Milling/Turning solution for continuous production of pumps with high accuracy

Customer experience

- Company: MAAG Pump System, Switzerland

- Segment: Oil&Gas

- Subject: Milling/Turning solution for continuous production of pumps with high accuracy

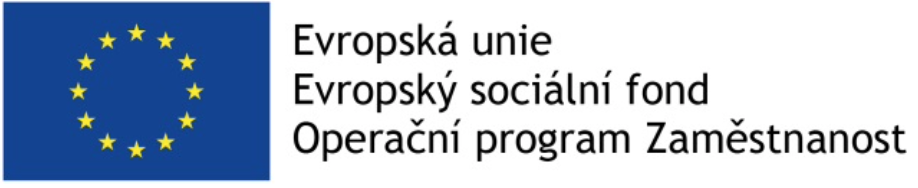

- Machine FERMAT: WRF 130 CNC X8600, Y3000, Z1000, W800, 1x 2000x2500 40T V2400, 1x D1800 25T, Robot 96

Customer Requirements

- High accuracy of machined pumps: alignment of milled surfaces within 0.025/1000, perpendicularity of bored axis of the pump against base within 0.025/1000

- Continuous production on two separated stations while maintaining operator safety, machining in one station, while un/clamping in the other

- Most advanced technical solution regarding technological functions

Points of Technical Solution

- Increased accuracy of the machine, detailed choice of components acc. to accuracy, more accuracy-demanding methods in production of main components, application of 3D volumetric compensation

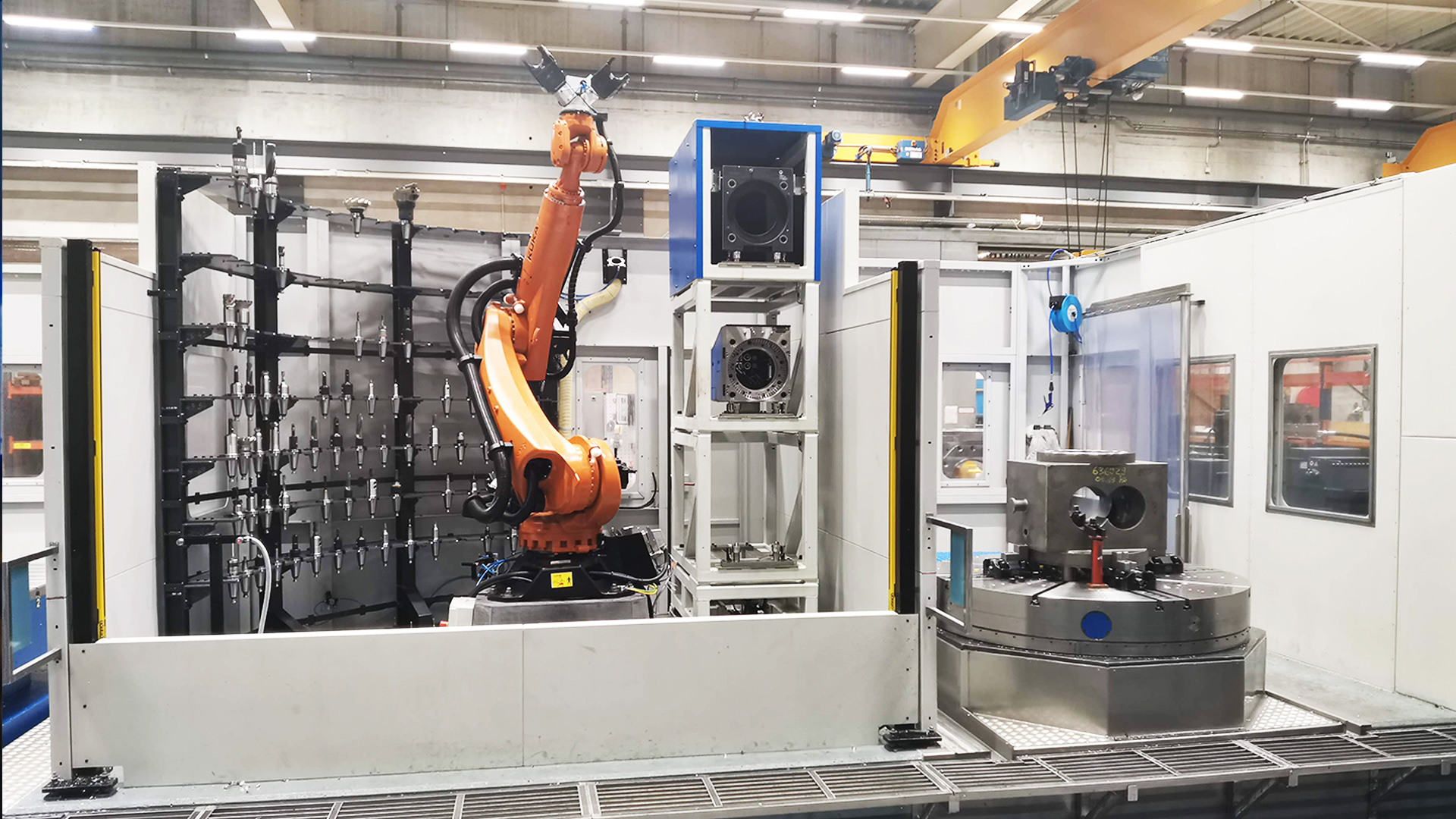

- Two independent stations for continuous production, turning and milling zone, safety elements, secondary control panels, second primary control panel

- Multitasking solution, full-scale solution for turning and milling operations, tapping, continuous 4-axis machining, boring, etc.

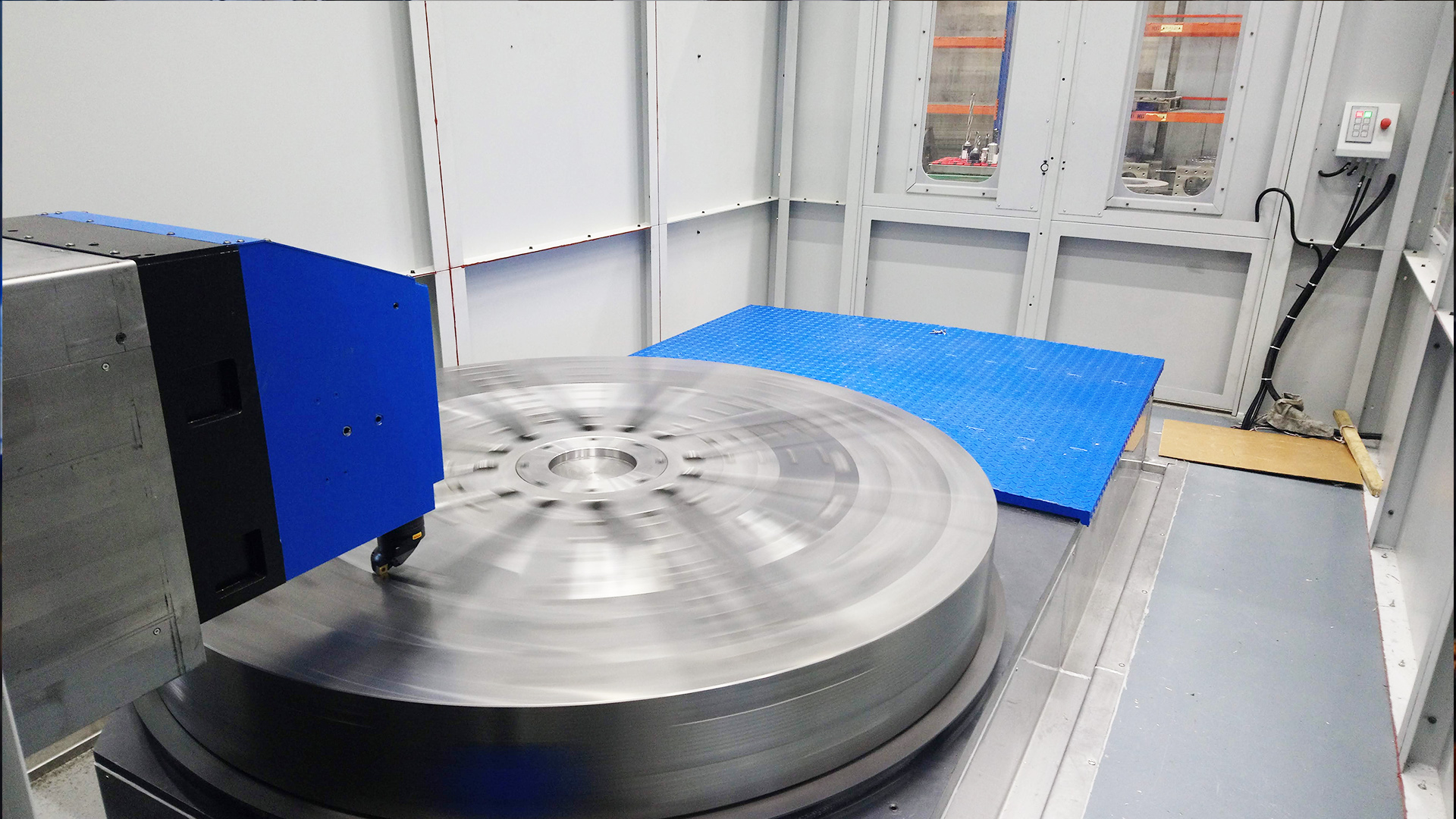

- Turning station: turning table D= 1800 mm, 250 rpm, max load capacity 25t, possibility of turning/indexing/continuous milling, automatically loaded turning adapter with CAPTO C8 + automatic tool exchange

- Milling station: 2000 x 2500 mm, 2.5 RPM, max. load capacity 40t, possibility of turning/indexing/continuous milling

- FERMAT Robotic: combined exchange for 96 tools ISO50 + Capto C8, integrated PICK-UP station for three positions (for heads/adapters/cover plates)

- Angle head with two axes, controlled with servomotors for fast positioning, possibility of continuous movement of rotary axes

- Technological elements: latest version of control system SIEMENS 840D Operate, full-scale kinematic chain, anti-collision system, laser touch probe RENISHAW, laser detection of broken tool by means of KUKA robot, turning technology ShopTurn, controlled compensation of ram deflection

Gallery

+420 774 339 356

RUS | WhatsApp

RUS | WhatsApp

+39 366 755 2010

ITA | WhatsApp

ITA | WhatsApp

Or leave us your phone number and we will take care of everything for you

By clicking the button "Call me"

I give consent to use my personal details above

for marketing purposes and I declare I am more than 16 years of age.

Česky

Česky

Deutsch

Deutsch