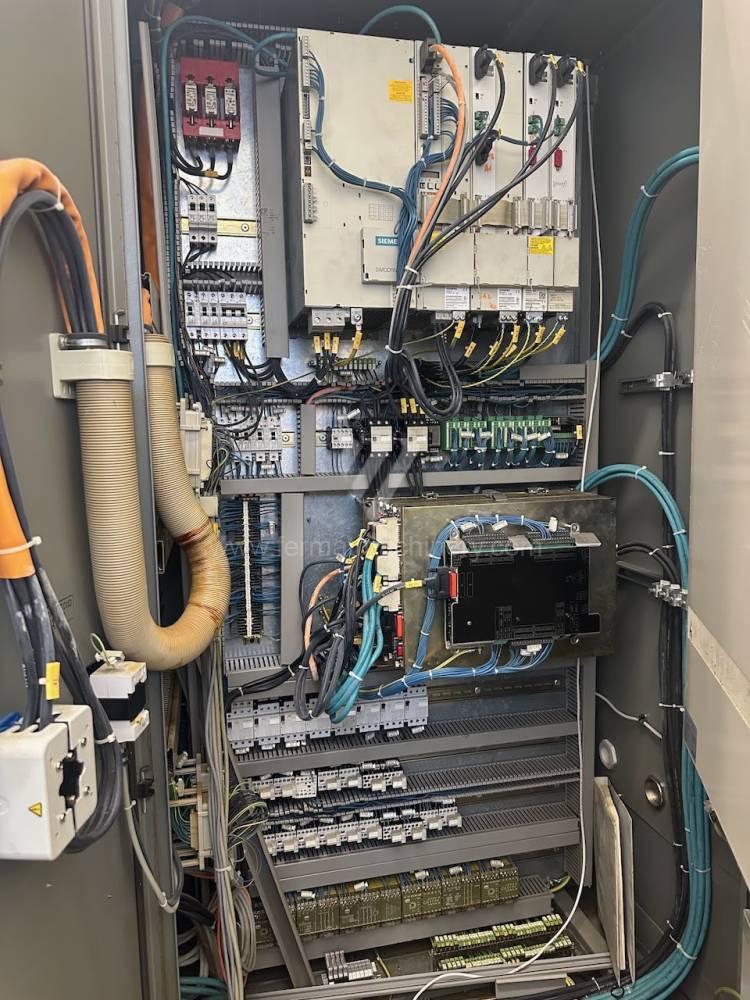

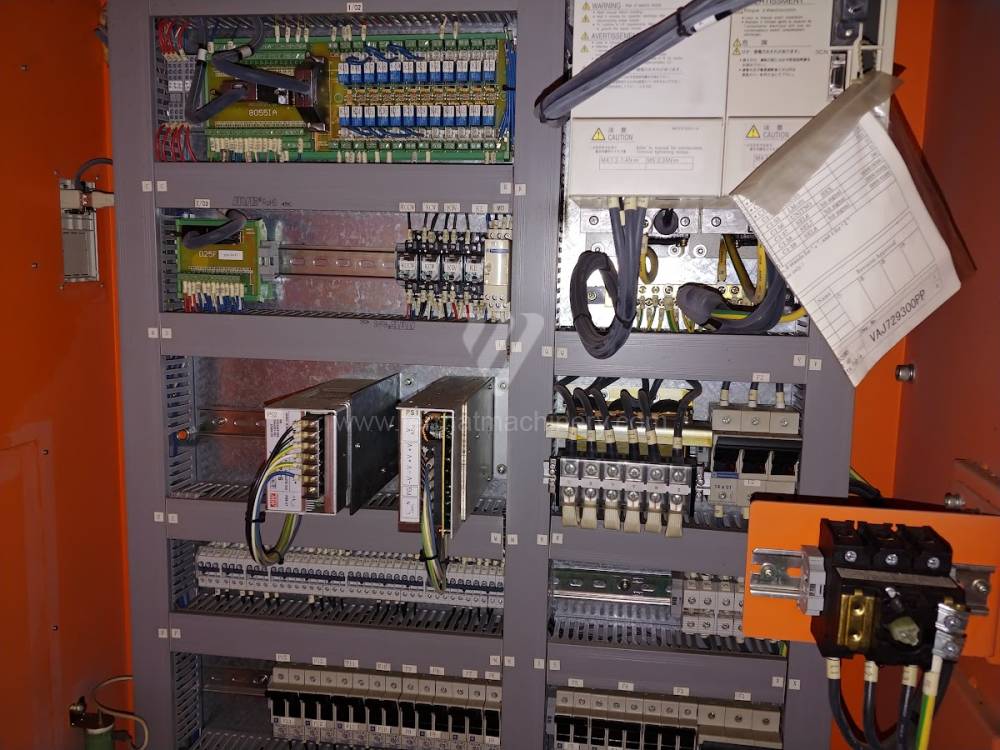

Control system Siemens: Sinumerik 810

Clamping area of table: 1000x510 mm

Travel X-axis: 850 mm

Travel Y-axis: 520 mm

Travel Z-axis: 510 mm

Spindle speed: 0 - 8000 /min.

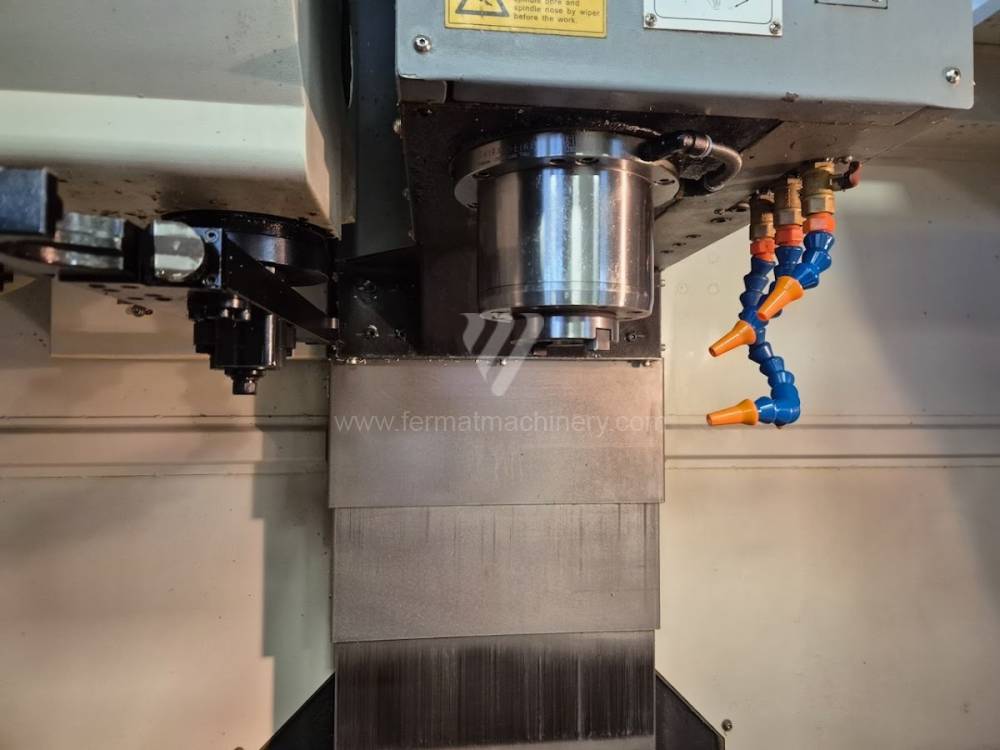

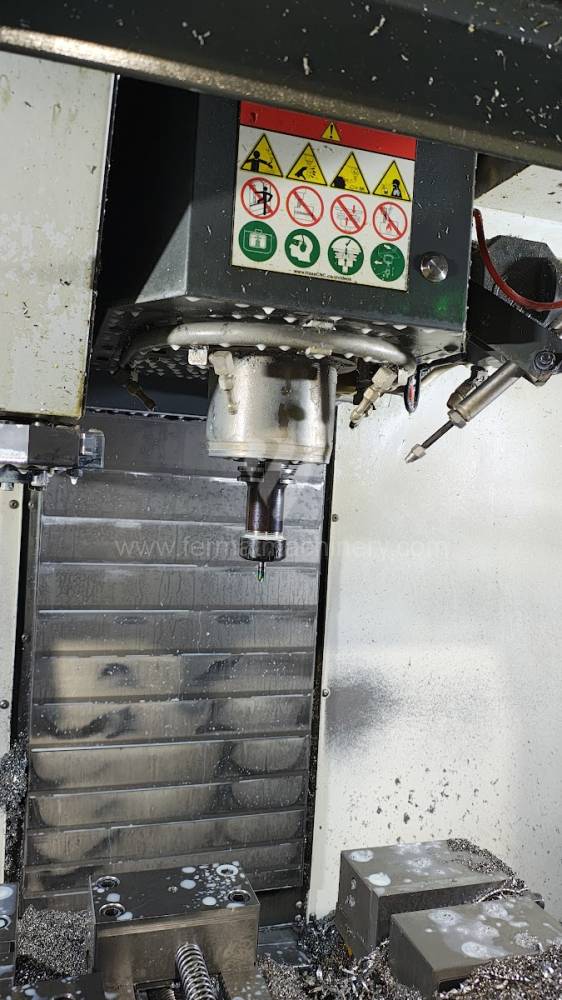

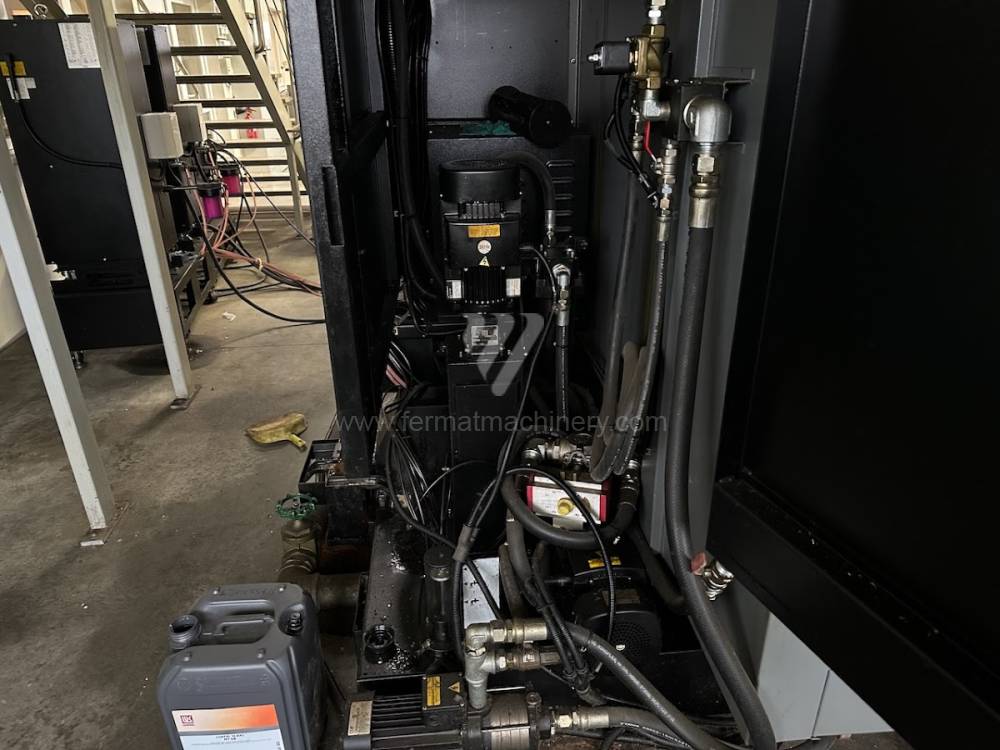

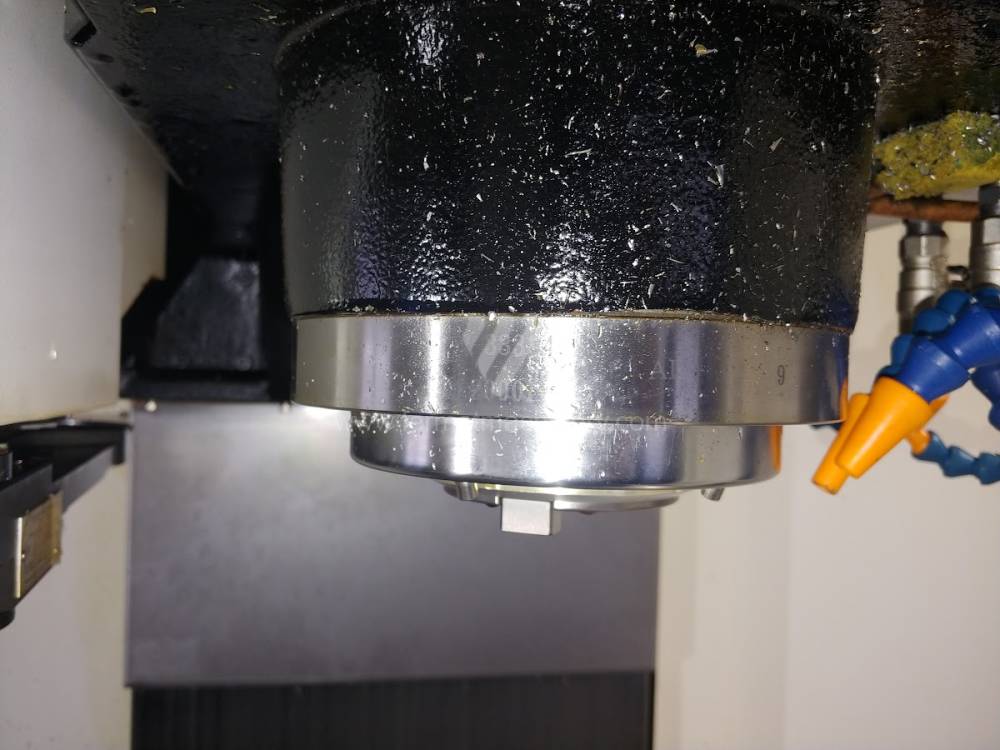

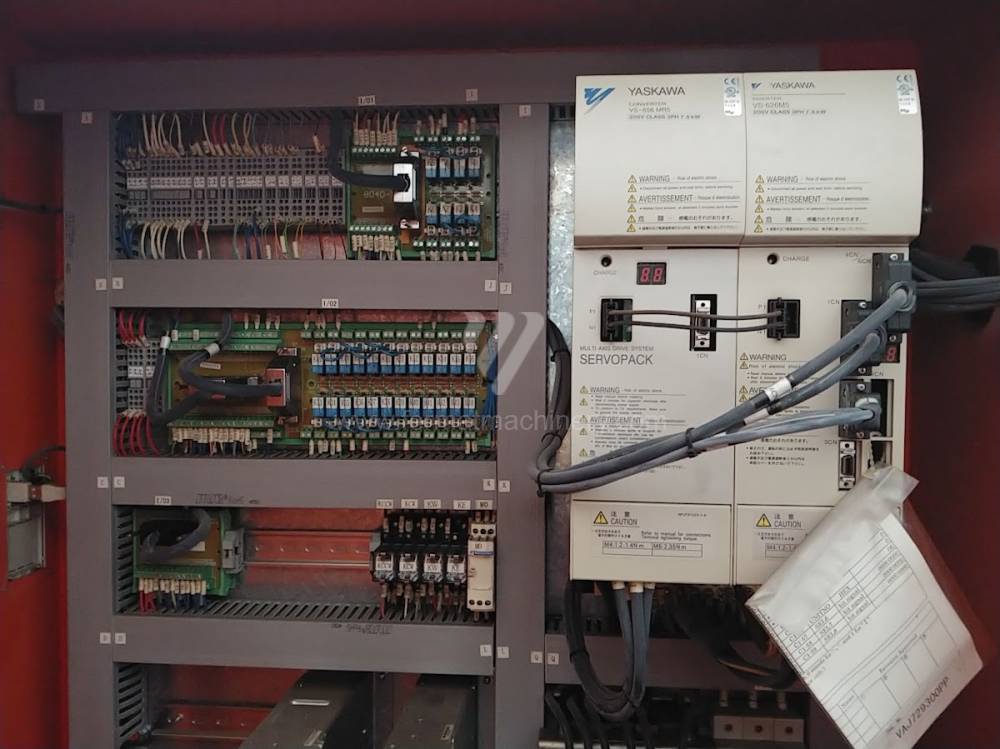

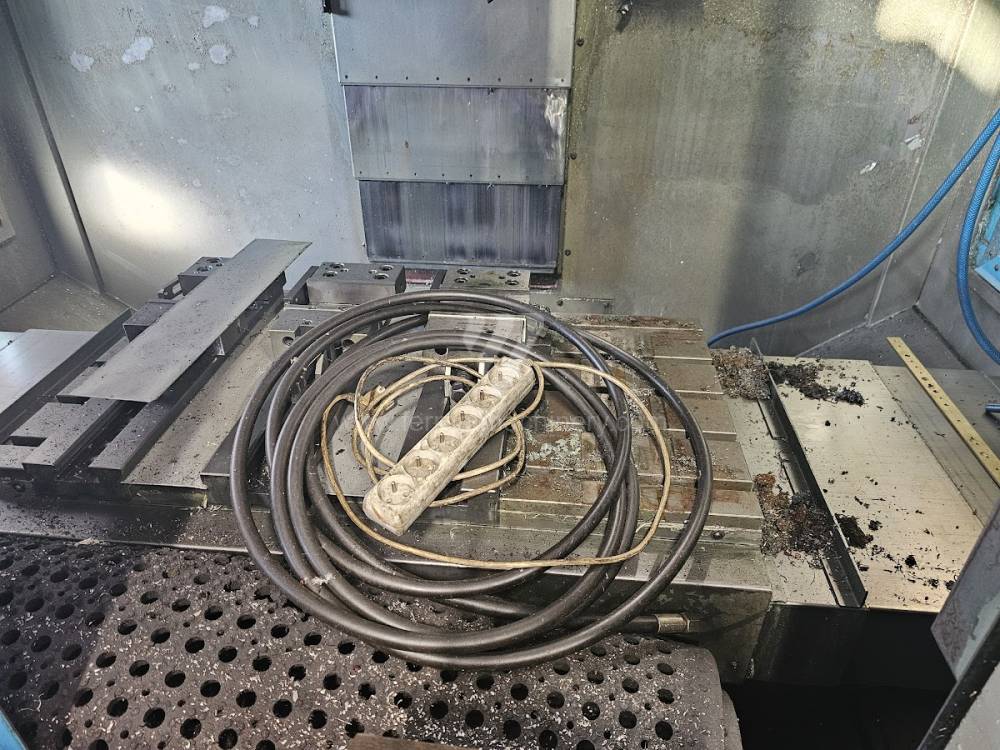

The machining center is intended for milling, drilling, boring, threading. These centers are highly productive machines for complex chip machining of metals, wood, plastic, rubber, teflon, graphite or glass.

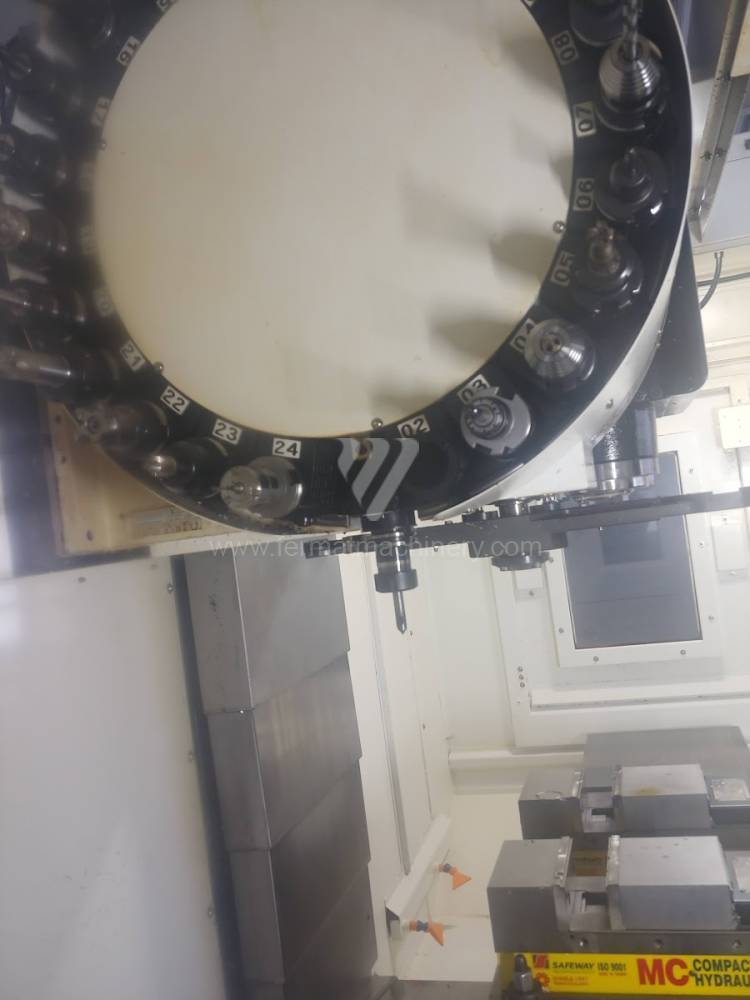

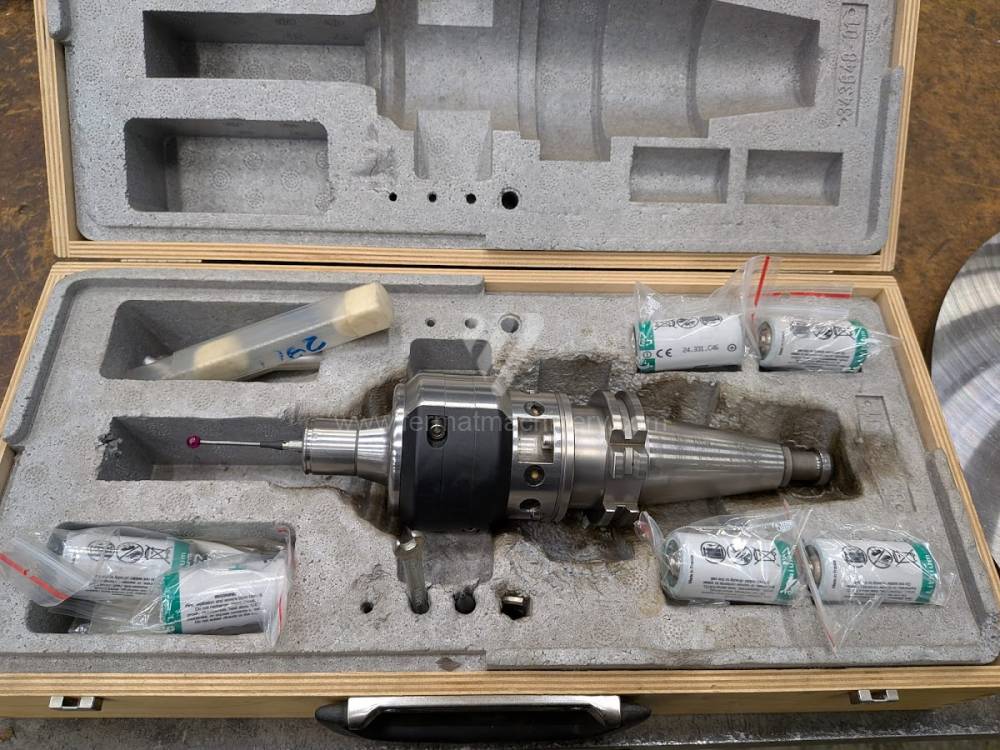

The basic design has 3 CNC axes controlled X,Y,Z. Is equipped with an automatic tool changer. These machines can be also equipped with 4th and 5th CNC controlled axes.

The most interesting group of machining centers are 5th axis machines which have simultaneously controlled X,Y,Z,B and C axes and thus they can be used to produce the most complex shapes, such as turbine blades, molds and other technologically demanding workpieces.

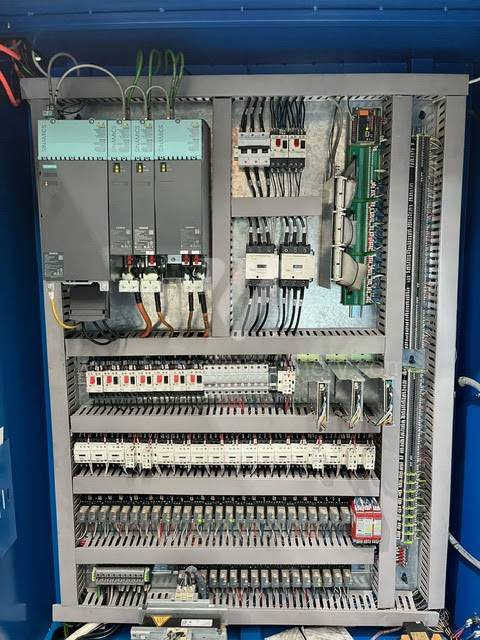

Machines are controlled with a control system. Among the most popular control systems are: Heidenhain, Siemens, Fanuc, Mazatrol or HAAS.

The most popular producers or machining centers we can talk about are Hermle, DMG MORI, MAZAK, Doosan, Fanuc, HAAS, Kovosvit MAS, Okuma, Tajmac-ZPS and many others.

According to the position of the spindle we can differentiate machining centers on vertical or horizontal.