Close

YOM:2004

Control system Siemens: Simatic OP17

Max. diameter of grinding: 400 mm

Max. length of grinding: 1500 mm

Max. weight of workpiece: 500 kg

Device for internal grinding: YES

Machine weight: 9200 kg

YOM:1990

Max. diameter of grinding: 280 mm

Max. length of grinding: 1000 mm

Max. weight of workpiece: 60 kg

Device for internal grinding: YES

Machine dimensions l x w x h: 3775x2300x2000 mm

Machine weight: 3250 kg

YOM:1991

Max. length of grinding: 630 mm

Max. width of grinding: 230 mm

Max. workpiece height: 500 mm

Spindle bearing grinders: Vertikální

Machine dimensions l x w x h: 2710 x 1495 x 1670 mm

Machine weight: 2200 kg

Max. diameter of grinding: 250 mm

Max. length of grinding: 1500 mm

Max. weight of workpiece: kg

Device for internal grinding: NO

Max. height of grinding: 125 mm

Table dimensions: 2060 x 140 mm

YOM:2007

Control system Siemens: Sinumerik 840 D

Max. diameter of grinding: 350 mm

Max. length of grinding: 600 mm

Max. weight of workpiece: 80 kg

Device for internal grinding: NO

Travel X-axis: 400 mm

YOM:2022

Control system Siemens: Sinumerik 840D Sl

Max. diameter of grinding: 500 mm

Max. length of grinding: 2000 mm

Max. weight of workpiece: 500 kg

Device for internal grinding: YES

Main motor power: 11 kW

YOM:1983

Max. diameter of grinding: 500 mm

Max. length of grinding: 1800 mm

Max. weight of workpiece: 250 kg

Machine dimensions l x w x h: 4720 x 2100 x 1750 mm

Machine weight: 7800 kg

Main motor power: 12,5 kW

YOM:2016

Max. diameter of grinding: 300 mm

Max. length of grinding: 600 mm

Max. weight of workpiece: 150 kg

Device for internal grinding: YES

Grinding spindle speed: 10 - 300 /min

Main motor power: 3,7 kW

Max. length of grinding: 1000 mm

Max. width of grinding: 320 mm

Max. workpiece height: 350 mm

Spindle bearing grinders: Horizontální

Main motor power: 4 kW

Total input: 6,8 kVA

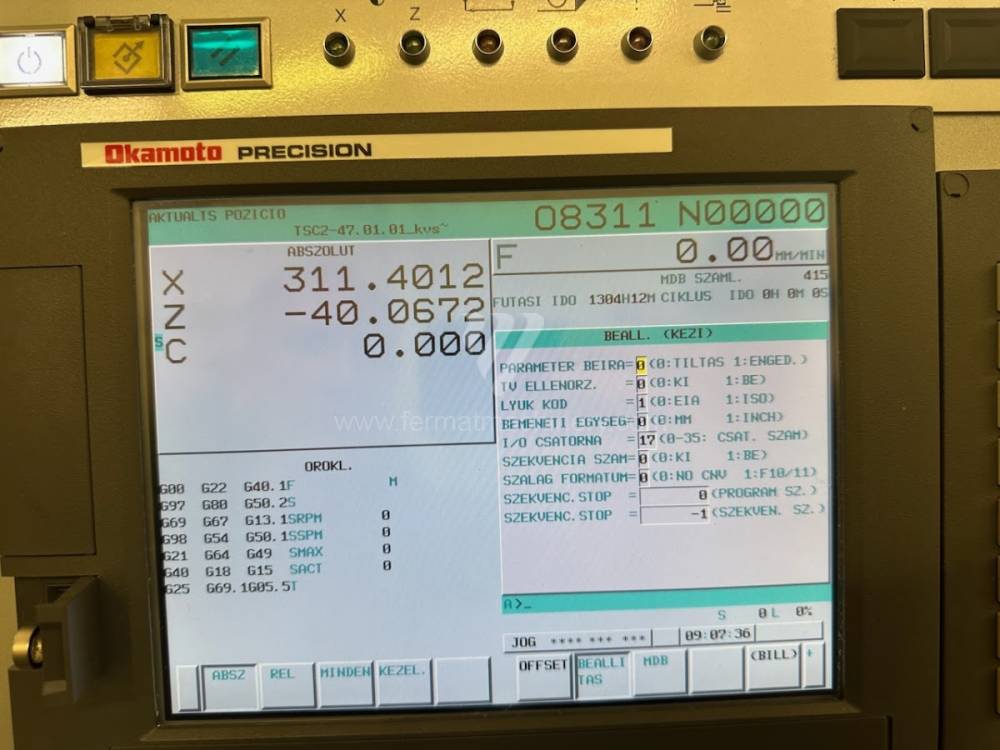

YOM:2011

Control system Fanuc: 0i - TC

Max. diameter of grinding: 190 mm

Max. length of grinding: 400 mm

Max. weight of workpiece: 80 kg

Device for internal grinding: YES

Machine dimensions l x w x h: 2500 x 1900 x 1800 mm

YOM:2009

Control system Siemens: Sinumerik 840D Sl

Max. diameter of grinding: 500 mm

Max. length of grinding: 2000 mm

Max. weight of workpiece: 500 kg

Device for internal grinding: NO

Main motor power: 11 kW

YOM:1983

Max. diameter of grinding: 250 mm

Max. length of grinding: 1500 mm

Max. weight of workpiece: 300 kg

Device for internal grinding:

Distance between centres: 1500 mm

Machine dimensions l x w x h: 6220 x 2370 mm

YOM:1984

Max. length of grinding: 2000 mm

Max. width of grinding: 650 mm

Max. workpiece height: 550 mm

Spindle bearing grinders: Horizontální

Machine weight: 15500 kg

Machine dimensions l x w x h: 6000x2400x2900 mm

Max. diameter of grinding: 160 mm

Max. length of grinding: 250 mm

Max. weight of workpiece: 10 kg

Device for internal grinding: YES

Machine dimensions l x w x h: 1900x1100x1500 mm

Machine weight: 1400 kg

YOM:1965

Min. diameter of grinding: 1 mm

Max. diameter of grinding: 25 mm

Main motor power: 4,5 kW

Machine dimensions l x w x h: 1580x870x1260 mm

Machine weight: 1800 kg

Max. length of grinding: 1000 mm

Max. width of grinding: 300 mm

Max. workpiece height: 350 mm

Spindle bearing grinders: Horizontální

Table dimensions: 300x1000 mm

Main motor power: 7,5 kW

YOM:2005

Max. length of grinding: 1500 mm

Max. width of grinding: 700 mm

Max. workpiece height: mm

Spindle bearing grinders: Horizontální

Main motor power: 18 kW

Max. diameter of grinding: 200 mm

Max. length of grinding: 450 mm

Max. weight of workpiece: 45 kg

Device for internal grinding: NO

Machine dimensions l x w x h: 2790 x 1570 mm

Machine weight: 2100 kg

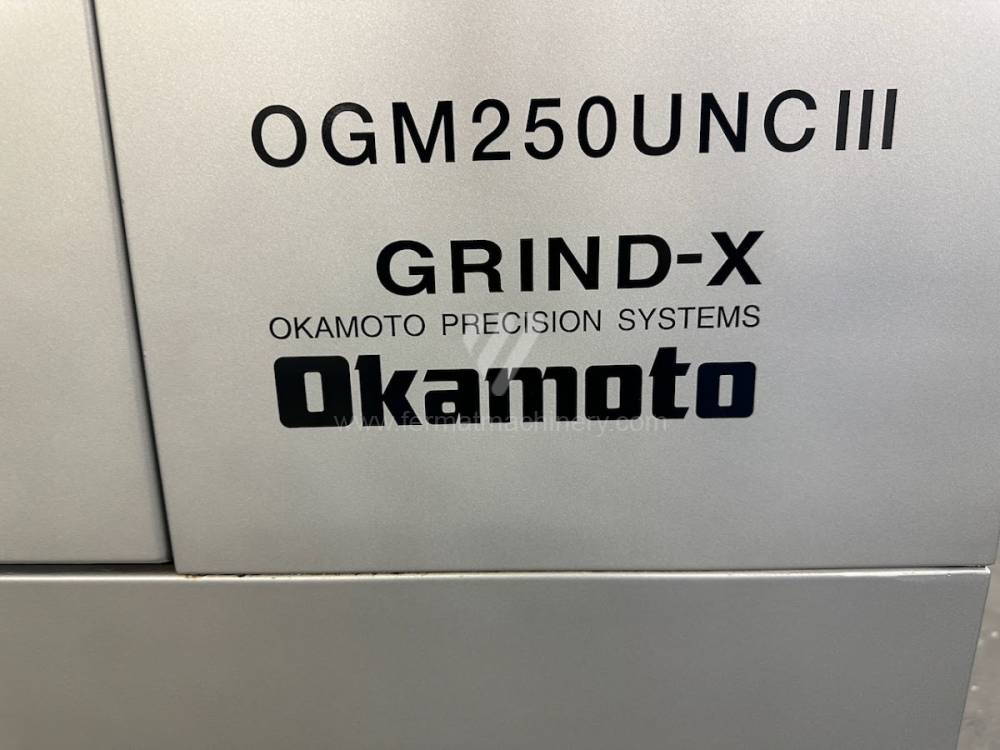

YOM:2022

Control system Fanuc:

Max. diameter of grinding: 200 mm

Max. length of grinding: 500 mm

Max. weight of workpiece: 50 kg

Device for internal grinding: NO

Travel X-axis: 215 mm

YOM:2015

Max. length of grinding: 600 mm

Max. width of grinding: 400 mm

Max. workpiece height: 375 mm

Spindle bearing grinders: Horizontální

Main motor power: 3,7 kW

Machine dimensions l x w x h: 3000x28002500 mm

YOM:1984

Max. length of grinding: 500 mm

Max. width of grinding: 230 mm

Machine weight: 2500 kg

YOM:2008

Max. length of grinding: 10000 mm

Max. width of grinding: 1795 mm

Max. workpiece height: 1200 mm

Spindle bearing grinders: Vertikální

Machine weight: 70000 kg

Machine dimensions l x w x h: 25200x10000x5100 mm

YOM:1985

Max. diameter of grinding: 400 mm

Max. length of grinding: 1500 mm

Max. weight of workpiece: 250 kg

Device for internal grinding: YES

Main motor power: 7,5 kW

Machine weight: 5950 kg

YOM:1987

Max. diameter of grinding: 630 mm

Max. length of grinding: 3000 mm

Max. weight of workpiece: 2500 kg

Device for internal grinding: NO

Total input: 31 kVA

Machine weight: 14900 kg

YOM:2002

Control system Siemens: Sinumerik 840 D

Max. diameter of grinding: 200 mm

Max. length of grinding: 400 mm

Max. weight of workpiece: 80 kg

Device for internal grinding: NO

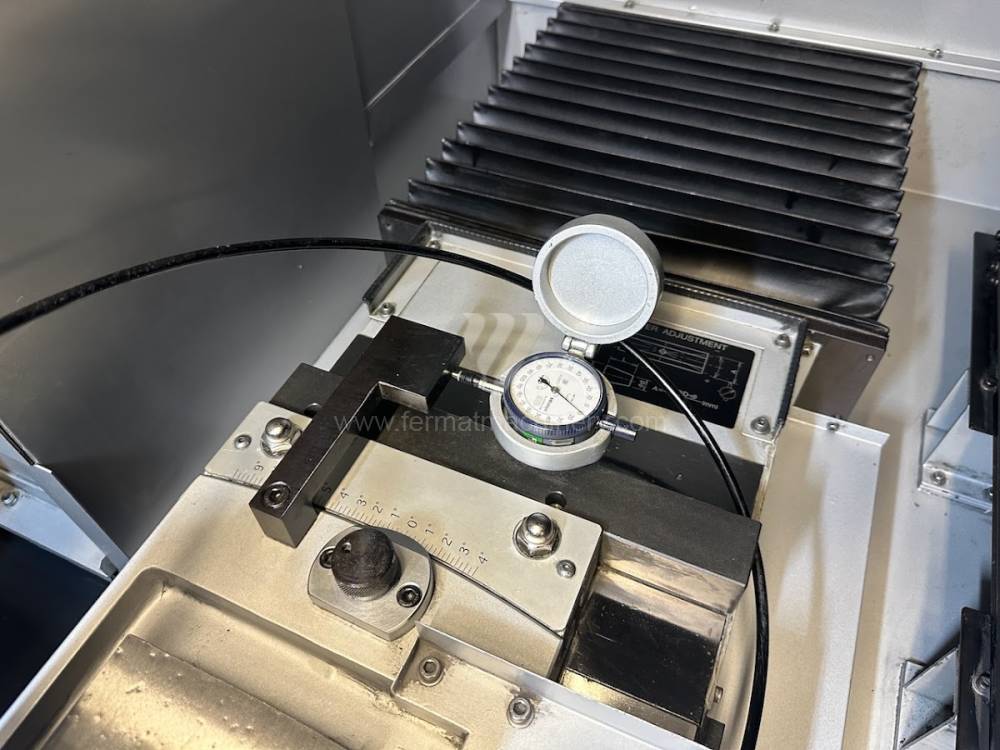

Grinding is a technology of precision chip machining. Nowadays, it is possible to reach precision in order of tenths of micrometers and surface roughness of up to 0,2 micrometer. Grinders are thus indispensable in the machinery industry and form an important part of the production process. In general, grinding is a technology that works on the principle of the material removal from the surface layer of the workpiece with fine grains of abrasive material, which are most often bonded to the grinding wheel.

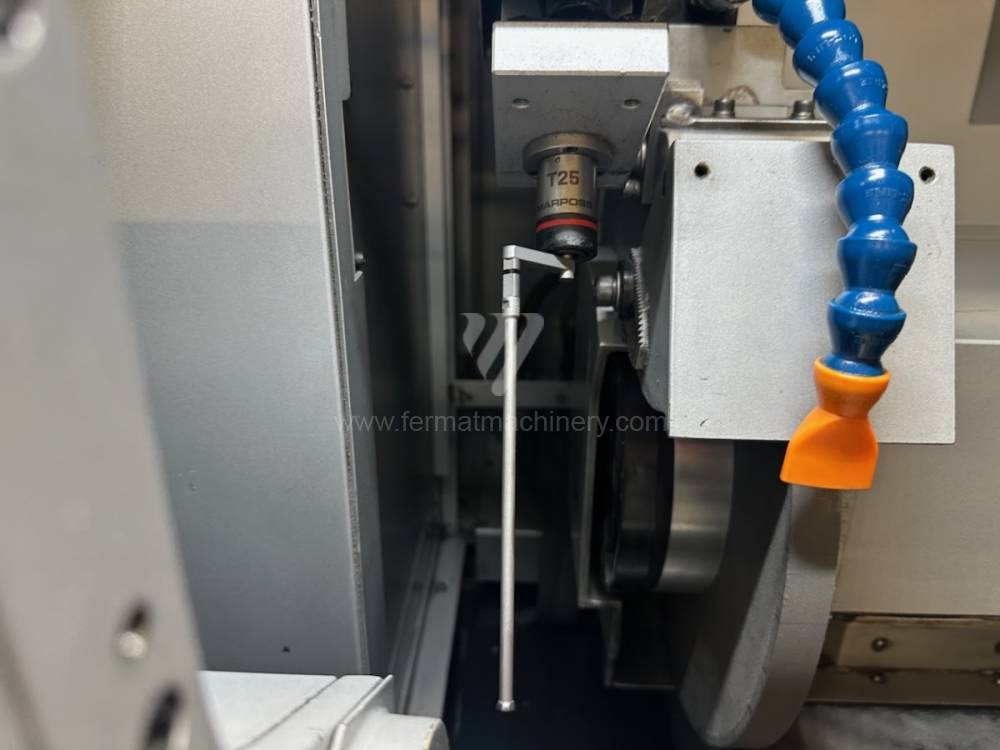

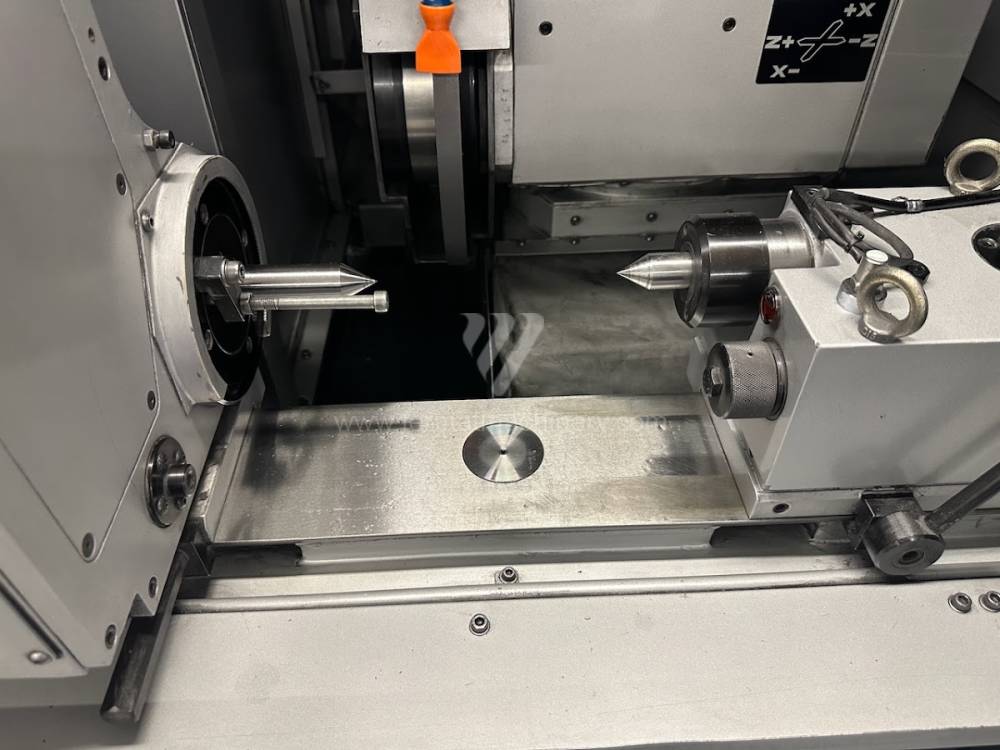

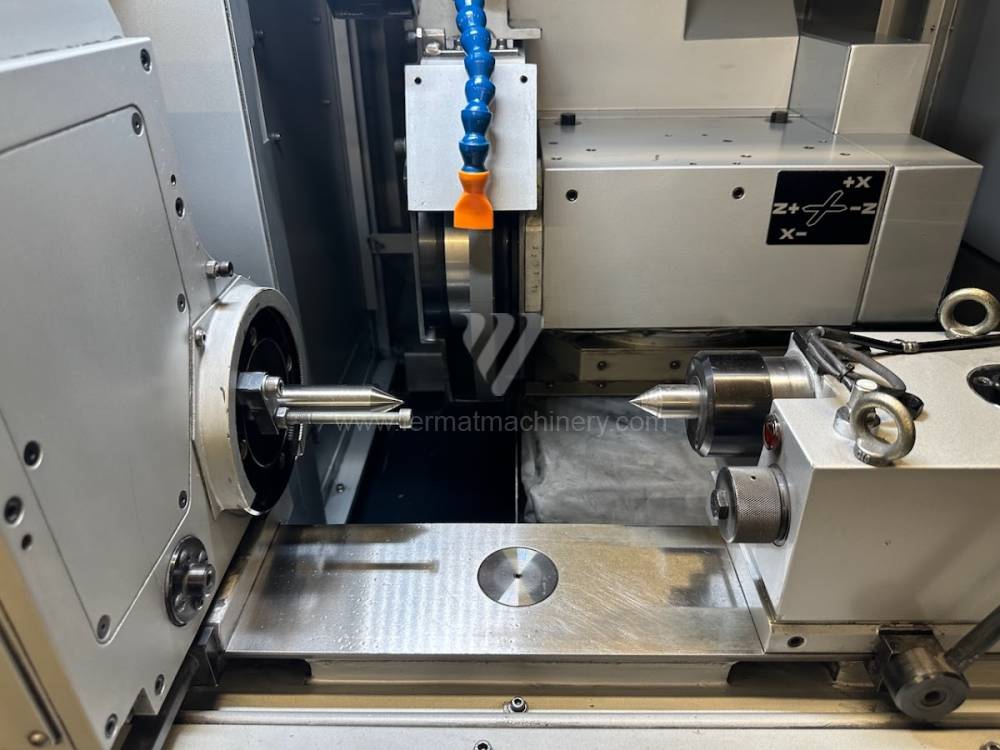

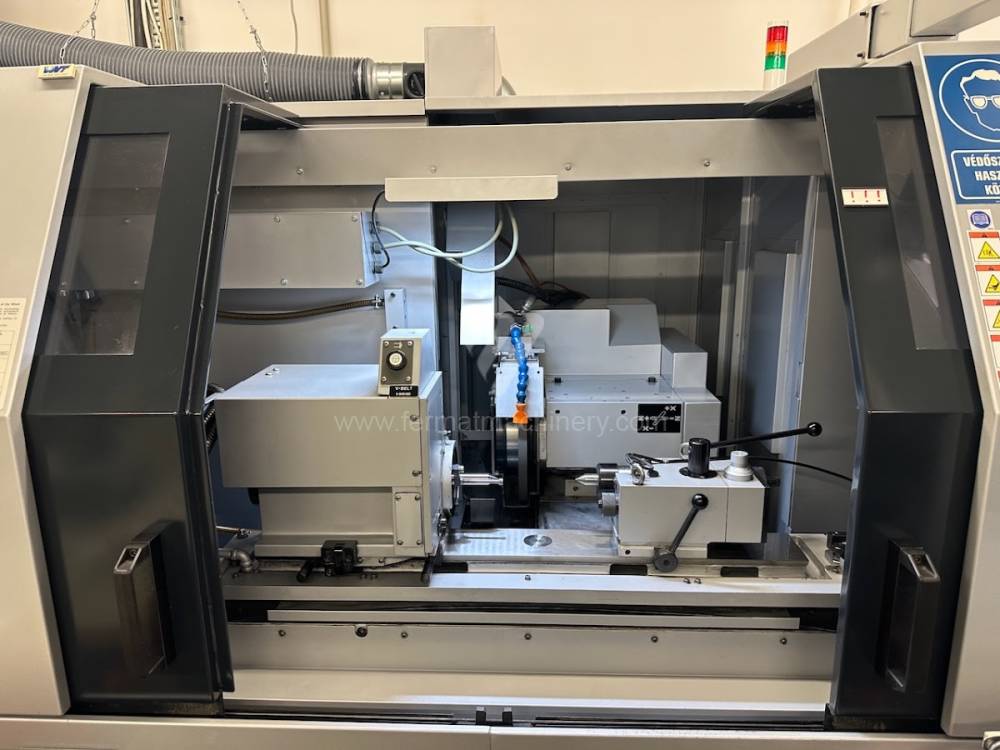

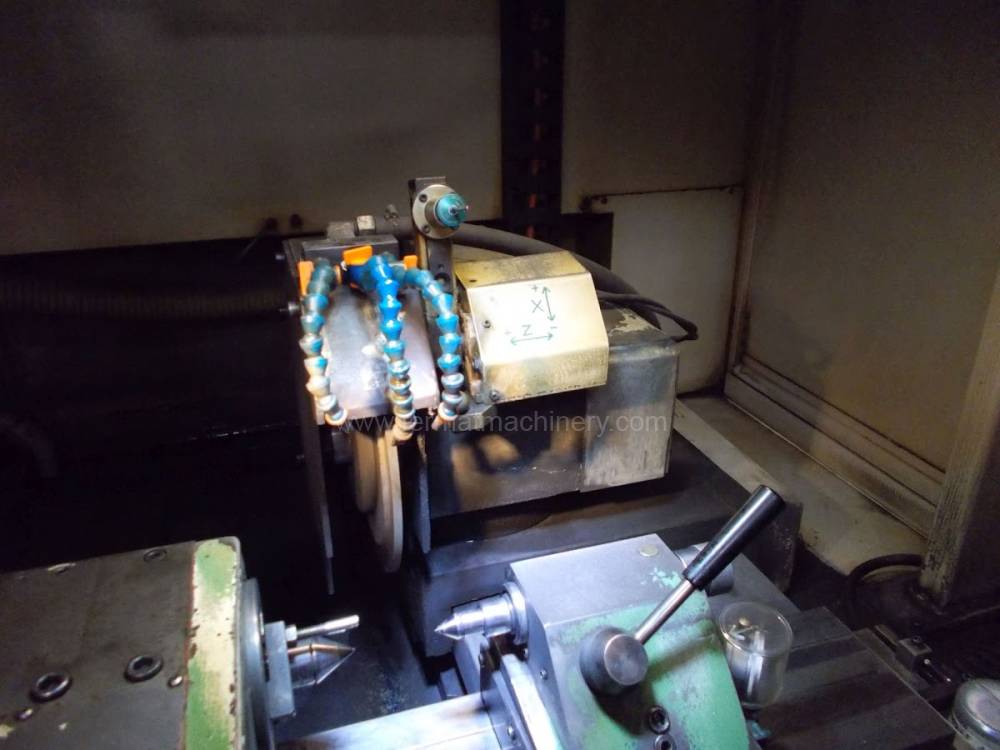

Among the cylindrical grinders we differentiate grinders with centers and without centers. These machines are used for grinding internal and external rotating surfaces.

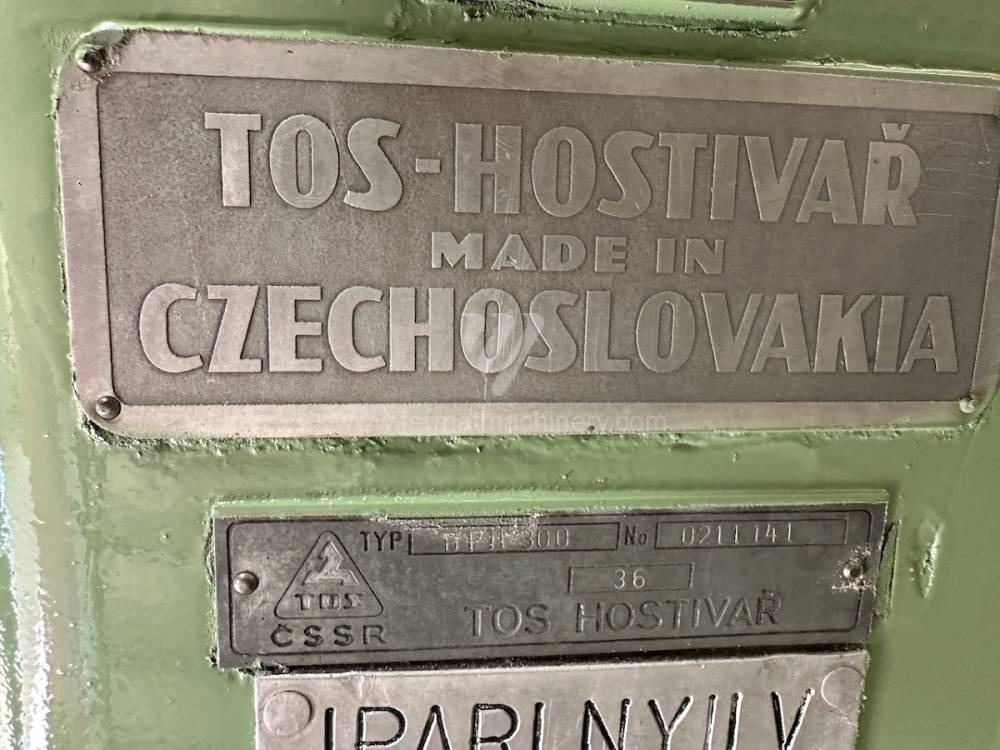

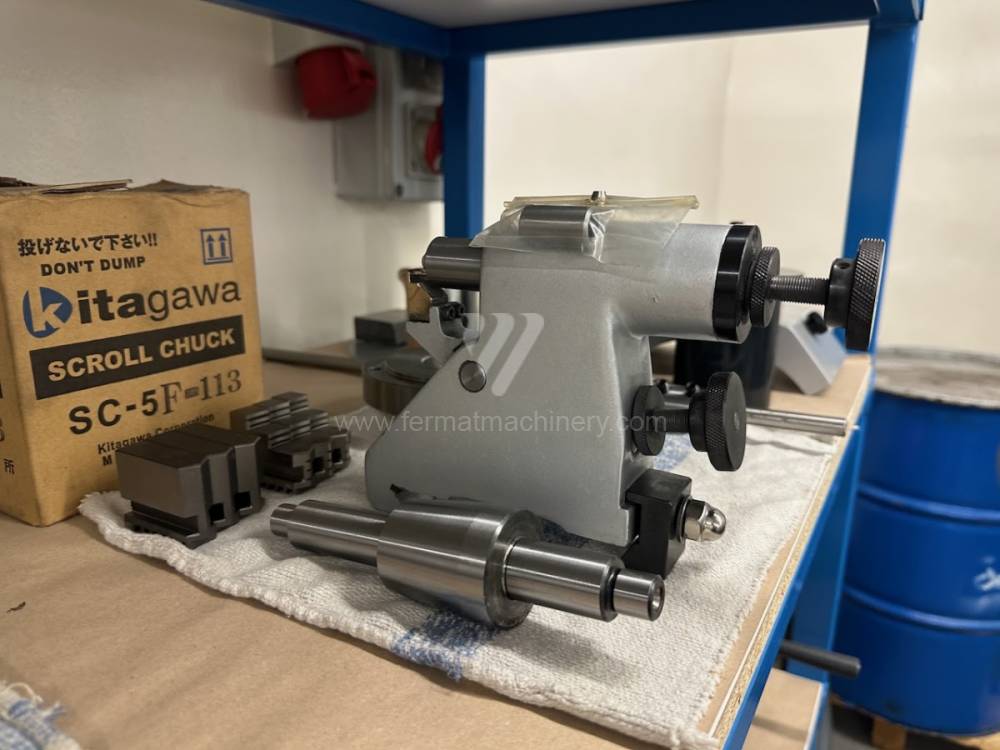

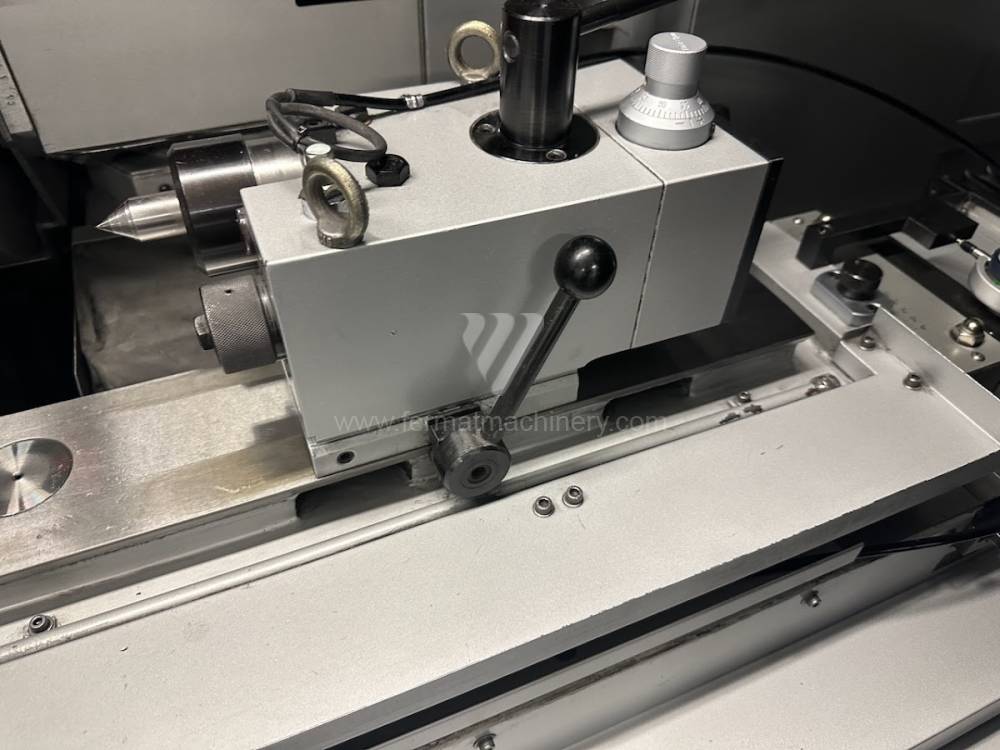

In case of center grinders the workpiece is usually clamped between centers and rotation is realized using a driver, which is fixed to the surface of the workpiece and tied to headstock. In most cases the workpiece rotates against the direction of rotation of the grinding wheel. Most common models from producer TOS we can mention:

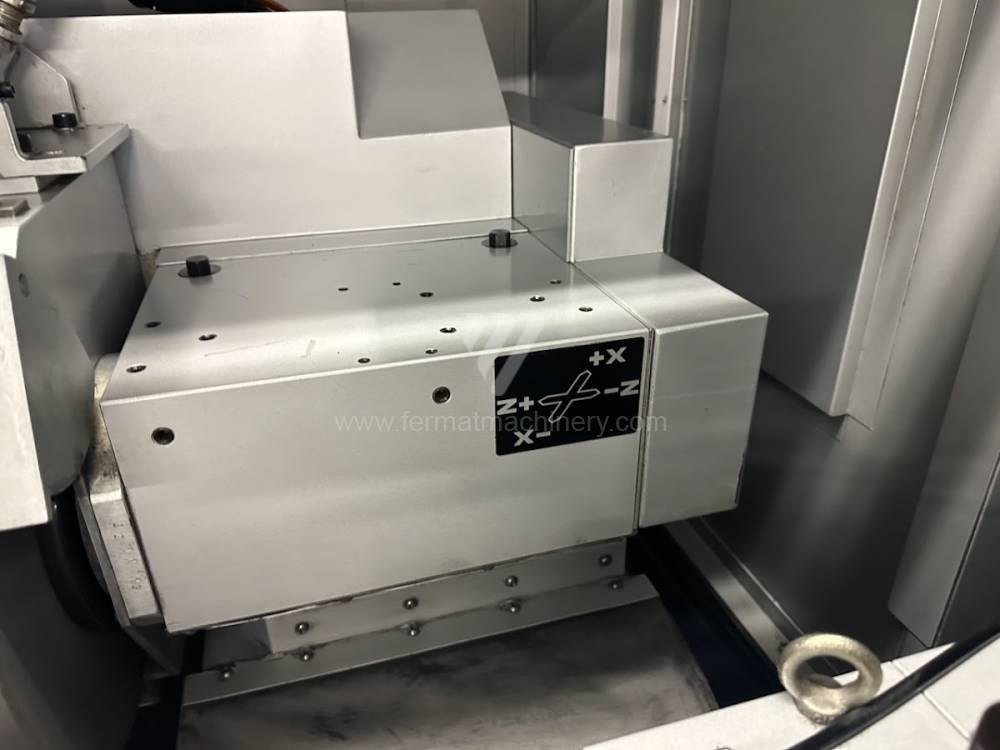

Grinding is realized using the rotation of the grinding wheel, which grinds the surface of the workpiece as it rotates. Most popular producers of such grinders are: FERMAT, TOS, STUDER, DANOBAT, KELLENBERGER, ERWIN JUNKER, SCHAUDT.

Centerless grinders are also intended for grinding rotary surfaces. The clamping of the workpiece on the machine is different. It is supported with support ruler and the workpiece is placed between two discs – abrasive and drifting. The grinding wheel usually spins faster and does the grinding itself. The drive disc is most often made of flexible material (for example rubber) and ensures sufficient pressure.

A special category of grinders are grinders used for grinding of internal rotating surfaces. They works similarly to center grinders. However, the workpiece is just clamped on one side in the chuck or collet so that the hole can be ground from the other side.