Applikationsunterstützung

Service und Ersatzteile

Neumaschinen

Der Hauptteil unserer Produktion sind horizontale Bohr- und Fräsmaschinen, die wir seit unseren Anfängen produzieren, als wir die erste Maschine der WRF-Serie bauten. Mit der Entwicklung des Marktes und damit auch von FERMAT wurde das Produktionsportfolio auch um andere Produktreihen erweitert. Wir bieten Sicherheit und vollständige technische Verarbeitung, einschließlich Produktionsübergabe::

Tischbohrwerke

Die Tischhorizontalbohrwerke der Serie mit Quertischverstellung sind für die Bearbeitung kleiner und mittlerer Werkstücke bis 50 Tonnen ausgelegt.

Plattenbohrwerke

Horizontale Plattenbohrwerken mit Querverstellung des Ständers sind für die Bearbeitung großer Werkstücke bis 100 Tonnen ausgelegt.

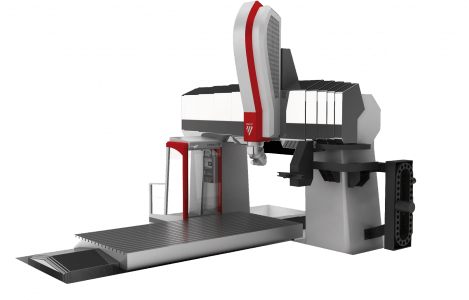

Gantrymaschinen und Portalmaschinen

Portalmaschinen im Design mit einem verfahrbaren Portal oder mit einem verfahrbarenTisch mit einer großen Auswahl an Zubehör.

Lagermaschinen

Maschinen mit verkürzter Lieferzeit, teilweise oder vollständig in der Montagehalle montiert oder auf Lager zerlegt.

Schleifmaschinen

Die universelle Rundschleifmaschinen FERMAT Machine Tool

Zubehör

Große Auswahl von automatischen oder manuellen Fräsköpfen, Planscheiben und anderem Zubehör.

Applikationsunterstützung

Ein erstklassiger Kundenservice ist für uns selbstverständlich. Wir bei FERMAT wissen, dass die Servicequalität auf die Kundenzufriedenheit großen Einfluss hat.Wir versuchen deshalb kontinuierlich unsere Leistungen in diesem Bereich und den Informationsfluss bei Servicefällen zu verbessern.

Lösung fur Ihre Herstellungoptimierung

Service und Ersatzteile

Guter Service basiert auf guten Leuten. Seit den Anfängen im Jahr 1990 legen wir großen Wert auf hohe Servicequalität und schnelle Lieferung von Ersatzteilen.

Bewertung den Kunden

und was für Erfahrung haben die mit unsere Maschinen

Lakics stellt große Teile für Windgeneratoren her. Unsere Zusammenarbeit mit FERMAT begann vor mehr als 10 Jahren und dauert bis heute an, weil sie präzise und zuverlässige Maschinen produzieren. Derzeit haben wir 7 Bohrmaschinen von FERMAT.

LAKICS

Jr. László Lakics, GeschäftsführerNordmark stellt hauptsächlich Teile für Windkraftanlagen her. Wir haben eine sehr gute Beziehung zu FERMAT, unserem Lieferanten von Horizontalbohrwerken, und mit Hilfe seiner Maschinen haben wir viele präzise Teile hergestellt. Und das ist das Wichtigste - eine gute Zusammenarbeit, die für beide Seiten von Vorteil ist, sowohl für Nordmark als auch für FERMAT.

NORDMARK

Michael Jacobsen, Gründer des Unternehmens RUS | WhatsApp

RUS | WhatsApp

ITA | WhatsApp

ITA | WhatsApp

oder geben Sie uns Ihre Telefonnummer und wir kümmern uns um alles für Sie

Klicken Sie auf die Taste "Rufen Sie uns an"

Ich erkläre mich damit einverstanden, meine oben genannten persönlichen Daten zu verwenden

für Marketingzwecke und ich bestätigen hiermit, dass ich mehr als 16 Jahre alt bin.

Wir sind eine Familie im Fermat

FERMAT wurde in 1990 von Jiří Ferenc und Herr Matys, dessen Nachnamen zur Bildung des Firmennamens verwendet wurden, gegründet . FERMAT hat von Anfang an von der soliden Berufsethik von Familie und Freunden profitiert, um seine Exzellenz zu steuern.

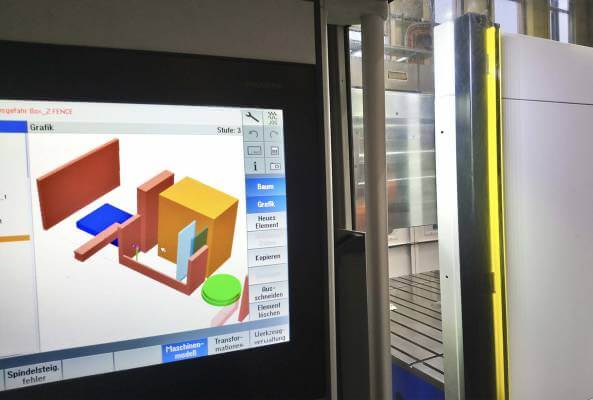

Wir verwenden auf allen unseren Maschinen die neueste Technologie

Wir verwenden in allen unseren Maschinen Spitzentechnologien und sind stets bemüht, neue Technologien zu entwickeln, die unser modulares Konzept der Fertigung und das Know-how für Werkzeugmaschinen integrieren. Ein Beispiel ist unser neues 5-Achsen-Multitask-Portal.

Česky

Česky

English

English